Crushing and separating equipment for waste plastic regeneration and crushing and separating method of crushing and separating equipment

A technology for waste plastics and separation equipment, applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of general crushing effect and pollution, and achieve the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

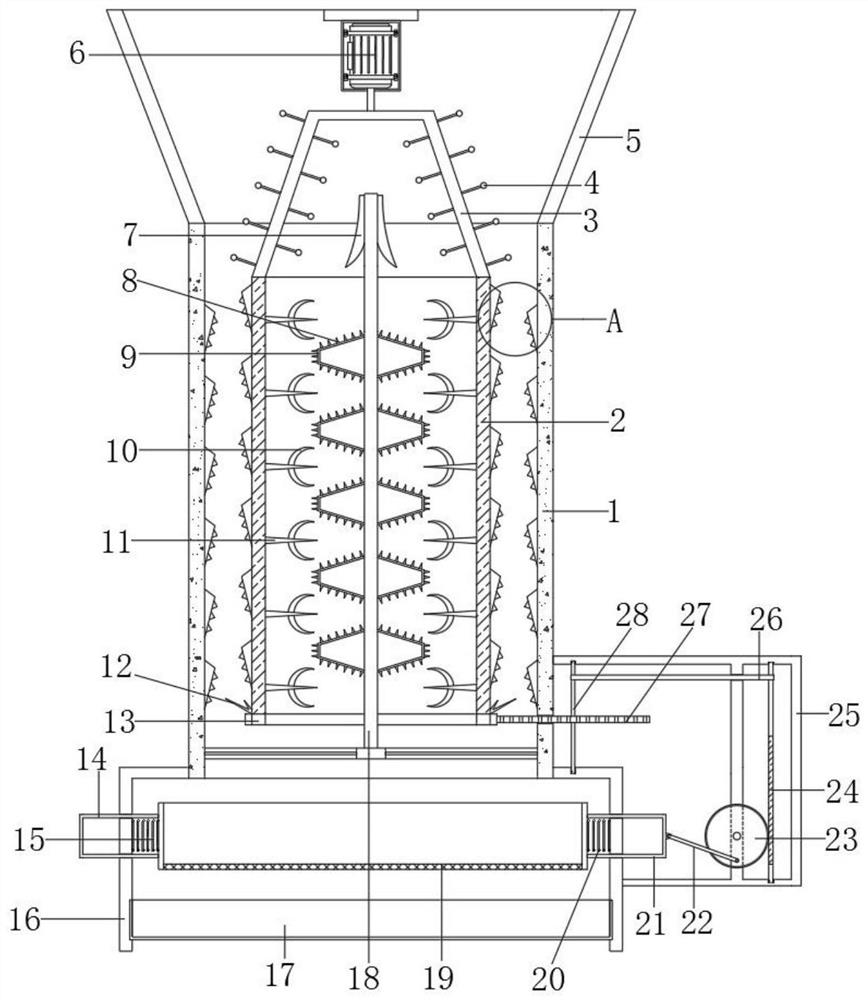

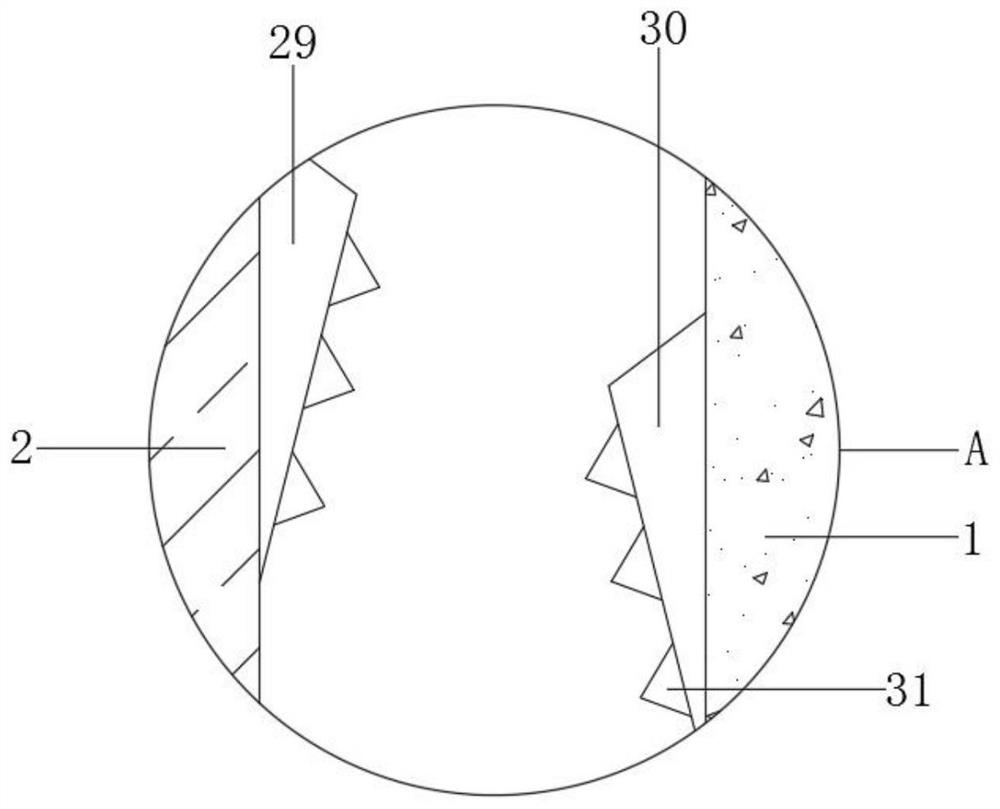

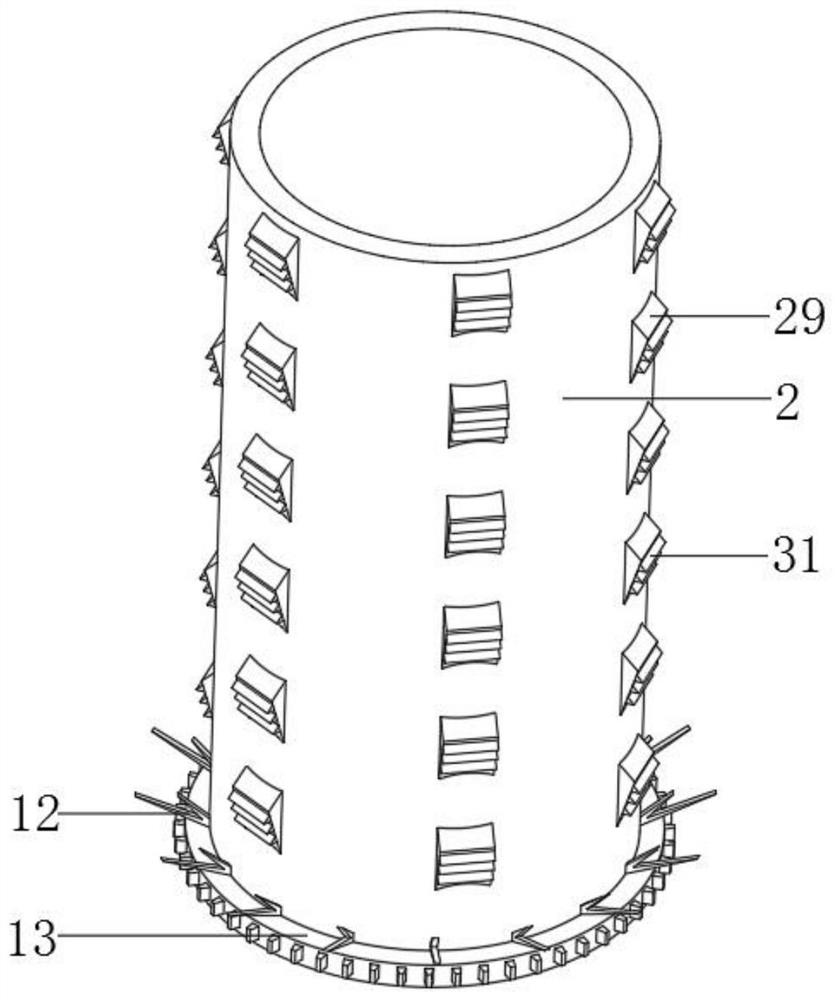

[0031] refer to Figure 1-5 , a kind of crushing and separating equipment for waste plastic regeneration, comprising a fixed cylinder 1, an active rotating cylinder 2 is arranged inside the fixed cylinder 1, a bucket end 5 is welded on the top of the fixed cylinder 1, and a bucket end 5 is welded on the central axis of the top end of the bucket end 5 A horizontal plate, the bottom outer wall of the horizontal plate is fixed with a rotating motor 6 by bolts, and the output shaft of the rotating motor 6 is connected to a bracket 3 through a coupling, the end of the bracket 3 is welded to the top outer wall of the driving drum 2, and the bracket 3 The outer walls of both sides are welded with equidistantly distributed hammers 4, and the circumferential inner wall of the active drum 2 is welded with equidistantly distributed sharp rods 11, and one end of the sharp rods 11 is welded with a C-shaped stab 10, and the active drum 2 2 The opposite side of the fixed cylinder 1 is fixedl...

Embodiment 2

[0041] This embodiment discloses a crushing and separating method for crushing and separating equipment for recycling waste plastics. The specific steps include: the operator controls and starts the rotating motor 6, and the rotating motor 6 drives the support 3 and the active drum 2 to rotate rapidly. The plastic is put into the bucket end 5, and the hammer 4 is used to cooperate with the top edge 7 on the top of the fixed pole 18 to pre-shred the plastic; , the triangular tip block 8 relatively rotates quickly, and utilizes the triangular block one 29, the triangular block two 30 and the attached support block 31 to rotate relatively, so as to play the role of grinding and crushing, and refine the plastic; utilize the bottom ring 13, the tooth The disc 27 is driven by the drive belt 26 and the worm 24 to drive the runner 23 to rotate, so that the drive rod 22 cooperates with the connection spring 15 and the connection spring 2 20 to drive the sieve moving net box 19 to vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com