Surface treatment device for powder modification

A surface treatment device and powder modification technology, which is applied in the field of surface treatment devices for powder modification, can solve the problems of nozzle blockage, powder hardening, affecting activation effect, etc., and achieve the effect of avoiding hardening and comprehensive modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

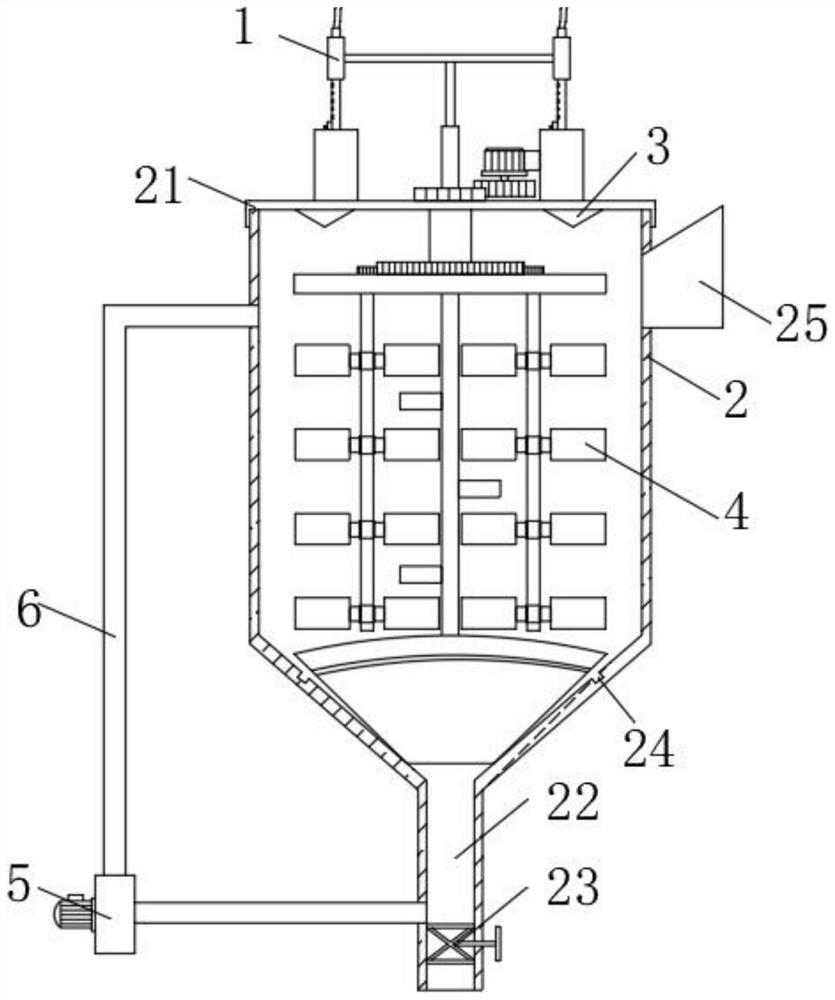

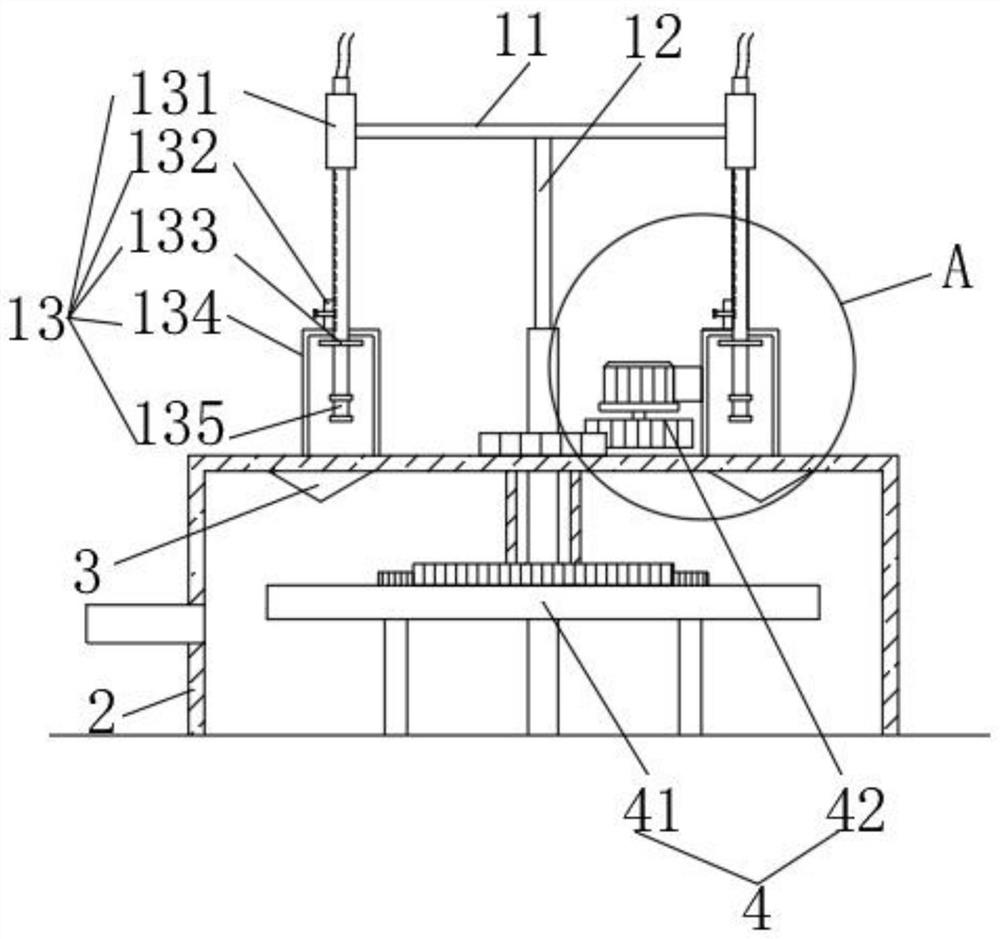

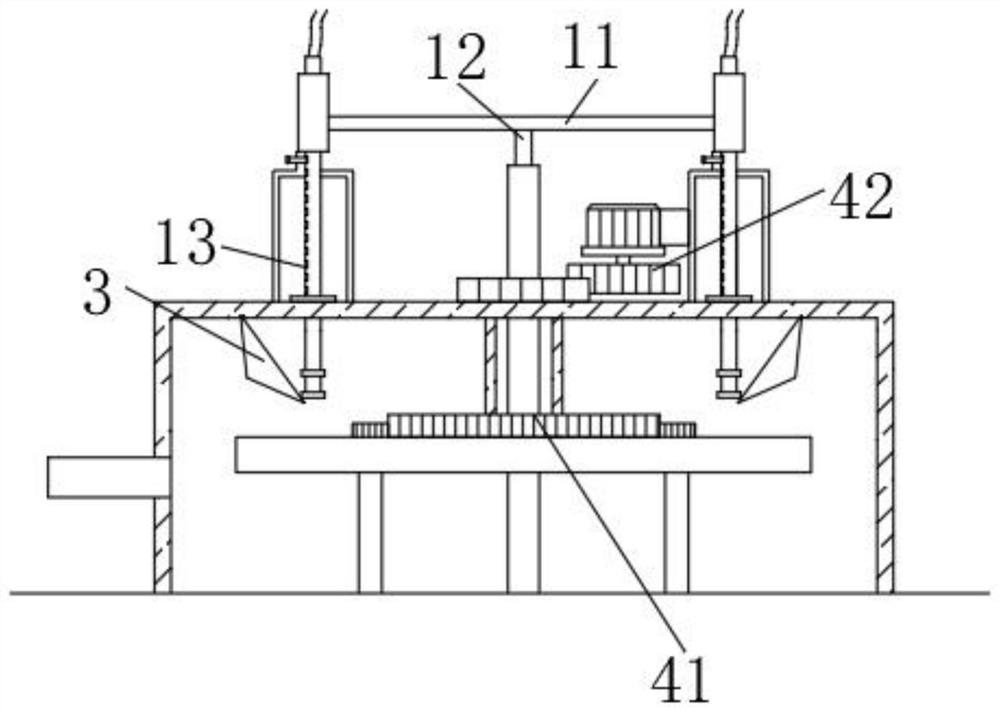

[0029] A surface treatment device for powder modification, figure 1 shows a schematic diagram of the overall structure of the embodiment of the present invention, for example, as figure 1 As shown, it includes a treatment tank 2, the top of the treatment tank 2 is provided with a spraying mechanism 1, and the spraying mechanism 1 is connected to the top of the treatment tank 2 in a lift type; the inner top of the treatment tank 2 is connected by a torsion spring Protective cover 3, the spraying mechanism 1 is used to press down to open the protective cover 3 to add medicine in the treatment tank 2; when the spraying mechanism 1 is not spraying, the spraying mechanism 1 is in the The top of the treatment tank 2, at this time, the protective cover plate 3 seals the opening at the top of the treatment tank 2; to prevent the powder from clogging the spraying mechanism 1 when the inside of the treatment tank 2 is stirred; when spraying, the spraying as shown The mechanism presses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com