A foam high-altitude fire extinguishing system

A fire extinguishing system and foam fire extinguishing technology, applied in fire rescue, etc., can solve problems such as inability to work for a long time, poor effect, low foam mixing efficiency, etc., to reduce smoke concentration and harmful particles, increase heat dissipation effect, and improve continuous work effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

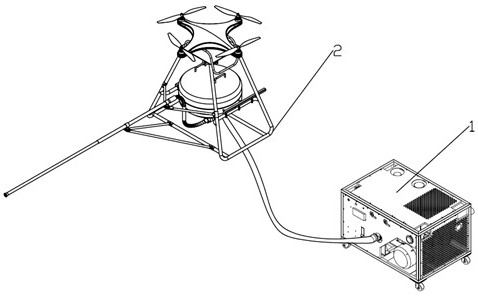

[0049] like figure 1 , figure 2 As shown, a foam high-altitude fire-extinguishing system includes an aircraft fire-extinguishing device 2 and a foam fire-extinguishing device 1; wherein, the aircraft fire-extinguishing device 2 and the foam fire-extinguishing device 1 are connected by a hose;

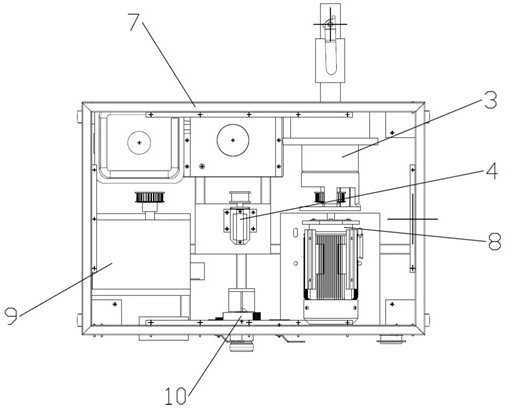

[0050] The foam fire extinguishing device 1 includes an installation box 7, a primary mixing device 3, a driving device 8, an air compressor 9, a secondary mixing device 10 and a radiator 4; the primary mixing device 3 is used to provide foam liquid for the foam extinguishing device 1; drive The device 8 is used to provide power for the primary mixing device 3 and deliver the mixed foam liquid to the secondary mixing device 10; the air compressor 9 is used to provide compressed air for the secondary mixing; the secondary mixing device 10 is used to mix the foam liquid and compressed air, and transport the mixed compressed foam liquid to the aircraft fire extinguishing device 2 through...

Embodiment 2

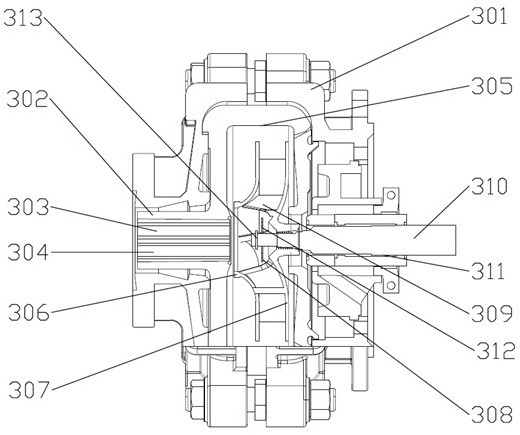

[0055] This embodiment is a further refinement of the first embodiment. like image 3 As shown, the primary mixing device 3 includes a device body 301, and a liquid mixing device is arranged inside the device body 301, and the liquid mixing device is used to mix water and foam liquid; The interior of the liquid pipe 302 includes a water inlet pipe 303 and a foam inlet pipe 304; a liquid outlet 305 is provided on the upper end of the device body 301, and the liquid outlet 305 is used to discharge the mixed foam liquid;

[0056] The liquid mixing device includes a front cover 306 and a rear cover 307, the front cover 306 and the rear cover 307 cooperate to form a centrifugal cavity, and a stirring blade 308 and a centrifugal blade 309 are arranged inside the centrifugal cavity; wherein, the centrifugal blades 309 are uniform It is arranged on the inner wall of the rear cover plate 307 , and the stirring blade 308 is arranged on the inner side of the centrifugal blade 309 .

[...

Embodiment 3

[0060] This embodiment is a further refinement of the first embodiment. like Figure 4 As shown, a cooling water inlet 401 is arranged at the upper end of the radiator 4, and a water blocking plate is arranged inside the radiator 4; the water blocking plate includes a first water blocking plate 402 and a second water blocking plate 403, wherein, One end of the first water blocking plate 402 is fixedly connected with the inner wall of the casing of the radiator 4, and the other end is inclined downward. The water blocking plate 402 and the second water blocking plate 403 are staggered up and down;

[0061] Inside the radiator 4, a spiral coil 404 is arranged. The spiral coil 404 includes an input end 405 and an output end 406. The input end 405 of the spiral coil 404 is connected to the output end of the cooling oil of the air compressor 9. The spiral coil 404 The output end 406 of the air compressor is connected to the input end of the cooling oil of the air compressor 9 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com