Catalyst regeneration scorching method and device

A technology for catalysts and catalyst beds, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems affecting catalyst life and hydrothermal stability of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the technical solutions and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below.

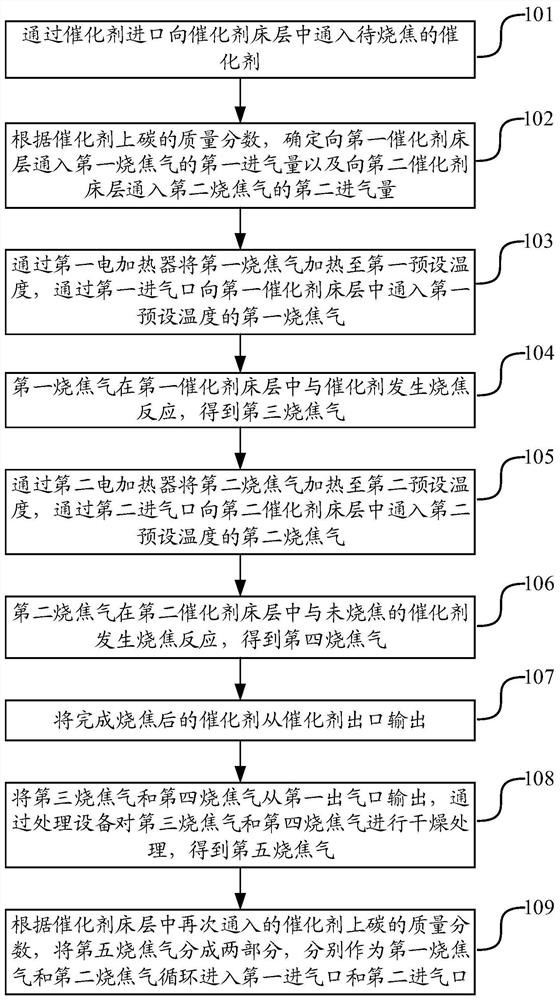

[0066] The embodiment of the present application provides a catalyst regeneration coking method, see figure 1 , the method includes:

[0067] Step 101: Pass the catalyst to be burnt into the catalyst bed through the catalyst inlet.

[0068] The catalyst to be burnt is the catalyst with coke on the surface, the catalyst is located in the catalyst bed, and the catalyst in the catalyst bed moves down slowly by its own gravity.

