Thin-wall type cooling hole liquid flow detection device and method

A detection device and cooling hole technology, which is applied in the direction of measuring device, measuring fluid pressure, engine testing, etc., can solve the problems of difficult fixing, difficult sealing, high deformation risk, etc., to avoid product deformation and facilitate protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

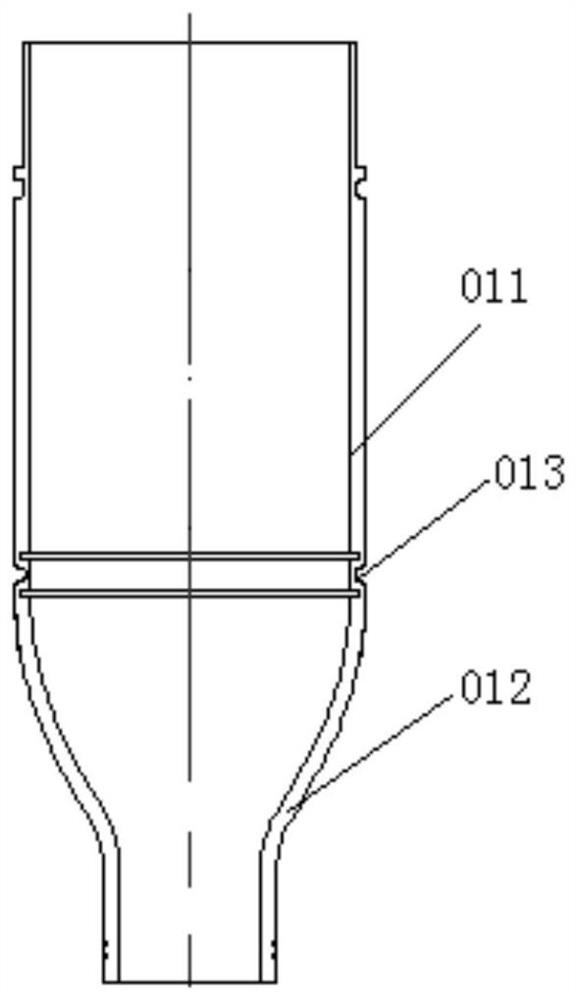

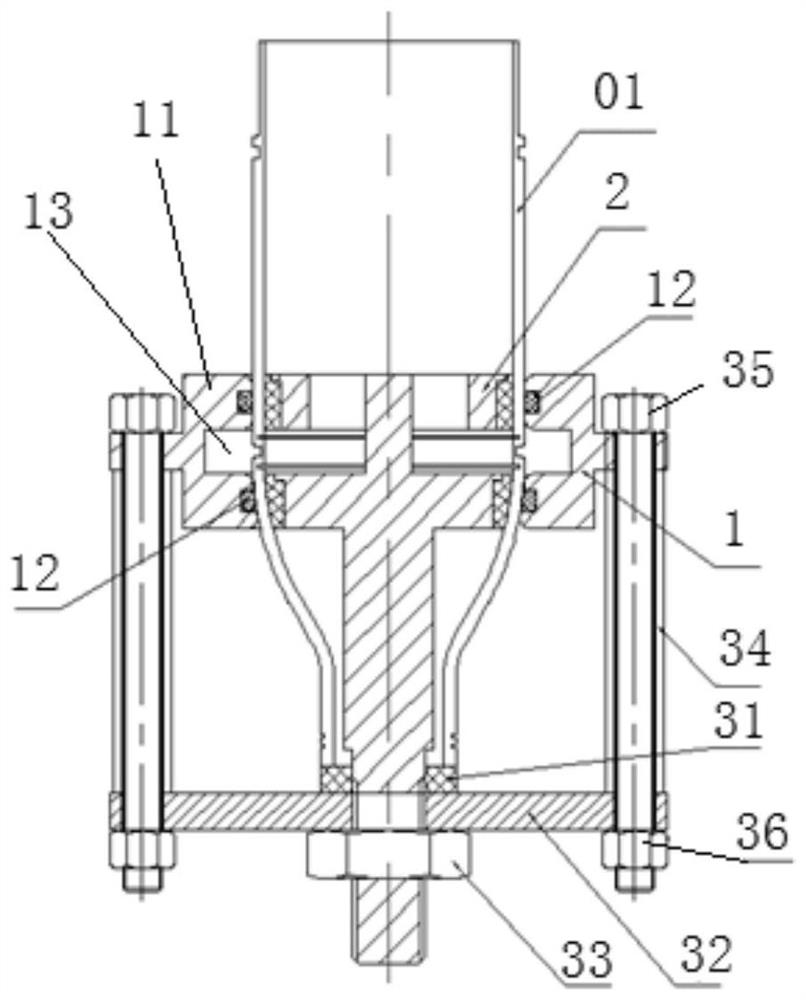

[0059] Such as figure 2 , image 3 and Figure 8 As shown, a thin-wall cooling hole liquid flow detection device of the present invention includes a water inlet assembly 1, an inner tube assembly 2 and a