Tunnel water cable trench inner film shrinkage formwork, trolley and construction method of tunnel hydroelectric cable trench inner film shrinkage formwork

A formwork trolley and water cable technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low efficiency, bumping of concrete corners, damage to the appearance quality of trenches and cable troughs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

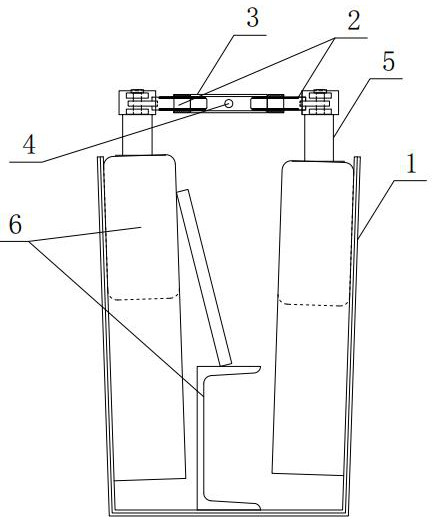

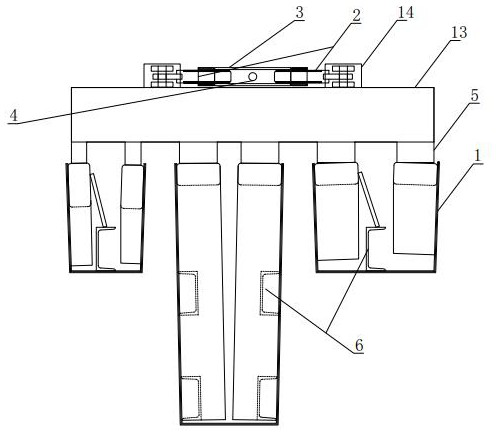

[0023] A shrinkable formwork for the inner membrane of a tunnel water cable trench, including a shrinkable cable trench formwork body 1, the shrinkable cable trench formwork body 1 is divided into three pieces, which are two side panels and a bottom panel, two side panels and a bottom panel. A bottom plate is fixedly connected, and several groups of shrinking devices are arranged longitudinally (that is, along the extension direction of the formwork body) on the upper ends of the two side plates. Composition (both ends of the sleeve are provided with internal threads, and the directions of the two sections of internal threads are opposite), the two lead screws 2 in opposite directions are disconnected in the middle and arranged on the same line, and the two-way threaded cylinder 3 can be sleeved on the two lead screws in opposite directions 2, a hole 4 is provided in the center of the two-way threaded cylinder;

[0024] The two ends of the two lead screws 2 in opposite directi...

Embodiment 2

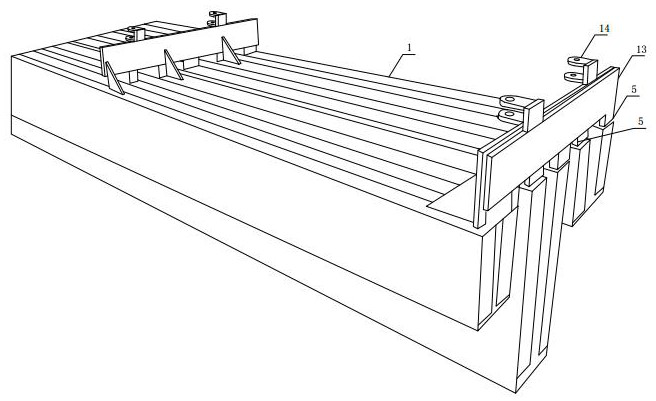

[0026] A shrinkable formwork for the inner membrane of a water cable trench in a tunnel, including a shrinkable cable trench formwork body 1, the shrinkable cable trench formwork body 1 is more than two, and a positioning plate 5 is fixedly arranged on the upper surface of each side plate, and each The positioning plate on the same side of the body is fixed on a steel plate 13, and the positioning plate 5 on the other side of each body is fixed on another steel plate 13. The two steel plates 13 are movable in parallel, and a protrusion is respectively arranged in the middle of the two steel plates. , the vertical direction of the protrusion is provided with a support 14 (the support is provided with holes, the two screw screws with opposite directions have holes, and the ends of the two screw screws with opposite directions are connected to the support by bolts), through the two support The seat 14 is provided with two lead screws 2 in opposite directions, and two-way screw cyl...

Embodiment 3

[0028] A tunnel water cable ditch formwork trolley, comprising a frame 7, the frame 7 is a rectangular frame structure with an empty middle part, a base 8 is arranged at the lower end of the frame, and is used for temporarily displaying the tunnel water cable ditch formwork trolley, and the lower end of the base 8 is arranged There are 4 wheels 9, and two sets of beam cranes 10 are arranged on the upper part of the frame 7. The beam cranes 10 are composed of a bridge frame 11 and a lifting trolley 12. The lifting trolley 12 can lift the tunnel water cable ditch formwork through the steel wire (steel wire Through the gap of the shrinking device, the inner mold can be lifted). Further, the base lower end wheel 9 is provided with a motor and a reducer, the motor is arranged on the base 8, the motor is connected with the wheel 9 through the reducer, and the wheel 9 is driven by the motor and the reducer.

[0029] A method for constructing the shrinkable formwork of the inner film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com