Angle pin pull rod height grinding jig

An oblique pin pull rod and height technology, which is applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve problems such as low efficiency, and achieve the effect of simple clamping operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

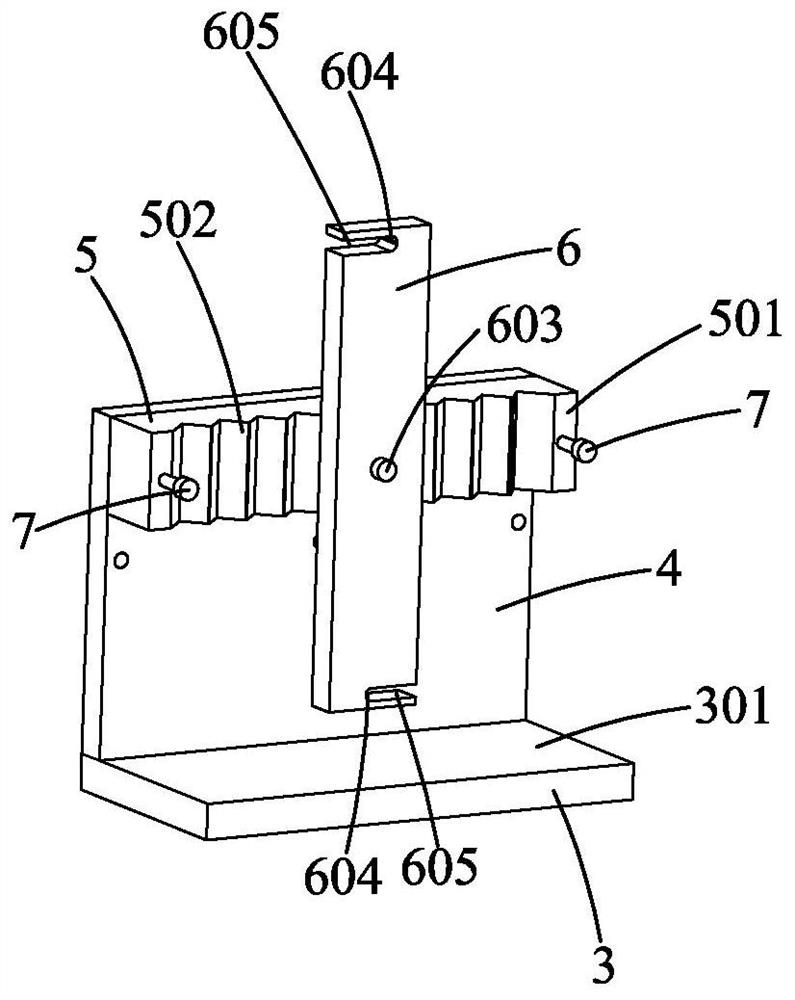

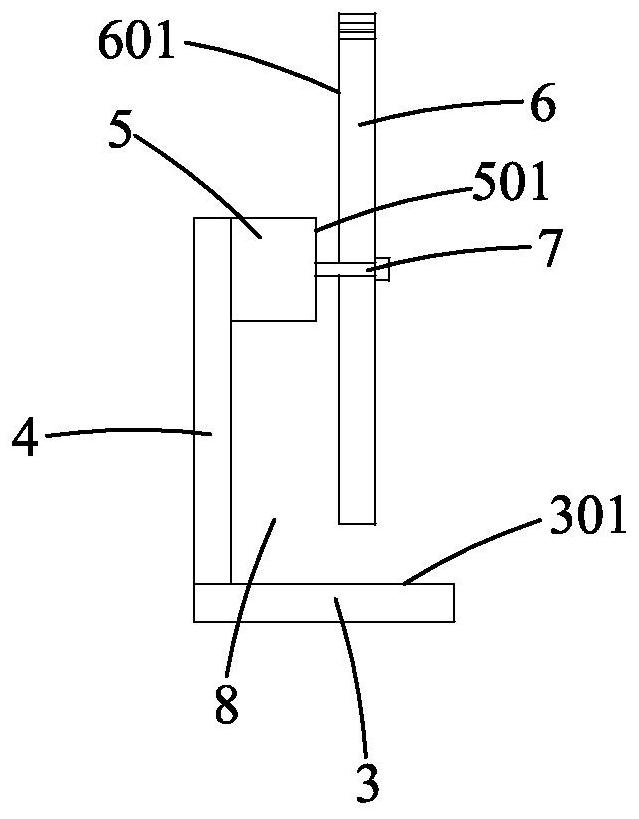

[0037] Such as Figure 2-4 As shown, the present invention provides a kind of oblique pin rod height grinding jig, comprising:

[0038] Body, pressing plate 6 and locking structure.

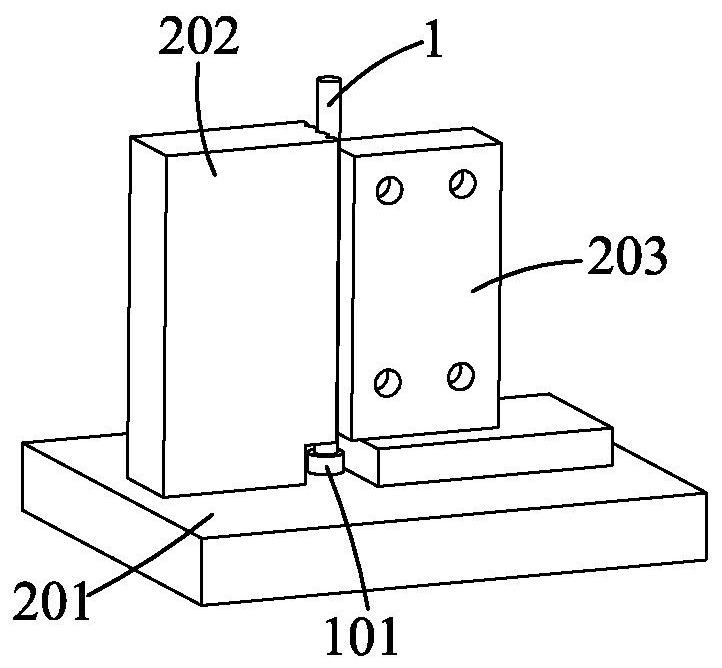

[0039] see figure 2 with image 3 , figure 2 A schematic structural view of a high-grinding jig for oblique pin rods according to the present invention is shown, image 3 A side view of a high grinding jig for oblique pin tie rods of the present invention is shown. The body has a first plane 301 and a second plane 501 perpendicular to the first plane 301 . The second plane 501 is recessed to form a plurality of limiting grooves 502 , and the limiting grooves 502 are all perpendicular to the first plane 301 . The body also has an accommodation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com