Power phase controller based on single-chip microcomputer

A technology of phase controller and single-chip microcomputer, which is applied in electrical components, structural parts of electrical equipment, chassis/cabinet/drawer parts, etc., can solve the problems of high surface temperature and easy shaking of the phase controller. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

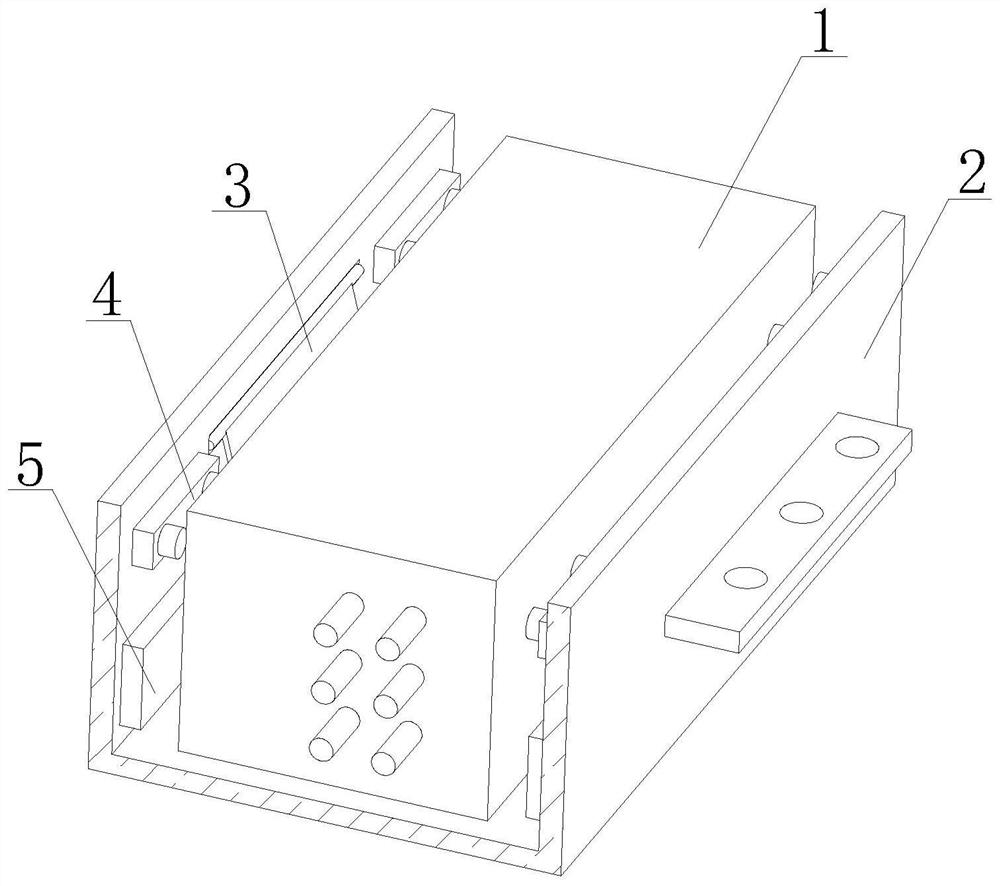

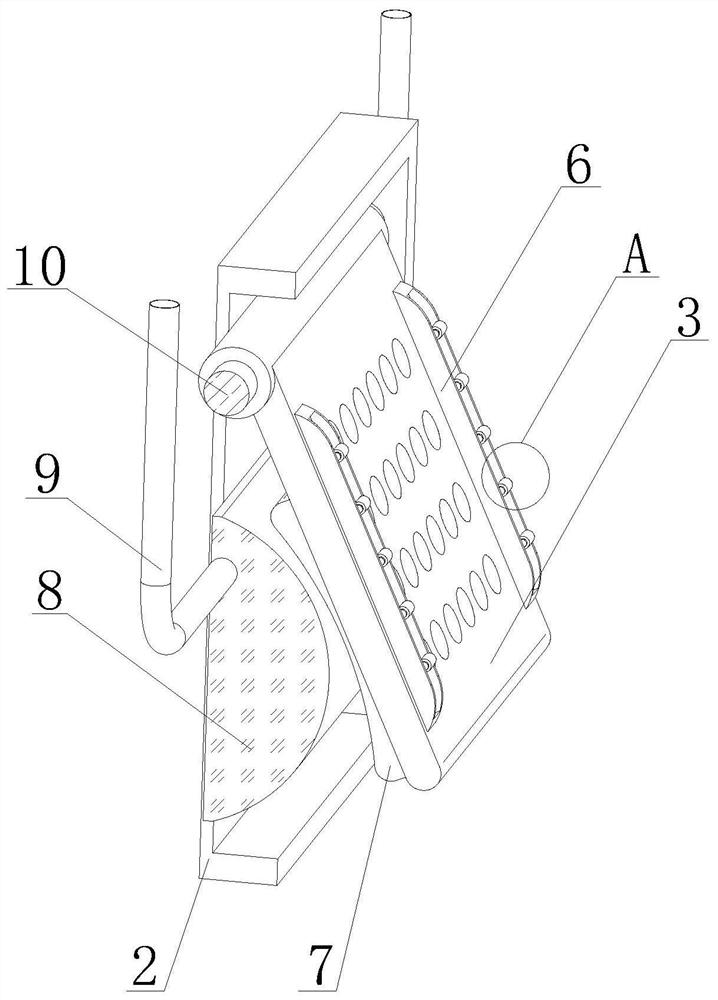

Embodiment 1

[0039] Such as Figure 1-7 As shown, the present invention provides a phase controller body 1 and a mounting bracket 2, the outer wall of the phase controller body 1 is engaged with the inner side wall of the mounting bracket 2, and the inner side wall of the mounting bracket 2 is fixedly installed with an extrusion pre-set. A tightening device 3, one side of the extrusion pretensioning device 3 is provided with a pressure contact device 4, one end of the pressure contact device 4 is fixedly connected with the inner side wall of the installation card seat 2, and a stabilizing device is provided under the pressure contact device 4 5. The upper left end of the extruding pretensioning device 3 is rotatably connected with a connecting shaft 10, so that the extruding pretensioning device 3 can rotate along the connecting shaft 10, and one end of the connecting shaft 10 is fixedly connected with the inner side wall of the mounting bracket 2, The left side of the extrusion pre-tighte...

Embodiment 2

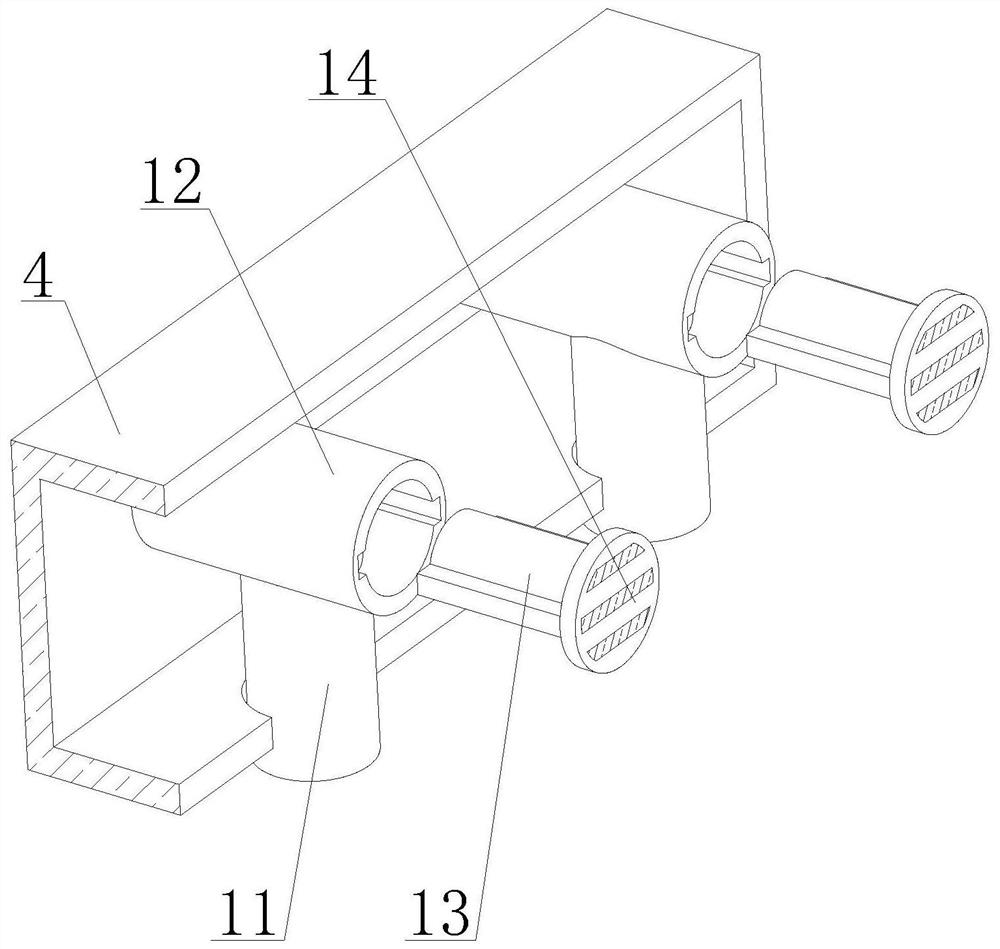

[0041] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner wall of the pressure contact device 4 is fixedly installed with a sealing cavity 12, and the inner wall of the sealing cavity 12 is slidably connected with a sealing push block 13, The outer wall of the sealing pushing block 13 runs through the inner wall of the pressure contact device 4, and the right side of the sealing pushing block 13 is fixedly installed with a contact snap ring 14, and the bottom of the sealing cavity 12 is fixedly installed with a flow pipe 11, and the sealing pushing block 13 can slide back and forth in the sealed chamber 12, and the flow pipe 11 can guide the gas in the gas guide pipe 9 into the sealed chamber 12, the outer wall of the flow pipe 11 is engaged with the inner wall of the pressure contact device 4, and the flow pipe 11 The inner wall of the gas guide tube 9 is fixedly connected, and the gas guide t...

Embodiment 3

[0043] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer wall of the auxiliary sliding bar 6 is provided with a groove, and the inside of the groove is fixedly installed with a rotating shaft 15, and the outer wall of the rotating shaft 15 is rotatably connected There is a sleeve 16, and the sleeve 16 can rotate along the rotating shaft 15, thereby facilitating the sliding of the phase controller body 1 on the extruding pretensioning device 3. The inner wall of the extruding pretensioning device 3 is provided with a heat dissipation assembly 17, and the heat dissipation assembly The bottom of 17 is fixedly connected with the bottom of the inner wall of the extruding pretensioning device 3. A diffuser tube 18 is arranged above the cooling assembly 17. During operation, the fluidity of the gas inside the extrusion pretensioning device 3 can be changed, and the gas flow can be diverted outward th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com