Mute noise reduction type bearing

A noise reduction type, bearing technology, applied in the field of bearings, can solve problems such as normal operation of workers affecting the normal operation of equipment, noise pollution of the surrounding environment, failure of motors and equipment, etc., to facilitate disassembly, ensure normal operation, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

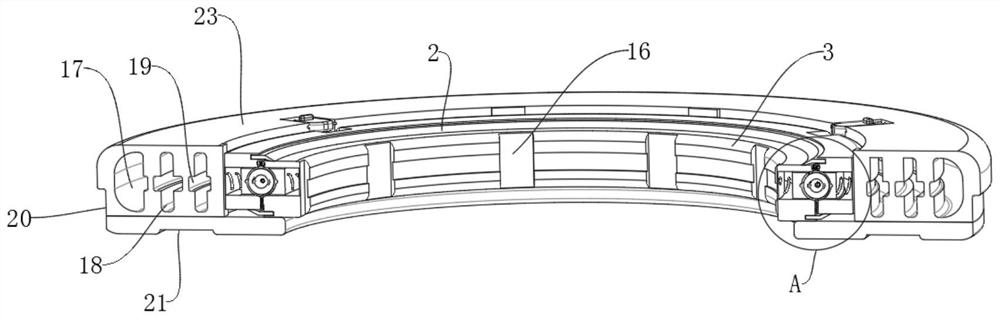

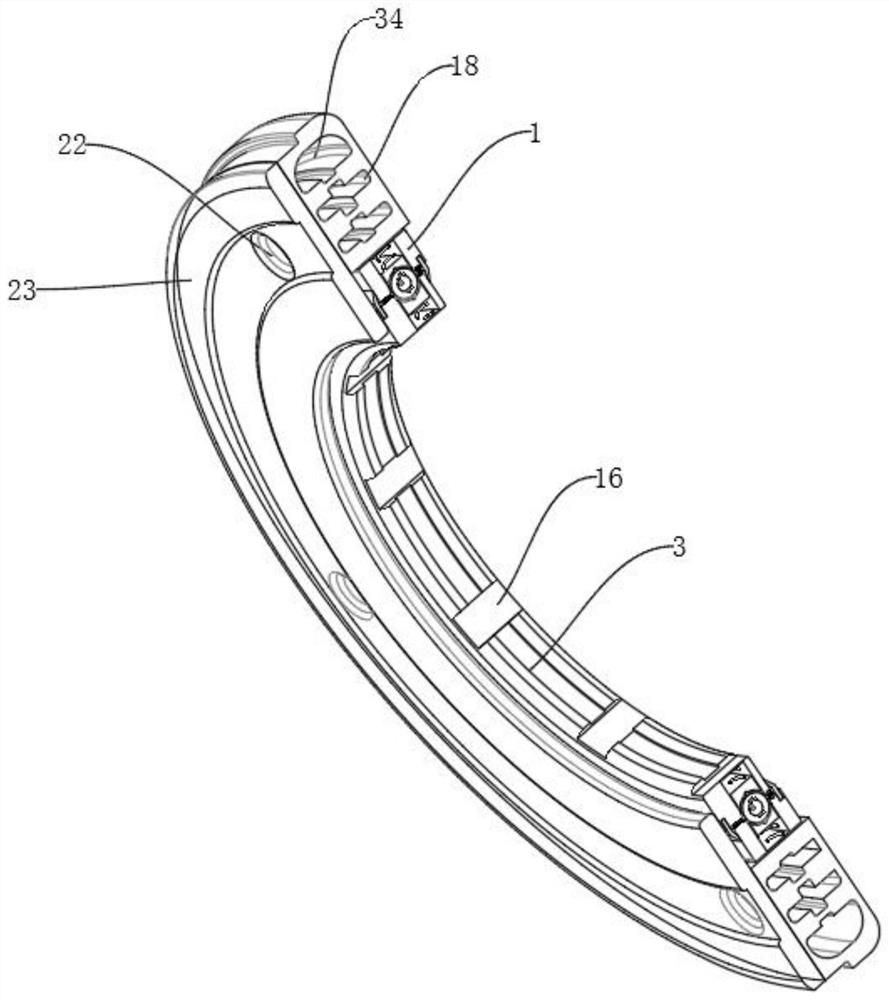

[0032] Please refer to Figure 1-6As shown, a silent and noise-reducing bearing includes a bearing outer ring 1, an outer buffer channel 4 is provided on the inner wall of the bearing outer ring 1, a bearing inner ring 3 is rotationally connected between the inner walls of the bearing outer ring 1, and the bearing inner ring 3 The outer wall of the bearing is provided with an inner buffer channel 14, the inner wall of the bearing outer ring 1 is provided with an outer annular groove 5 near the top edge, the inner wall of the outer buffer channel 4 and the inner wall of the inner buffer channel 14 are slidingly connected with a buffer block 9, two The outer wall of one side of the buffer block 9 is provided with a semicircular groove 7, and a plurality of rollers 8 slide between the two semicircular grooves 7. The outer wall of the bearing inner ring 3 is provided with an inner annular groove 15 near the edge of the bottom. One side of the semicircular groove 7 is provided with...