connecting assembly. According to the principle that the action force and the reaction force are equal in magnitude and opposite in direction, the screw rod 35 of the connecting assembly The water inlet assembly 1 and the inner tube assembly 2 are connected as a whole, so that the force exerted by the water inlet assembly 1 and the inner tube assembly 2 on the product 01 to be tested is reversed and offset.

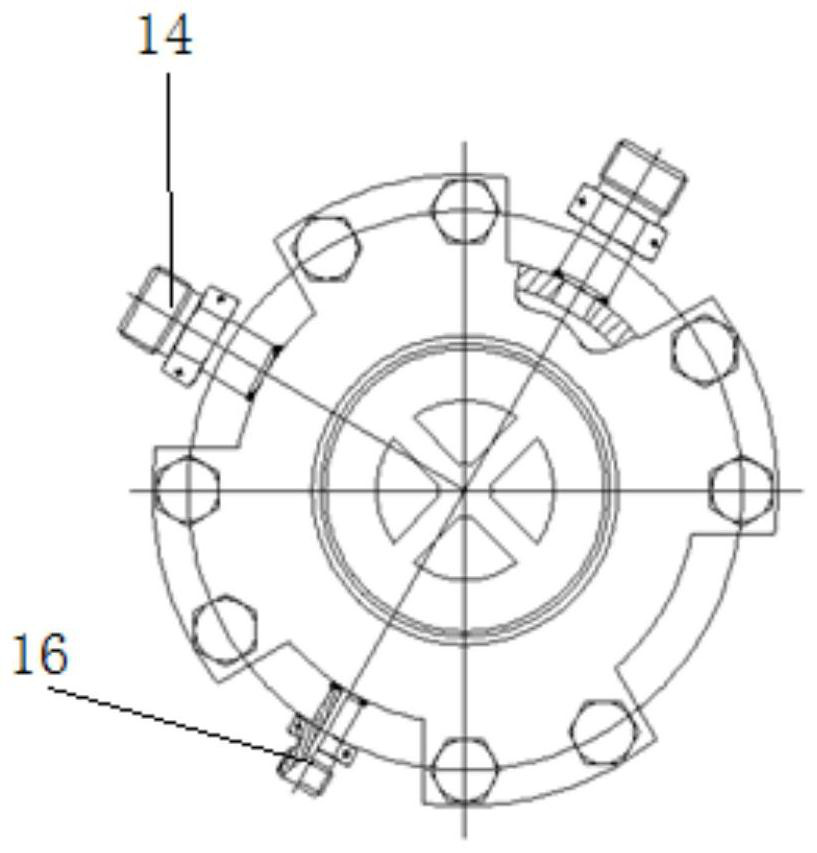

[0060] Such as Figure 4a and Figure 4b As shown, the water inlet assembly 1 includes a water inlet collector 11 and two sealing rings 12. The middle part of the water inlet collector 11 is provided with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com