Equipment without downward bending and cooling used for plastic extrusion molding

An extrusion molding and plastic technology, which is applied in the field of equipment that does not require bending cooling, can solve problems such as affecting the installation of molding plastic strips, and achieve the effects of preventing left and right swinging, efficient cooling and shaping, and improving cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

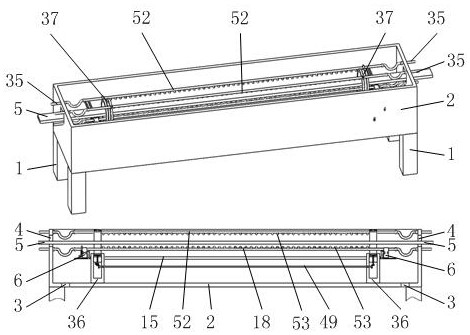

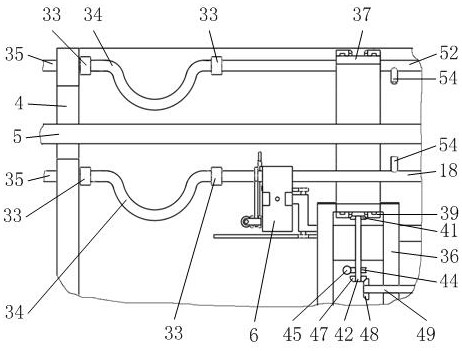

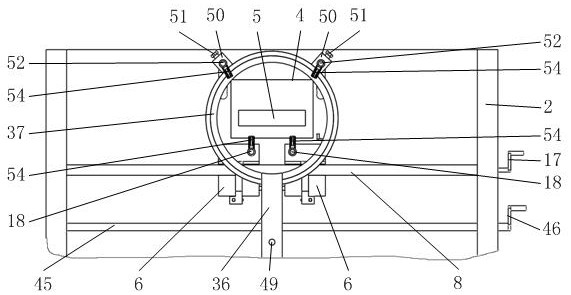

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0036] Such as figure 1 , 2 , 3, it includes water receiving tank 2, water pipe A18, ring sleeve B37, ring B39, fixed sleeve 50, bolt 51, water pipe C52, nozzle mechanism 54, wherein as figure 1 , 3 As shown, two steel water pipes A18 which cool the lower surface of the plastic strip 5 and are parallel to the movement direction of the plastic strip 5 are symmetrically installed in the water receiving tank 2, and two steel pipes A18 which cool the upper surface of the plastic strip 5 and are parallel to the movement direction of the plastic strip 5 Parallel steel water pipes C52; two water pipes A18 are on the same horizontal plane, and two water pipes C52 are on the same horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com