Embodiment 2

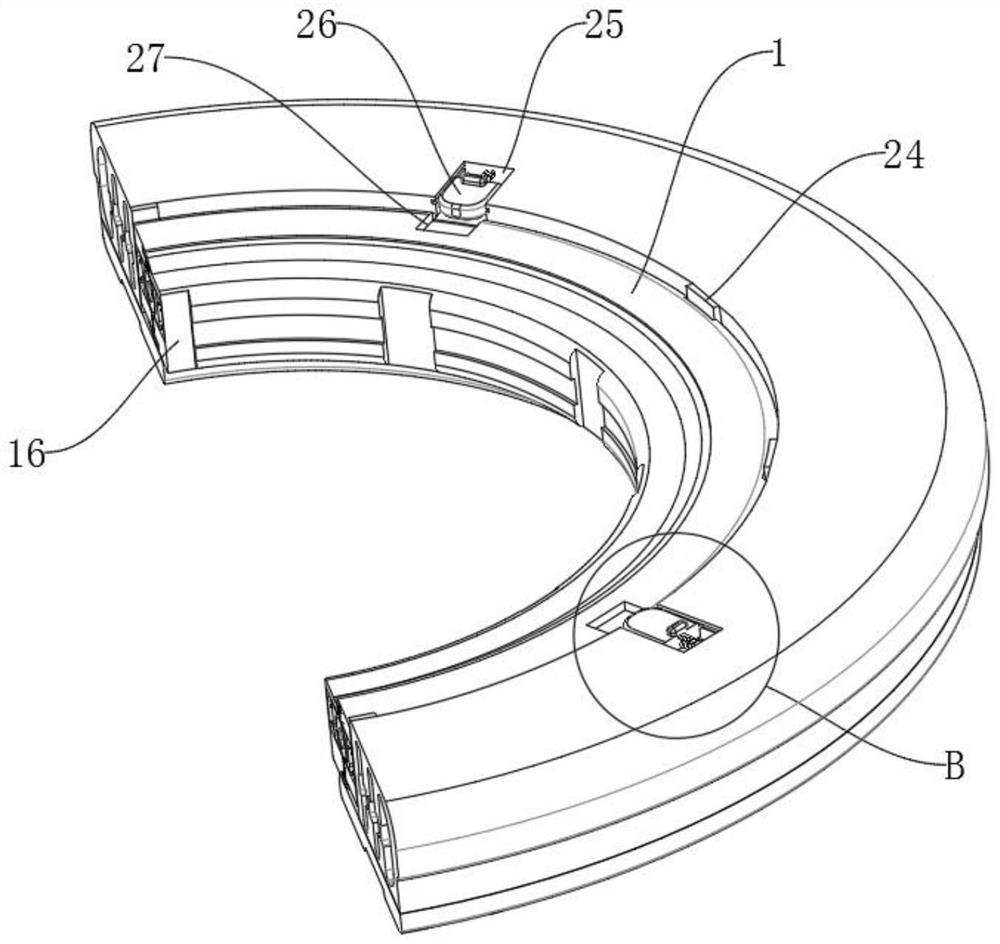

[0034] On the basis of Example 1, please refer to Figure 1-6 As shown, it also includes: the outer surface of the bearing outer ring 1 is covered with a fixing seat 23. The inner bottom surface of the fixing seat 23 fits with the bottom surface of the bearing inner ring 3, and the inner surface of the fixing seat 23 is equidistantly fixed along the circumferential direction. A plurality of limit teeth 24, the top of the fixed seat 23 is equidistantly provided with a plurality of sliding passages 25 along the circumferential direction, the inner walls of both sides of the plurality of sliding passages 25 are provided with rectangular chute 35, a plurality of rectangular chute 35 Rectangular sliders 30 are slidably connected to the inside of each of them. Limiting blocks 26 are fixed between the outer walls of two rectangular sliders 30 inside a plurality of sliding passages 25. The rear surface of the limiting blocks 26 is fixed with a first Spring 29, one end of the first spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com