Method and device for automatically generating crystal grain detection sample

An automatic generation and grain technology, applied in image data processing, instruments, calculations, etc., can solve the problems of large number of samples, inaccurate manual alignment, difficult selection, etc., to achieve the effect of accurate position and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

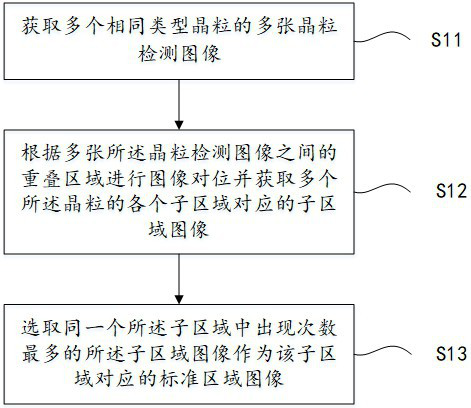

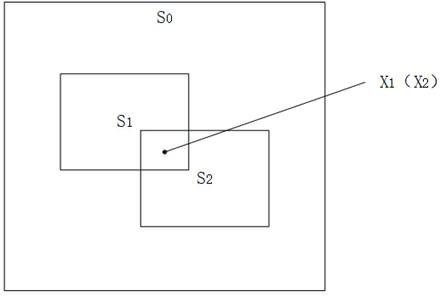

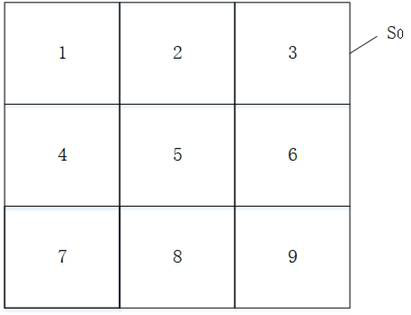

[0042] like figure 1 As shown, the first embodiment of the present invention proposes a method for automatically generating a grain inspection sample, comprising the following steps: Step S11 acquires multiple grain inspection images of a plurality of grains of the same type; Detecting overlapping regions between images, performing image alignment and obtaining sub-region images corresponding to each sub-region of a plurality of said crystal grains; step S13 selecting the sub-region image with the largest number of occurrences in the same sub-region as the sub-region image Standard grain images corresponding to the subregions.

[0043] In step S11, the same type of grain mentioned is the grain with the same appearance characteristics among different individuals. When performing grain defect detection, multiple grains of the same type can be distributed on the same wafer (wafer) , and can also be distributed on different wafers. For example, a camera or other equipment is use...

no. 2 example

[0054] like Figure 4 As shown, the second embodiment of the present invention proposes an automatic generation device 20 for grain inspection samples, including, for example, a grain inspection image acquisition module 201 , a sub-region image acquisition module 202 , and a standard grain image selection module 203 .

[0055] Wherein, the grain detection image acquisition module 201 is used to acquire multiple grain detection images of multiple grains of the same type. The sub-region image acquisition module 202 is configured to perform image alignment according to overlapping regions among the multiple inspection images of the crystal grains and acquire sub-region images corresponding to each sub-region of the multiple crystal grains. The standard grain image selection module 203 is used to select the sub-region image that appears most frequently in the same sub-region as the standard grain image corresponding to the sub-region.

[0056] Further, such as Figure 5 As shown...

no. 3 example

[0061] like Figure 8 As shown, the third embodiment of the present invention proposes an automatic generation system 30 for grain inspection samples, for example including: a memory 32 and one or more processors 31 connected to the memory 32 . The memory 32 stores a computer program, and the processor 31 is used to execute the computer program to realize the method for automatically generating a grain inspection sample as described in the first embodiment. For the specific automatic generation method of grain detection samples, please refer to the method described in the first embodiment, which will not be repeated here for the sake of brevity, and the beneficial effect of the automatic generation system 30 for grain detection samples provided by this embodiment is the same as that of the first embodiment The beneficial effects of the provided method for automatically generating grain inspection samples are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com