Chip packaging structure integrated with passive element and packaging method

A chip packaging structure and passive component technology, applied in electrical components, electric solid state devices, semiconductor devices, etc., can solve the problems of low integration and large thickness of semiconductor packaging components, and achieve improved heat dissipation performance, high stability, and reliable coupling. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

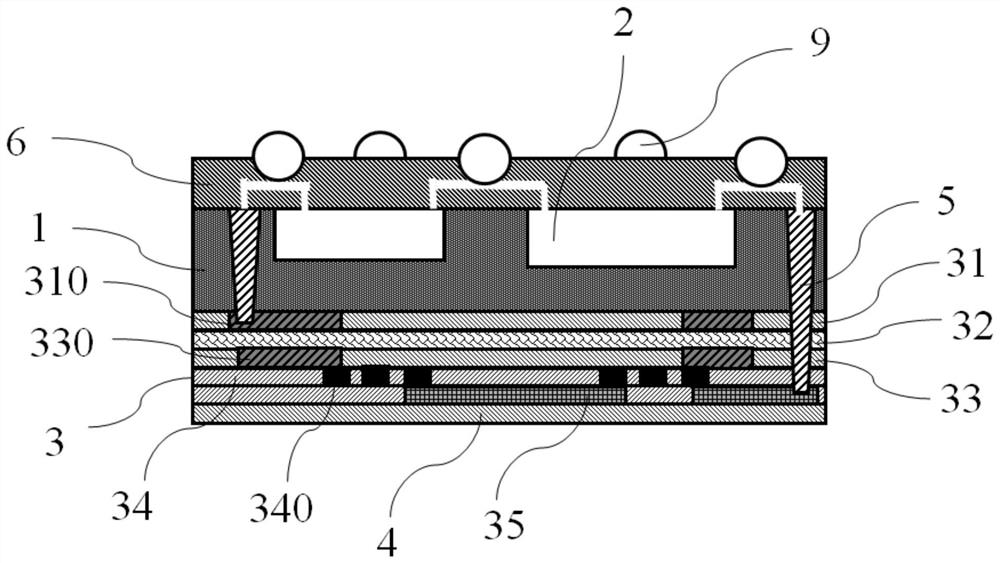

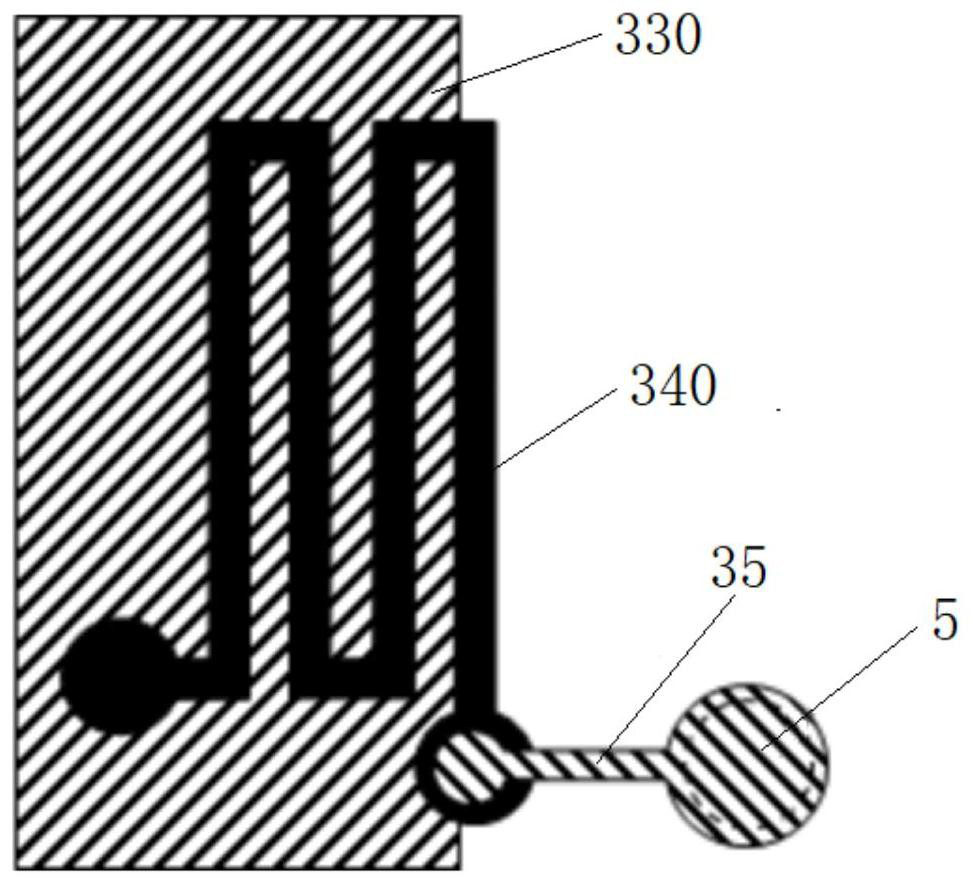

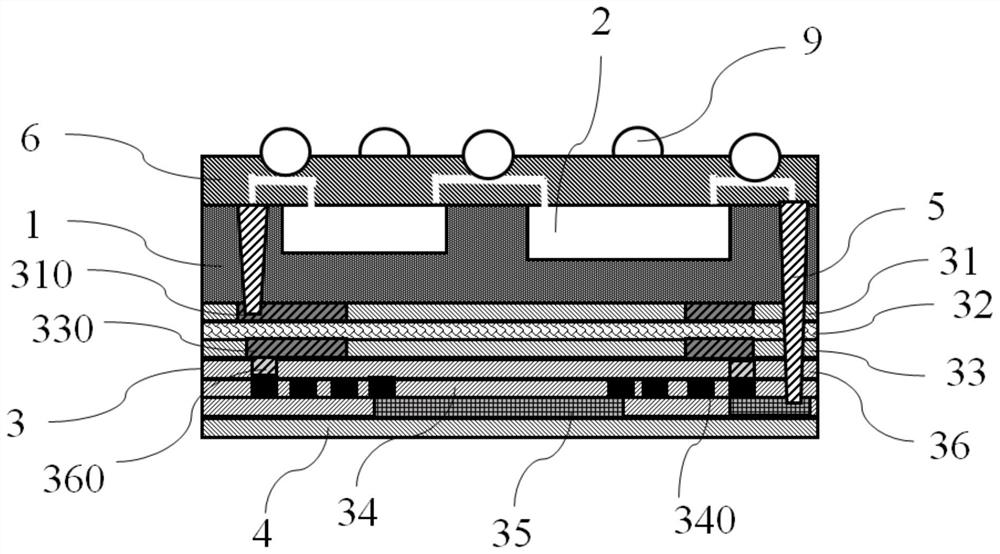

[0037] The embodiment of the present invention improves a chip package structure integrating passive components, such as figure 1 As shown, it includes: a package body 1 with a chip 2 packaged inside; the device surface of the chip 2 is located on the same plane as the first surface of the package body 1; the passive element layer 3 is arranged on the second surface of the package body 1; the first insulating Layer 4 is arranged on the passive element layer 3; the conductive column 5 is arranged in the package body 1, one end of the conductive column 5 is coupled with the passive element layer 3, and the other end is located on the same plane as the first surface of the package body 1; The wiring layer 6 is disposed on the first surface of the package body 1 and coupled with the chip 2 and the conductive pillar 5 . In this embodiment, the device surface of the chip 2 refers to the plane where the pads of the chip 2 are located, and the device surface of the chip 2 is located o...

Embodiment 2

[0052] This embodiment provides a chip packaging method for integrating passive components, such as Figure 5 shown, including the following steps:

[0053] Step S1: providing a substrate, and forming an adhesive layer on the substrate. Such as Figure 6 As shown, in a specific embodiment, the material of the substrate 7 can be glass or ceramics, etc., and the material of the adhesive layer 8 can be thermal release adhesive or UV adhesive film, etc. In a specific embodiment, spray coating, spin coating or film sticking can be used and so on to form the adhesive layer 8 on the substrate 7 .

[0054] Step S2: Paste the device surface of the chip on the pasting layer. Such as Figure 7 As shown, in this embodiment, the device surface of the chip 2 refers to the plane where the pads of the chip 2 are located. In a specific embodiment, there may be one or more chips 2, and the number of chips 2 is determined according to the needs of actual application scenarios.

[0055] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com