Modified PP reclaimed material and preparation method thereof

A recycled material and modification technology, which is applied in the field of modified PP recycled material and its preparation, can solve the problems of poor fusion, high viscosity, unfavorable industrialization, etc., and achieve the effects of improving impact strength, increasing contact area, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

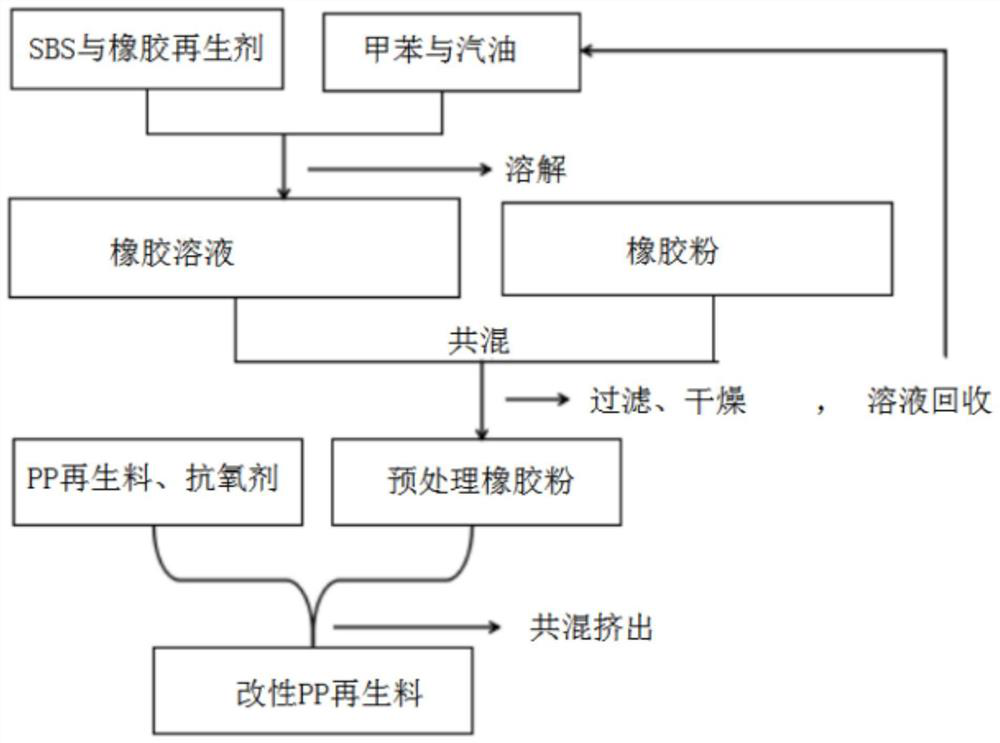

[0032] A preparation method of modified PP recycled material, comprising the following steps,

[0033] S1: Add rubber regeneration agent and compatibilizer into the reactor, and blend uniformly to obtain a rubber solution. Preferably, an organic solvent obtained by mixing toluene and gasoline is also added, and the toluene in the organic solvent is used for dissolving. Gasoline can dry quickly, and the compatibilizer is preferably low-polarity SBS or SBR. A low-viscosity rubber solution composed of SBS or SBR, rubber regeneration agent and an organic solvent made from toluene and gasoline is beneficial to Increase the fusion degree of subsequent rubber powder and PP recycled materials;

[0034] S2: uniformly blending the rubber solution prepared in S1 with rubber powder, filtering, and drying to obtain pretreated rubber powder, wherein the filtrate can be condensed and recovered to be used as a rubber solution;

[0035] S3: Blend and extrude the pretreated rubber powder prepa...

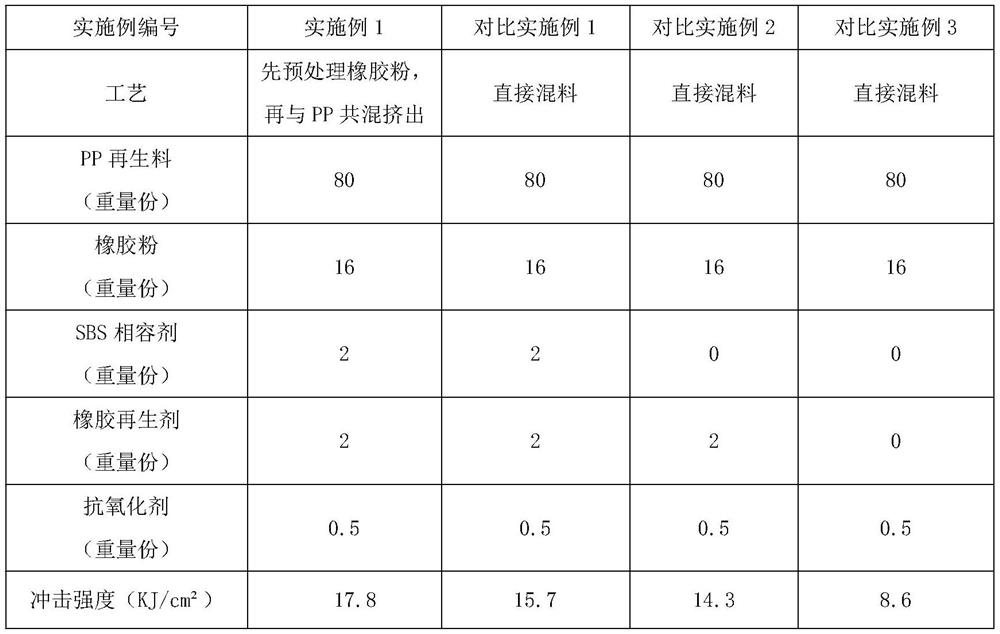

Embodiment 1

[0054] Such as figure 2 as shown,

[0055] S1: Mix 2 parts by weight of SBS and 2 parts by weight of rubber regeneration agent to prepare a rubber solution.

[0056] S2: Mix and stir the rubber solution prepared in S1 and rubber powder evenly, centrifugally filter, and dry at room temperature to obtain pretreated rubber powder, and the filtrate after filtration is condensed and recycled as rubber solution. By controlling the rotational speed and centrifugation time of the centrifuge, the rubber powder in the pretreated rubber powder: SBS: rubber regeneration agent = 16:2:2.

[0057] S3: Mix 20 parts by weight of pretreated rubber powder prepared in S2, 80 parts by weight of PP regenerated plastic, and 0.5 parts by weight of antioxidant, and then mix and extrude granules in a screw extruder at 205°C, preferably Ground, screw speed: 75 rpm.

Embodiment 2

[0059] Such as figure 2 as shown,

[0060] S1: Dissolving 5 parts by weight of SBS and 5 parts by weight of rubber regeneration agent in 90 parts by weight of an organic solvent mixed with toluene and gasoline to prepare a rubber solution, wherein the weight ratio of toluene to gasoline is 1: 1. The solid content of the rubber solution is 5%, and the solution viscosity is 500mpa.s. By controlling the rotational speed and centrifugation time of the centrifuge, the rubber powder in the pretreated rubber powder: SBS: rubber regeneration agent = 20:5:5.

[0061] S2: Mix and stir the rubber solution prepared in S1 and rubber powder evenly, centrifugally filter, and dry at room temperature to obtain pretreated rubber powder, and the filtrate after filtration is condensed and recycled as rubber solution.

[0062] S3: Mix 20 parts by weight of pretreated rubber powder prepared in S2, 80 parts by weight of PP regenerated plastic, and 0.5 parts by weight of antioxidant, and then mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com