Hydraulic rock breaking process capable of continuously splitting rock at multiple points in drill hole

A technology for drilling inside and out of rock, which is applied in the field of rock hydraulic rock breaking technology, which can solve the problems of low rock breaking efficiency and achieve the effects of improving the splitting rock breaking efficiency, increasing the splitting thrust, and deepening the splitting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

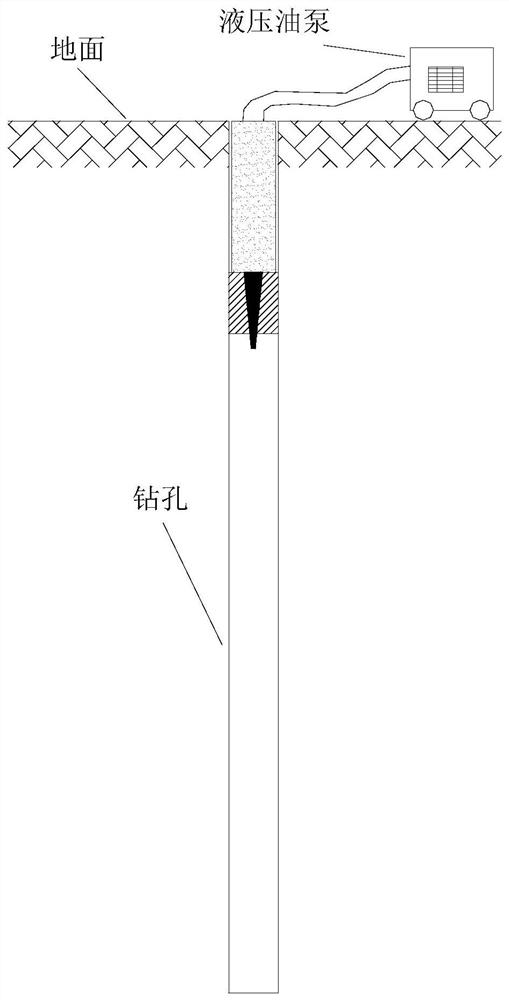

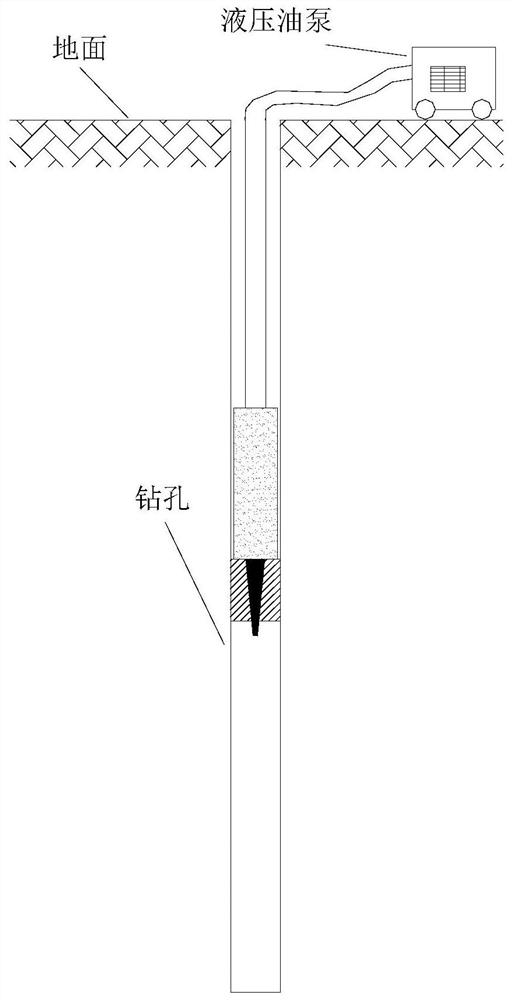

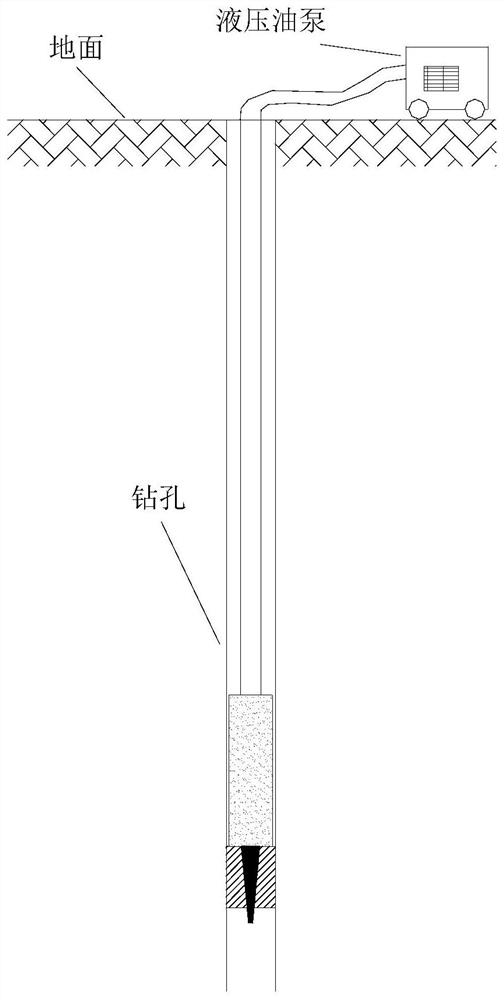

[0034] exist Figure 1~3 Among them, the present invention relates to a rock hydraulic rock breaking process capable of continuous multi-point splitting in a borehole, which consists of the following steps:

[0035] A. Drilling: A drilling rig is used to pre-drill several holes on the rock surface, and the hole diameter is larger than the outer diameter of the splitting gun based on multi-stage serial hydraulic cylinders;

[0036] B. Oil circuit connection: connect the splitting gun based on the multi-stage serial hydraulic cylinder to the hydraulic pump station on the ground next to the drilling hole;

[0037] C. Splitting gun into the hole: Insert the splitting gun into the hole inside the drill hole by mechanical or manual means, and adjust the angle of the splitting gun in the horizontal direction in the hole according to the occurrence of the air surface to ensure that the splitting front support ( 1) The expansion direction is perpendicular to the connection direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com