Short-distance anti-explosion gun inspection system unit

A system unit, short-range technology, applied in weapon accessories, offensive equipment, weapon testing, etc., can solve problems such as the inability to effectively reduce the speed of shrapnel, and the shrapnel is easy to bounce and splash, and achieve the effect of preventing shrapnel from splashing and ejecting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

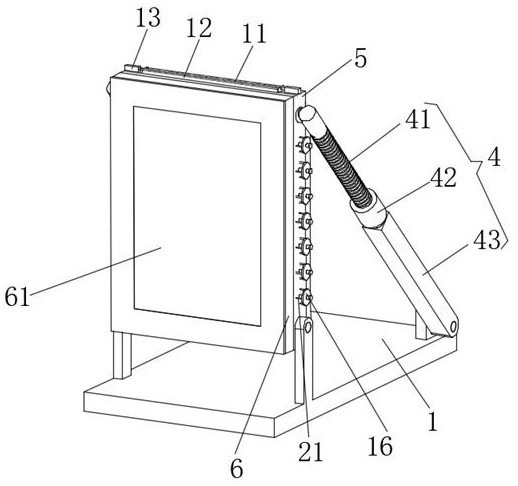

[0030] Embodiment 1: A close-range explosion-proof gun inspection system unit, including a base 1, a deceleration assembly 3 and a support assembly 4;

[0031] Base 1: The middle part of the upper end is rotatably connected with a panel frame 5, and the left and right inner walls of the panel frame 5 are provided with disassembly components 2 at equal intervals, and the inside of the panel frame 5 is uniformly rotated and connected with a steel sheet 7, and the upper ends of the steel sheet 7 extend to the panel frame 5 is provided with a gear 11 on the outer side and at the upper end, and a rack plate 12 is slidably connected inside the dovetail grooves arranged symmetrically on the upper end of the panel frame 5, and the gears 11 are meshed with two rack plates 12, and the middle part of the upper surface of the panel frame 5 A cylinder 13 is symmetrically arranged on the left and right, and the inside of the cylinder 13 is slidingly connected with a piston rod 14. The opposi...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is:

[0037] In this embodiment, the disassembly assembly 2 includes a connecting rod 21, an L-shaped external threaded sleeve 22, a mounting ring 23, a ceramic ball 24, and a mounting groove 25. The mounting groove 25 is evenly arranged on the left and right inner walls of the panel frame 5, and the inside of the mounting groove 25 Ceramic balls 24 are placed on them, and connecting rods 21 are slidably connected in the circular holes evenly arranged at the edge of the mounting groove 25. The inner ends of the connecting rods 21 at the edge of the same mounting groove 25 are all fixedly connected with the mounting ring 23, and the mounting ring The outer surface of 23 is all threaded with L-type external thread sleeve 22, the aperture of mounting ring 23 is greater than the diameter of ceramic ball 24, the minimum diameter of L-type external thread sleeve 22 is less than the diameter of ceramic ball 24, also includes...

Embodiment 3

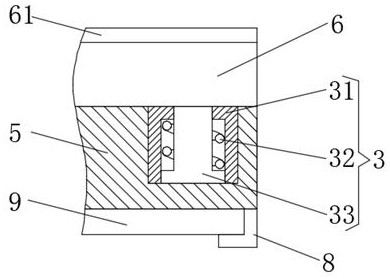

[0040] The difference between this embodiment and Embodiment 1 is:

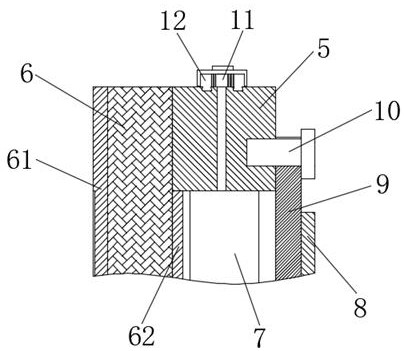

[0041] In this embodiment, the deceleration assembly 3 includes a sleeve 31, a spring 32 and a T-shaped bar 33. The sleeve 31 is evenly arranged on the four corners of the front side of the panel frame 5, and the inside of the sleeve 31 is slidably connected with a T-shaped bar 33, T The middle part of profile bar 33 is all movably socketed with spring 32, and spring 32 is all positioned at the inside of sleeve 31, and the front end of T-shaped bar 33 is all fixedly connected with the back side of composite board 6, and the front side of composite board 6 is provided with There is a deceleration surface 61 , and a reverse deceleration surface 62 is provided on the rear side of the composite plate 6 .

[0042] Specifically, it is arranged in this way that when the ejected bullet contacts the rear side of the reverse deceleration surface 62, the composite plate 6 is moved forward, the T-shaped bar 33 slides for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com