Method for compensating heating of PTC (Positive Temperature Coefficient) heating element during charging of electric vehicle

A technology of electric vehicles and heating parts, which is applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of reducing user experience, lagging power of charging piles, and increasing charging time, so as to shorten charging time and improve satisfaction The effect of increasing the charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

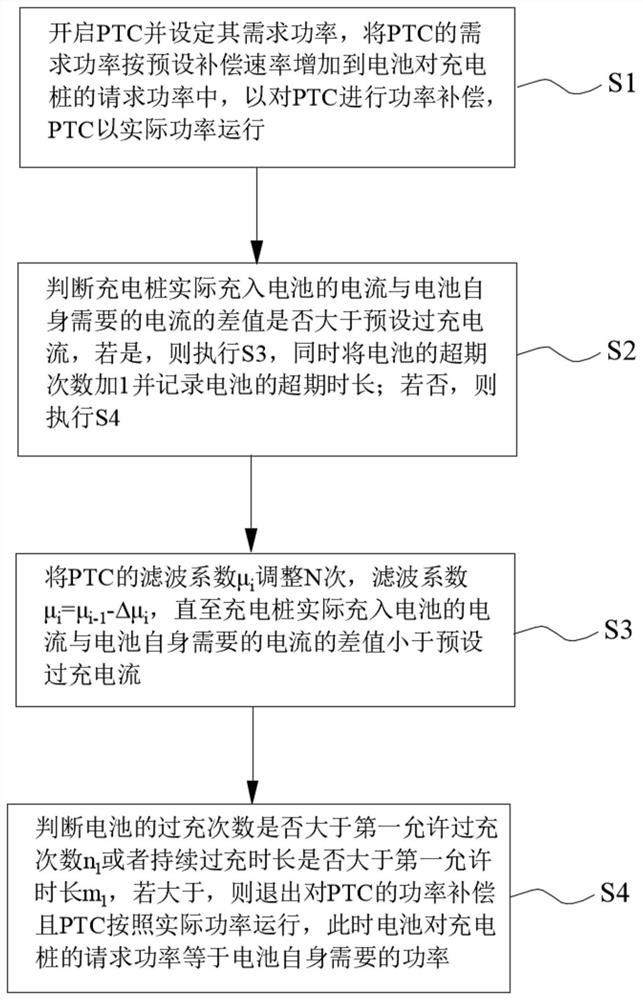

[0035] This embodiment provides a method for compensating the heating of the PTC heating element when charging an electric vehicle, such as figure 1 shown, including:

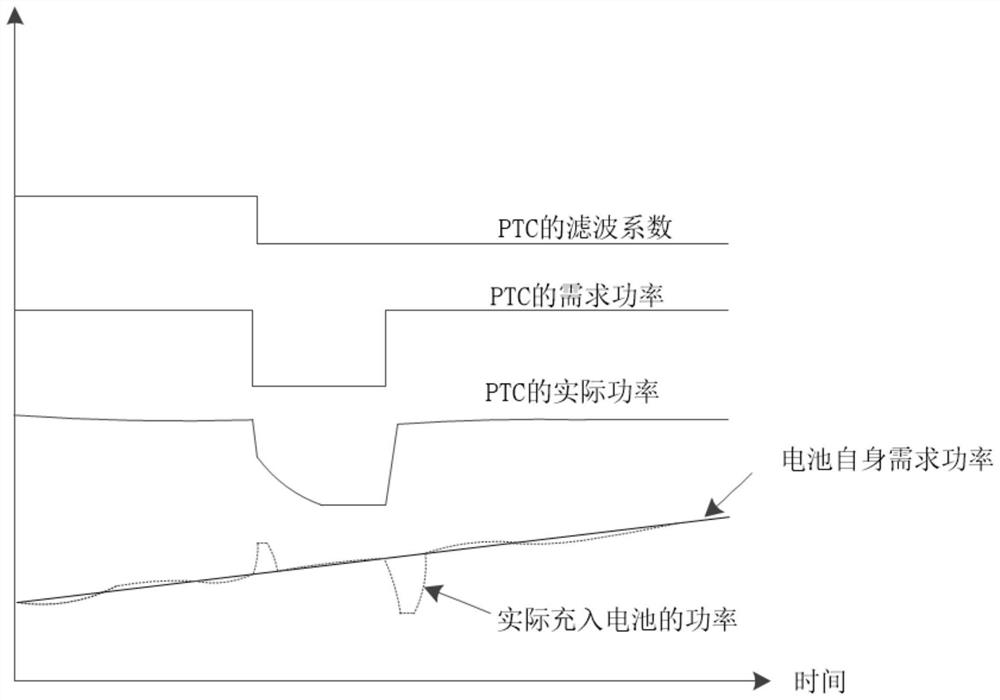

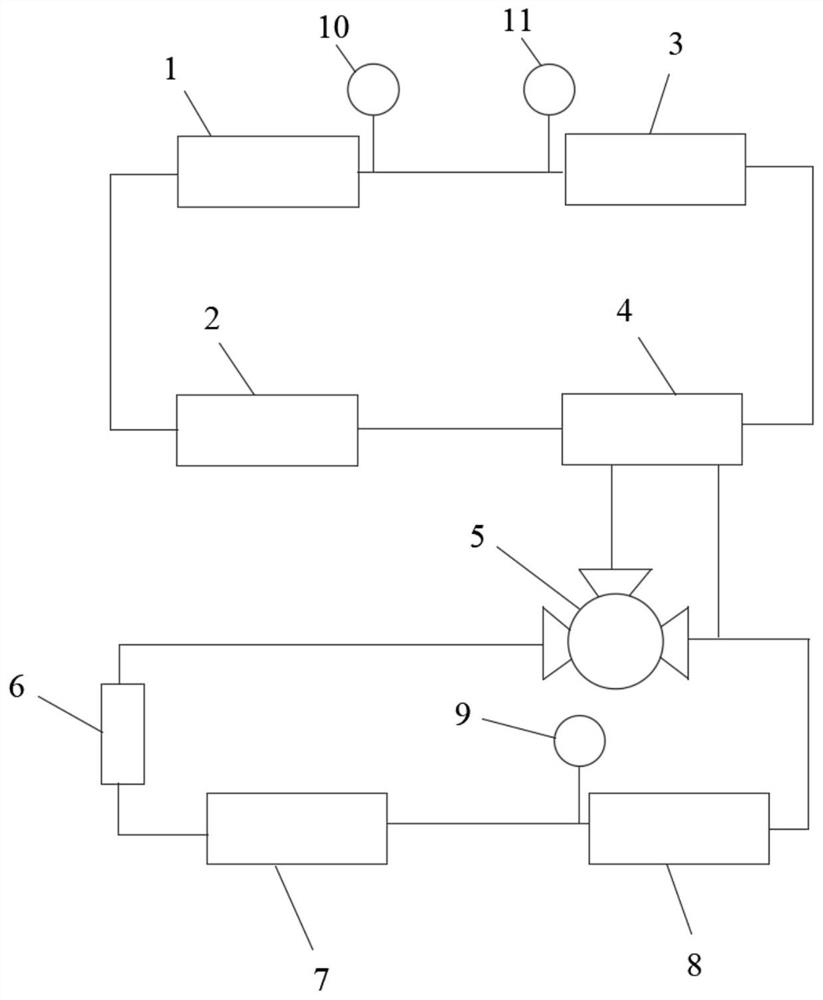

[0036] S1, open the PTC heating element 1 (such as image 3 shown) and set its required power, and increase the required power of the PTC heating element 1 to the battery 8 at a preset compensation rate (such as image 3 As shown) in the requested power of the charging pile, the PTC heating element 1 is used for power compensation, and the PTC heating element 1 operates at the actual power;

[0037] S2. Determine whether the difference between the current actually charged into the battery 8 by the charging pile and the current required by the battery 8 itself is greater than the preset overcharge current. Timeout period; if not, execute S4;

[0038] S3, the filter coefficient μ of the PTC heating element 1 i Adjust N times, filter coefficient μ i =μ i-1 -Δμ i , until the difference between the current ac...

Embodiment 2

[0066] This embodiment provides a method for compensating the heating of the PTC heating element when charging an electric vehicle, including:

[0067] S01. When charging the battery 8, the battery 8 requests the power required by the battery 8 from the charging pile according to its state of charge and temperature;

[0068] S02. After a period of time, the output power of the charging pile increases at a preset charging rate;

[0069] S1. Turn on the PTC heating element 1 and set its required power, and increase the required power of the PTC heating element 1 to the power requested by the battery 8 for the charging pile at a preset compensation rate, so as to perform power compensation for the PTC heating element 1, and then When the PTC heating element 1 runs at the actual power, judge whether the output power of the charging pile is greater than the instantaneous overcharge preset power of the battery 8; 8, until the output power of the charging pile is less than the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com