Guide wheel applied by new material based on crawler-type engineering machinery and production process of guide wheel

A technology of construction machinery and production technology, which is applied in the direction of tracked vehicles, motor vehicles, manufacturing tools, etc., can solve the problems of increased cracking and wear, cracking, and increased difficulty in dismounting fixing bolts, so as to achieve the effect of strengthening strength, convenient disassembly, and realizing cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

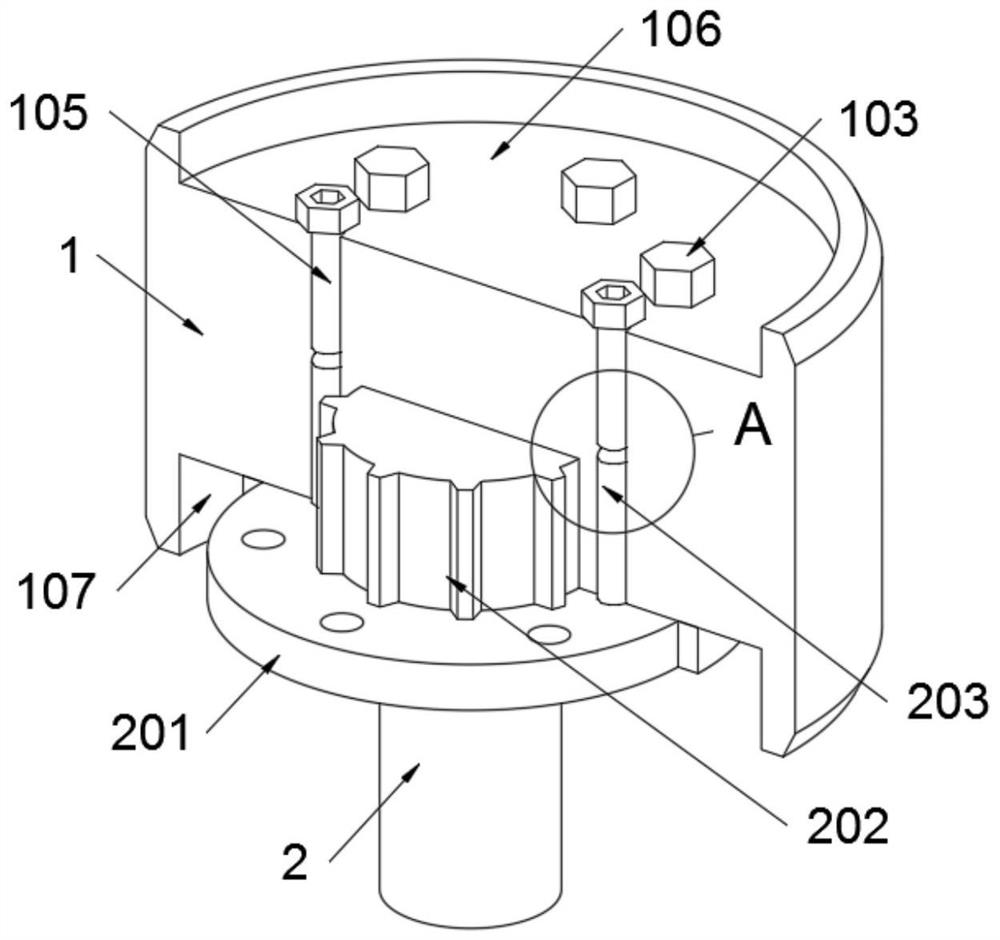

[0060] as attached figure 1 to attach Figure 8 Shown:

