Protective device for special chip for full life cycle management of rubber roller

A technology with a full life cycle and protective device, applied in the direction of collaborative operation devices, special packaging objects, transportation and packaging, etc., can solve the problems of the impact of the work progress of the enterprise, the processing efficiency of the rubber roller processing enterprise, and the unknown life cycle, etc. The effect of improving the efficiency of on-site roll management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

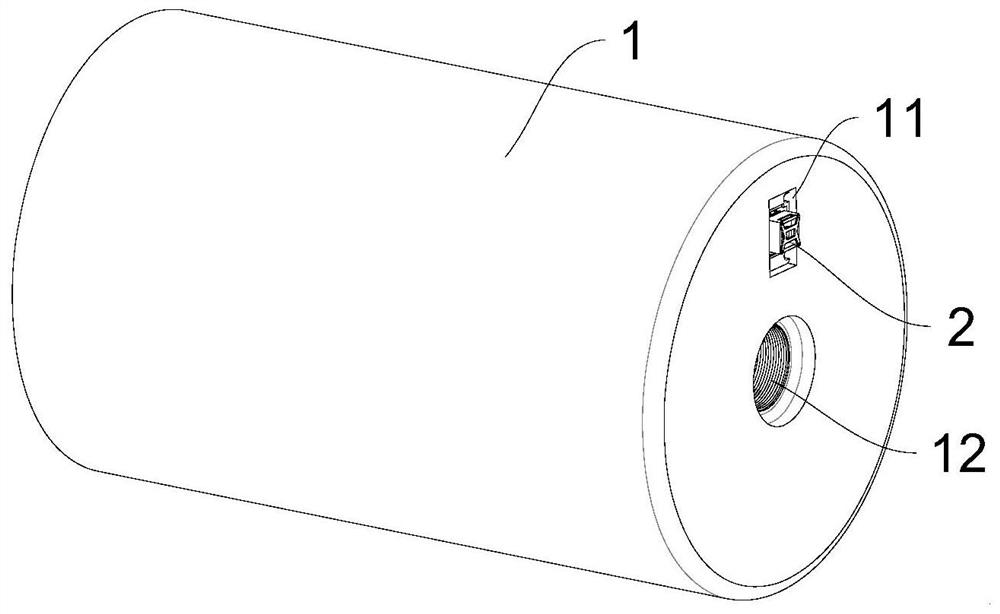

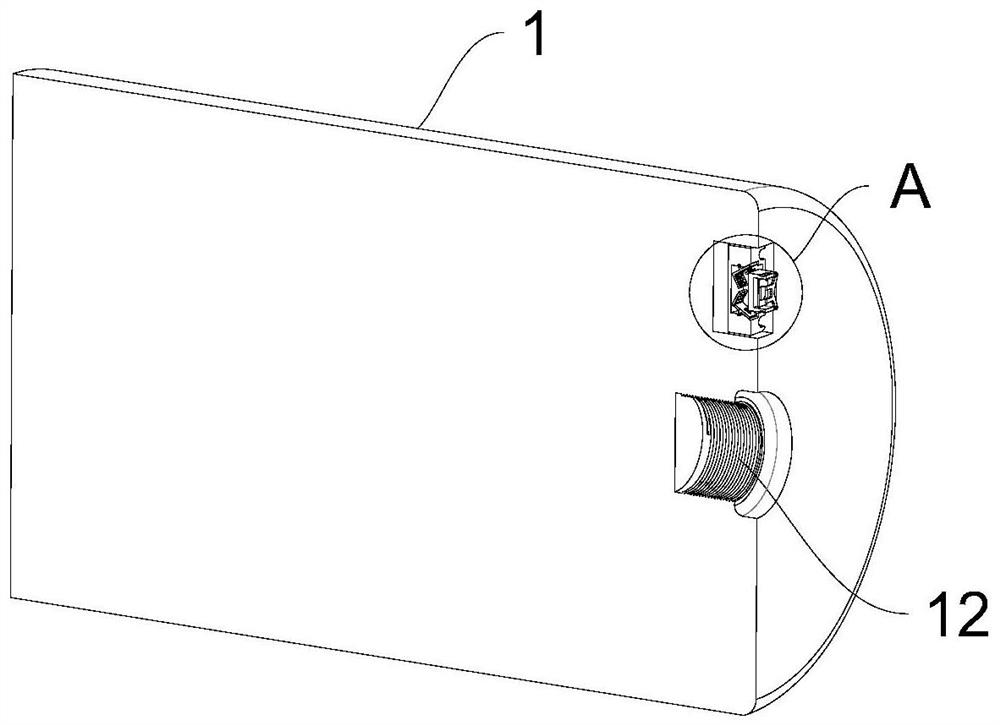

[0040] As an embodiment of the present invention, a placement groove 11 is opened on one end surface of the rubber roller 1, and a threaded hole 12 is opened in the middle of one end of the rubber roller 1; the protection mechanism 2 is arranged in the placement groove 11 .

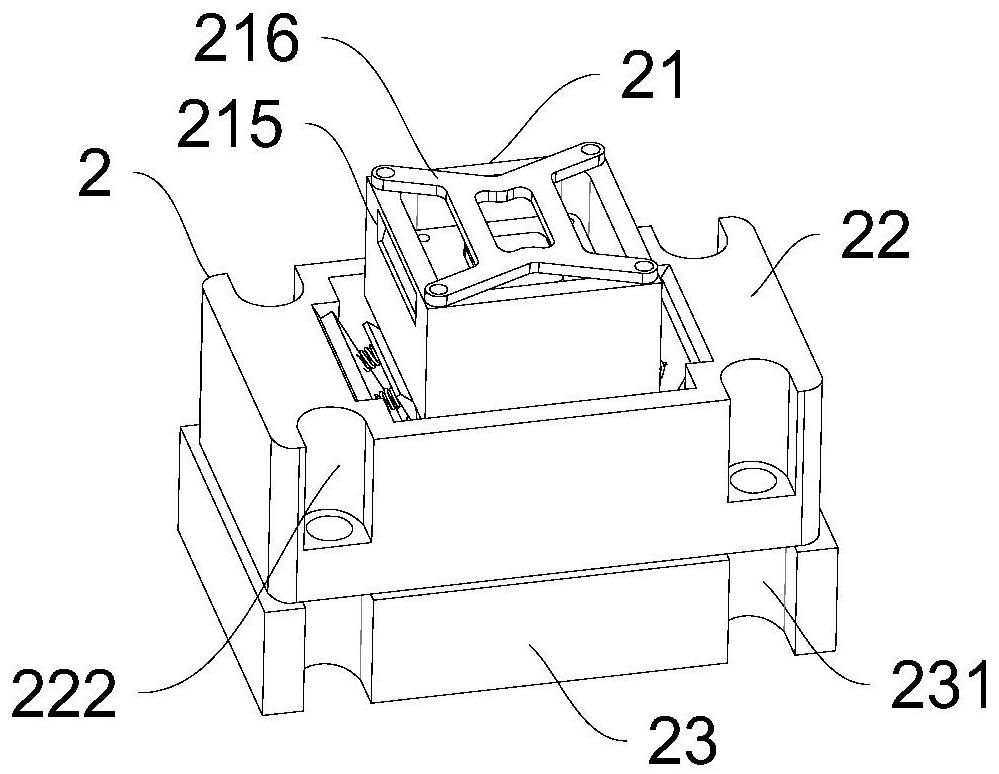

[0041] In this technique, the placement groove 11 provided on the rubber roller 1 has a rectangular structure corresponding to the rectangular structure of the outer protective block 22, and a connecting seat is provided at the bottom of the placement groove 11. When the outer protective block 22 is placed therein, It is fixed in the placement groove 11 together with the support block 23 by screws, and the support block 23 is located at the bottom of the outer protection block 22 to play a supporting role.

[0042] As an embodiment of the present invention, the support block 23 is fixedly connected to the bottom of the placement groove 11 , and four corners of the support block 23 are provided with throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com