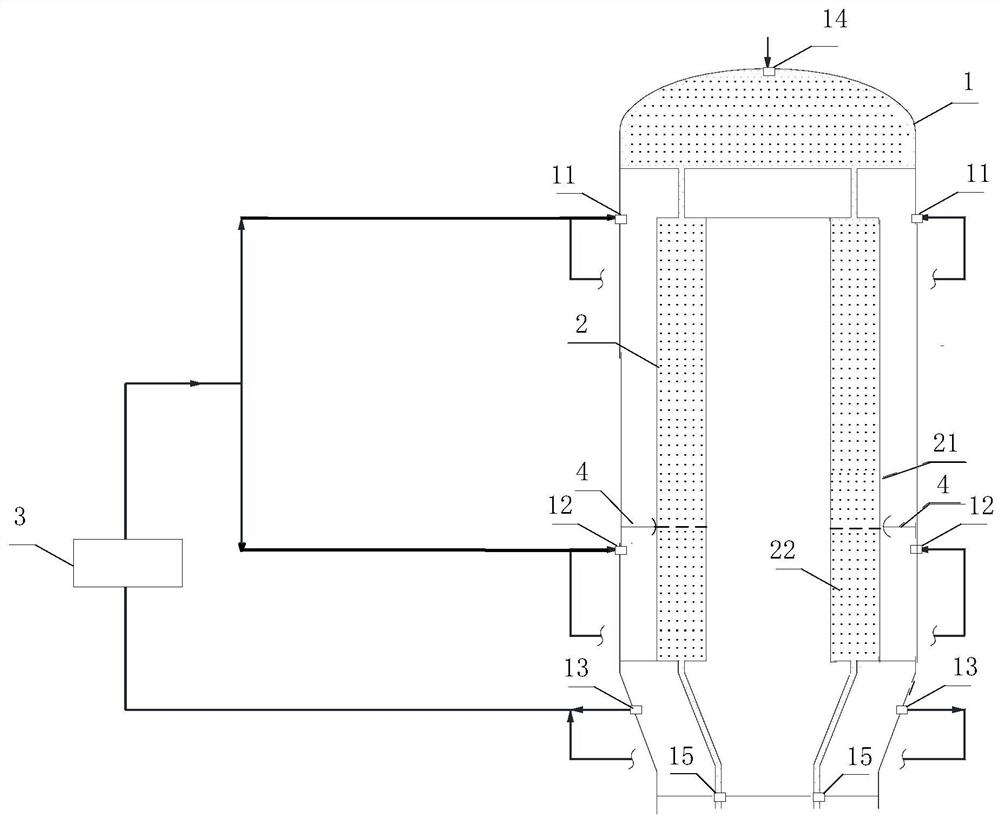

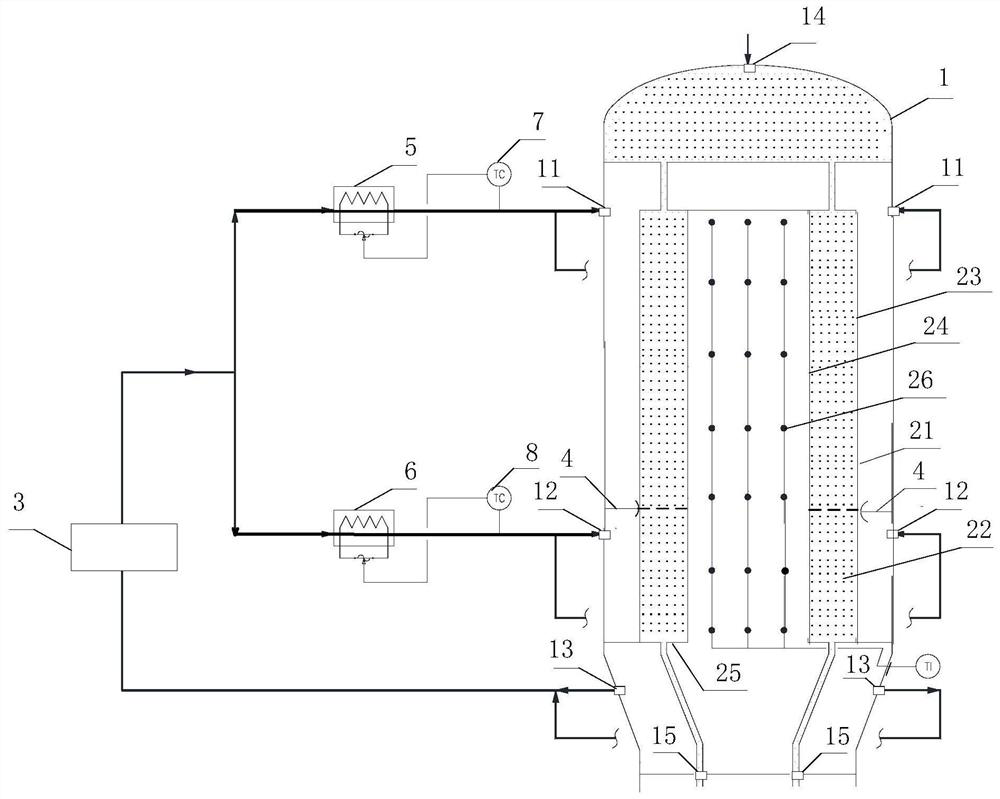

[0069] The catalyst bed includes a first catalyst bed and a second catalyst bed, which are continuous catalyst beds. And the catalyst bed layer is a radial moving bed, including a gas distribution pipe, a gas collection pipe and a supporting bed, an annular chamber is formed between the gas distribution pipe and the gas collection pipe, and the catalyst is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com