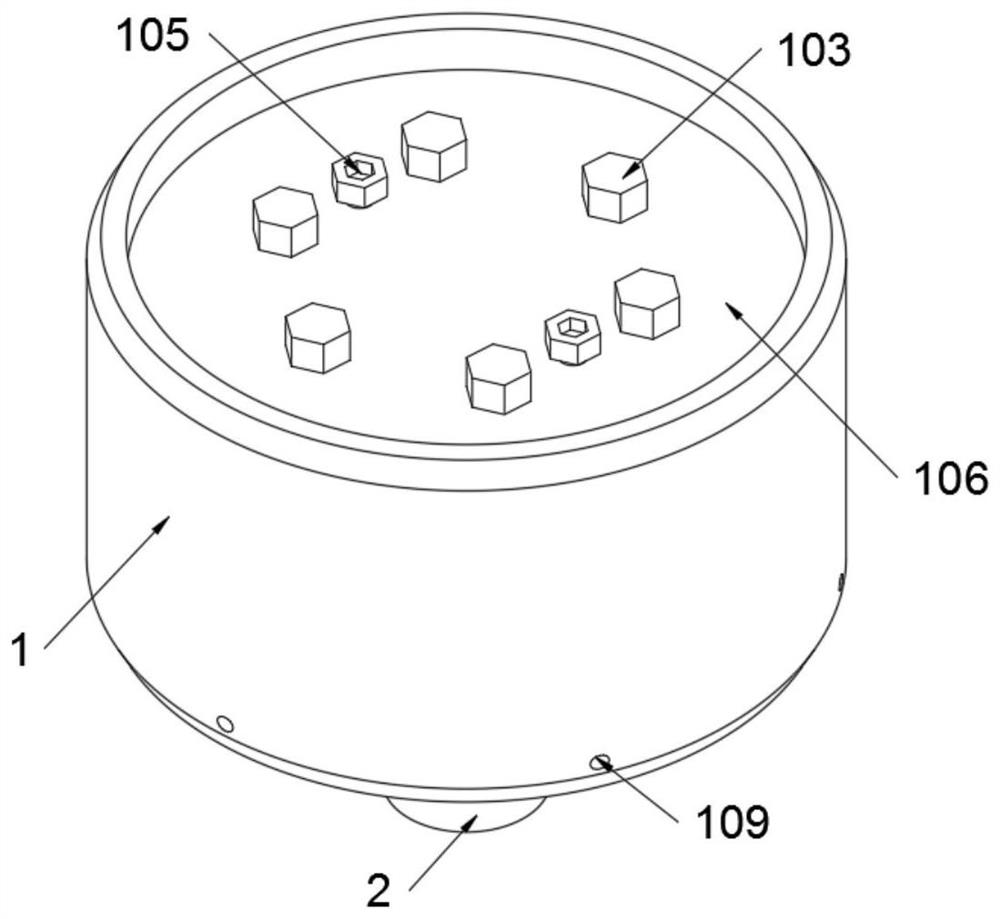

[0061] The invention provides a guide wheel based on crawler-type construction machinery using new materials and a production process thereof, including a guide wheel main body 1;

[0062] The guide wheel main body 1 is a circular wheel body structure;

[0063] Guide wheel main body 1 includes:

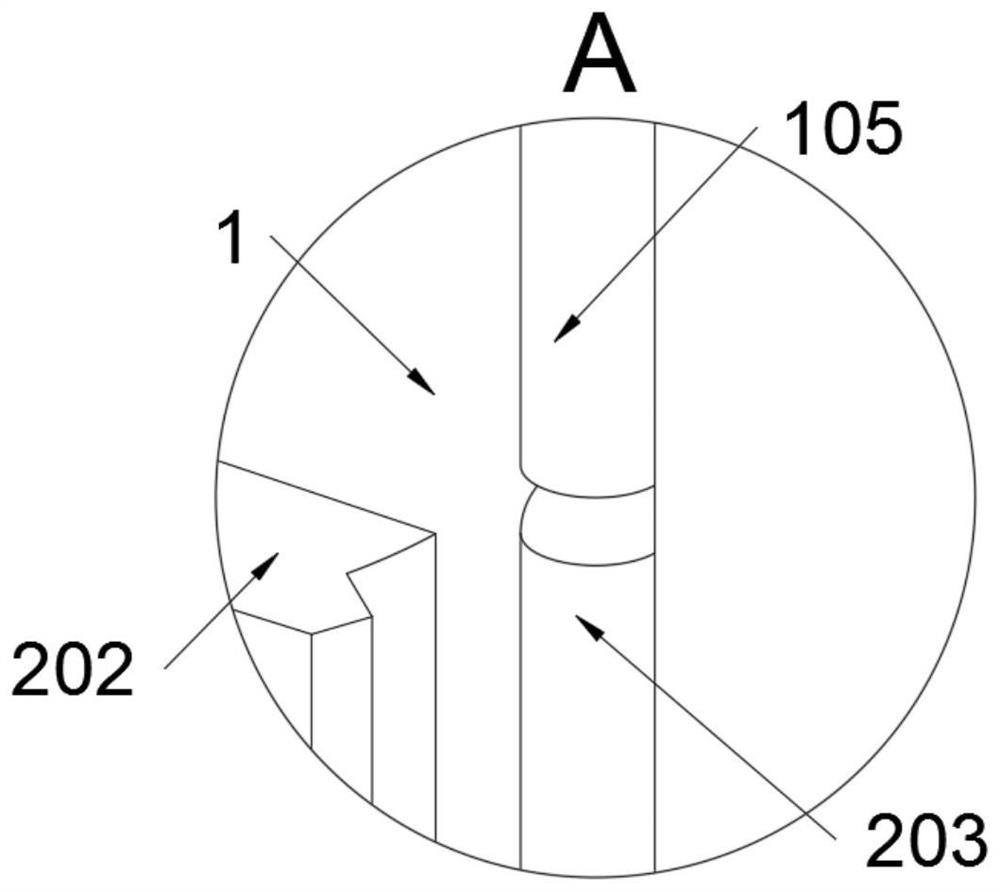

[0064] Slot 101, the slot 101 is made up of a cylindrical groove and eight keyways of trapezoidal structure;

[0065] Drive shaft 2, drive shaft 2 is installed on the guide wheel main body 1.

[0066] Reference as Image 6 , drive shaft 2 consists of:

[0067] The stopper 201, the stopper 201 is a cylindrical plate structure, and the stopper 201 is arranged on the head end of the drive shaft 2;

[0068] Plug 202, the plug 202 is arranged on the top surface of the stopper 201, and the plug 202, the stopper 201 and the drive shaft 2 are integrally molded; the plug 202 matches the slot 101, and the plug 202 is plugged into t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap