Sugar-reduced fruit juice and preparation method thereof

A technology for fruit juice and equipment, which is applied in the field of sugar-reduced fruit juice and its preparation, and can solve the problems of high sugar content and unfavorable health of consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] like figure 1 Shown, the preparation method of the reduced-sugar fruit juice provided by the invention comprises the following steps:

[0033] Step S1, thawing the frozen squeezed juice cubes.

[0034] The juice is made by freshly squeezed natural fruit without adding any preservatives or ingredients. After being squeezed into juice, it is stored under freezing conditions below -18°C. The transportation process is also carried out through the cold chain. controlled within 2°C. Juice types include but not limited to grape juice, mango juice, orange juice, pear juice. The fruit juice after arrival needs to be thawed before membrane treatment.

[0035] Generally, the natural thawing method can be used, and the unopened sealed fruit juice is placed in a cool place to thaw at room temperature, but the room temperature should not exceed 30°C, and placed for 3-8 hours until the ice cubes are completely melted.

[0036] When thawing naturally, the melting of ice crystals in...

Embodiment 1

[0052] Thaw the grape juice, and then use a 200-mesh filter bag to filter the juice. The filtration process is carried out at room temperature. After filtration, no precipitated fruit particles and other physical foreign matter remain; the filtered grape juice is ultra-filtered to remove solids at room temperature. The pore size of the ultrafiltration membrane core is 60nm, the control pressure is 1.2MPa during the operation, and the operation time is 3.5h. When the temperature of the material rises to more than 25 degrees Celsius due to the pressure increase, the cooling circulating water is started to control the grape juice material below 25 degrees Celsius.

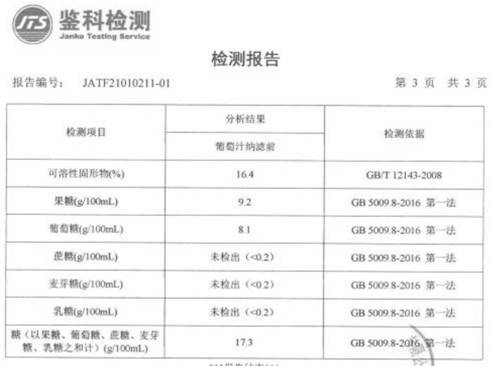

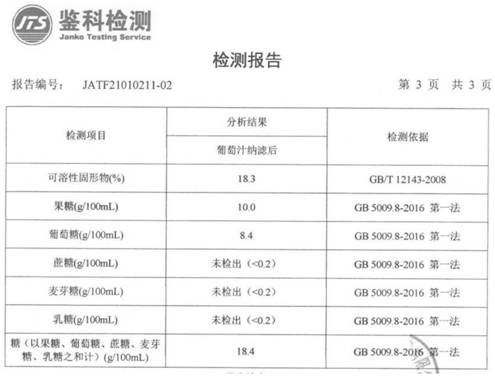

[0053] The grape juice after ultrafiltration and solid removal was sent as a sample for sugar detection.

[0054] Take 40L of grape juice after ultrafiltration and solid removal treatment and pour it into the circulation tank of the nanofiltration equipment. The nanofiltration equipment is equipped with a membrane core...

Embodiment 2

[0058] Take the apple juice to thaw, and then use a 250-mesh filter bag to filter the juice. The filtration process is carried out at room temperature. After filtration, no precipitated fruit particles and other physical foreign matter remain; the filtered apple juice is ultra-filtered to remove solids at room temperature. The pore size of the ultrafiltration membrane core is 70nm, the control pressure is 1.0MPa during the operation, and the operation time is 3 hours. When the temperature of the material rises to more than 25 degrees Celsius due to the pressure increase, the cooling circulating water is started to control the apple juice material below 25 degrees Celsius.

[0059] The apple juice after ultrafiltration and solid removal was sent as a sample for sugar detection.

[0060] Take 40L of apple juice after ultrafiltration and solid removal treatment and pour it into the circulation tank of the nanofiltration equipment. The nanofiltration equipment is equipped with a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com