Glue extruding device for circuit installation box of solar photovoltaic panel

A solar photovoltaic panel and installation box technology, applied in the field of solar energy, can solve problems such as leakage of glue from the circuit box, affecting the yield rate, and poor installation of the circuit box, so as to achieve the effect of smooth air pipe and avoid trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

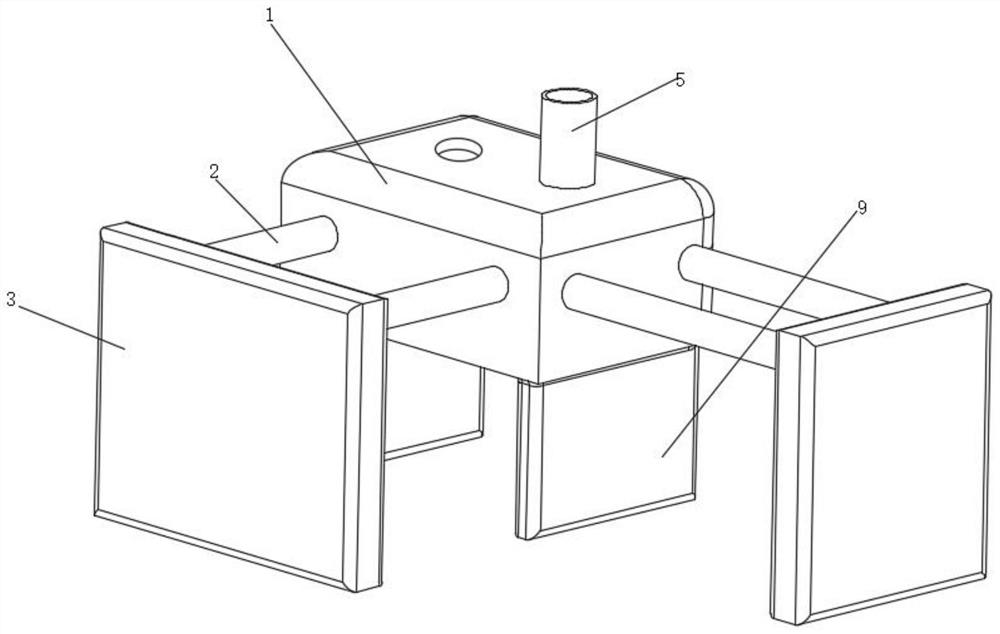

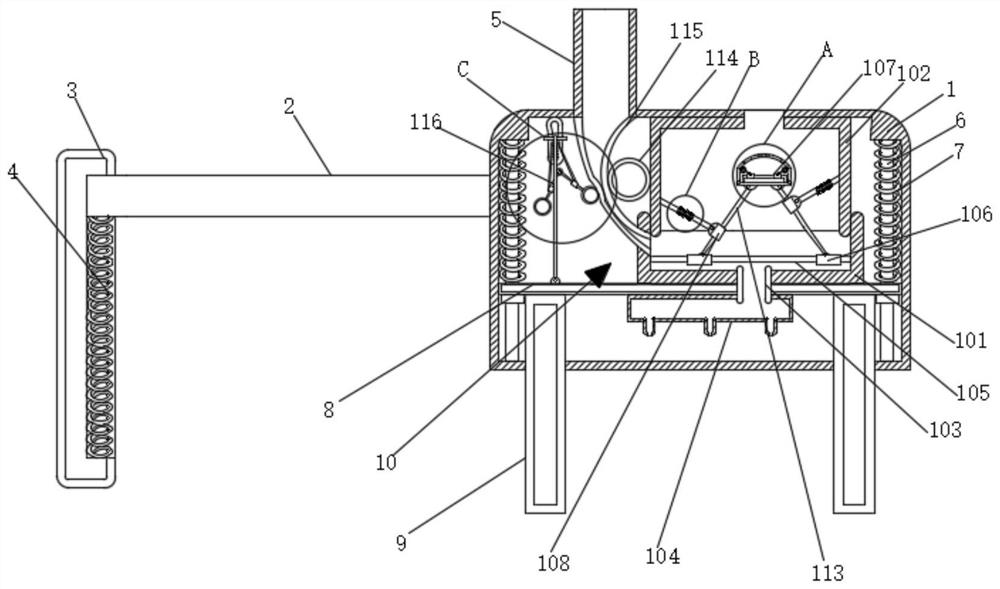

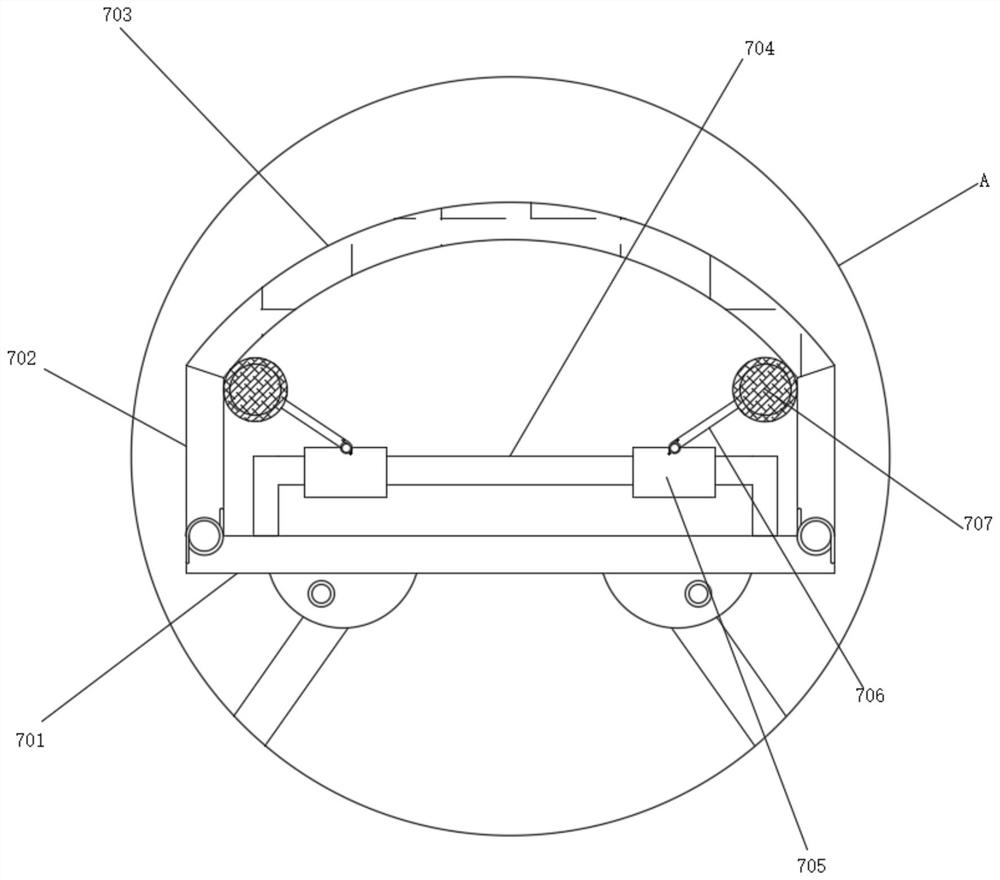

[0022] like Figure 1-6 As shown, the present invention provides a technical solution: a rubber extruding device for a solar photovoltaic panel circuit installation box, including a fixed box 1, the lower side of the fixed box 1 is provided with an opening, and the left side of the fixed box 1 is fixedly connected with a fixed rod 2. The left side of the fixed rod 2 is clamped with the limit plate 3, the first spring 4 is arranged between the bottom of the inner wall of the limit plate 3 and the lower surface of the fixed rod 2, and the upper side of the fixed box 1 is provided with a feed pipe 5 , the lower end of the feed pipe 5 communicates with the upper side of the fixed box 1, and the inside of the fixed box 1 is provided with a fixed column 6. The right side is fixedly connected, the outer wall of the fixed column 6 is sleeved with a second spring 7, the lower end of the second spring 7 is fixedly connected with a fixed plate 8, and the upper end of the second spring 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com