Clamping fixture for milling key grooves in two ends of crankshaft

A technology for milling keyway and crankshaft, applied in the field of crankshaft processing, can solve the problems of high labor intensity, poor quality of keyway, and inability to satisfy the position accuracy of keyway well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

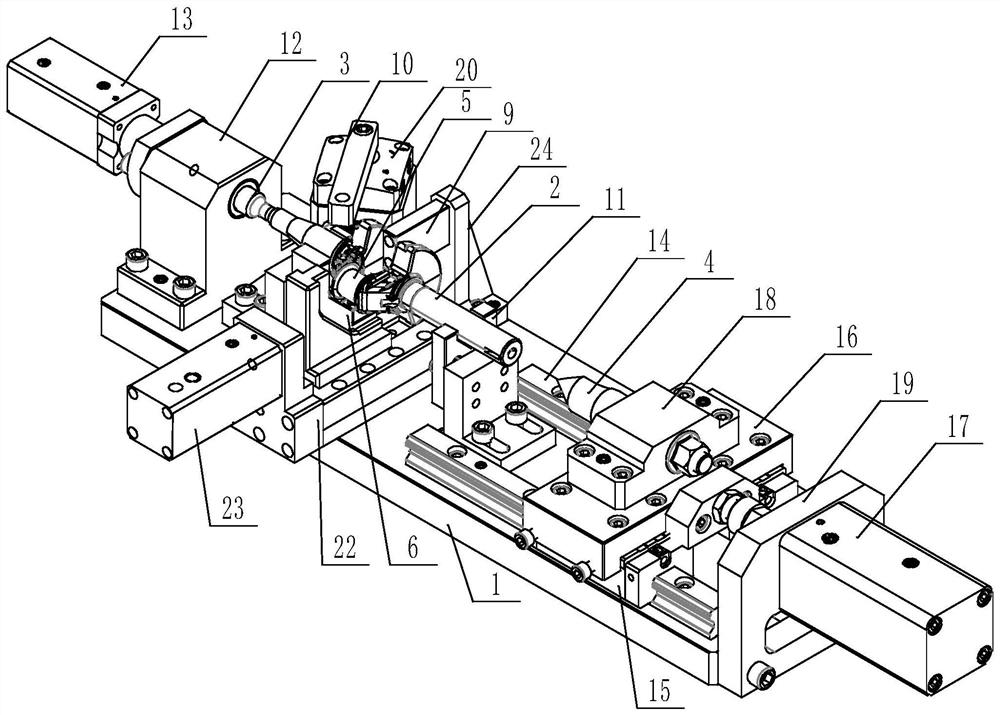

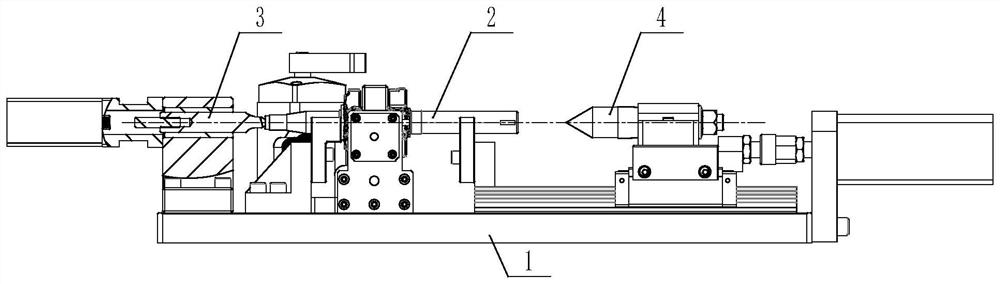

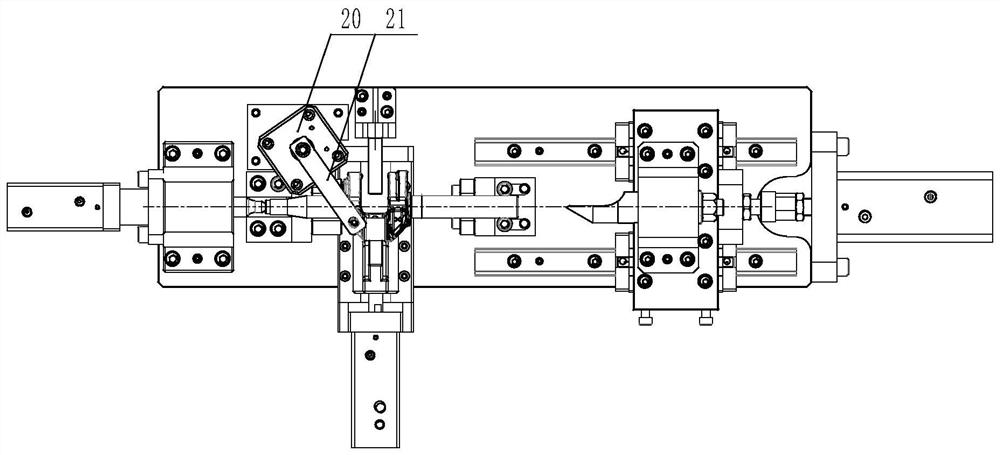

[0032] see Figure 1 to Figure 4 Shown: a clamping fixture for milling keyways at both ends of a crankshaft, including a horizontal bottom plate 1, a support structure is provided on the bottom plate, the support structure has two V-shaped support surfaces spaced along the longitudinal direction of the bottom plate, and the two ends of the crankshaft 2 to be processed are Can respectively overlap and rest on two V-shaped support surfaces; On the outer sides of the two ends of the crankshaft to be detected on the base plate, a positioning top device and a tight top device are respectively provided; the positioning top device includes a horizontal positioning top 3, a positioning top The tip can be abutted in the center hole at one end of the crankshaft to limit the axial position of the crankshaft; the abutment tip device includes abutment tip 4, and a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com