Hydropower station flood discharge flow channel outlet suspended slope fast-assembly maintenance platform and installation method thereof

A technology of flood discharge channel and maintenance platform, which is applied in the fields of hydropower stations, hydropower generation, water conservancy projects, etc., can solve the problems of inflexible installation and dismantling, hidden safety hazards, incompatibility, etc., and achieves a wide range of installation applications and safe use Reliable, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

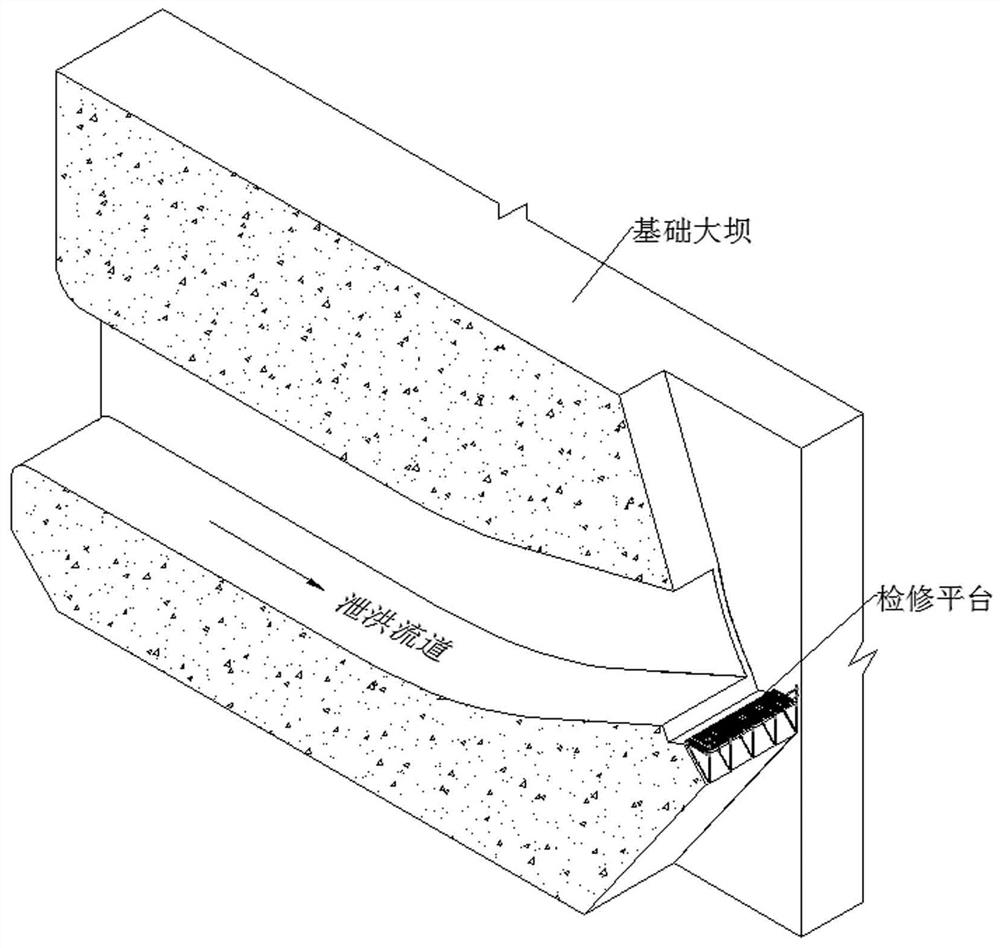

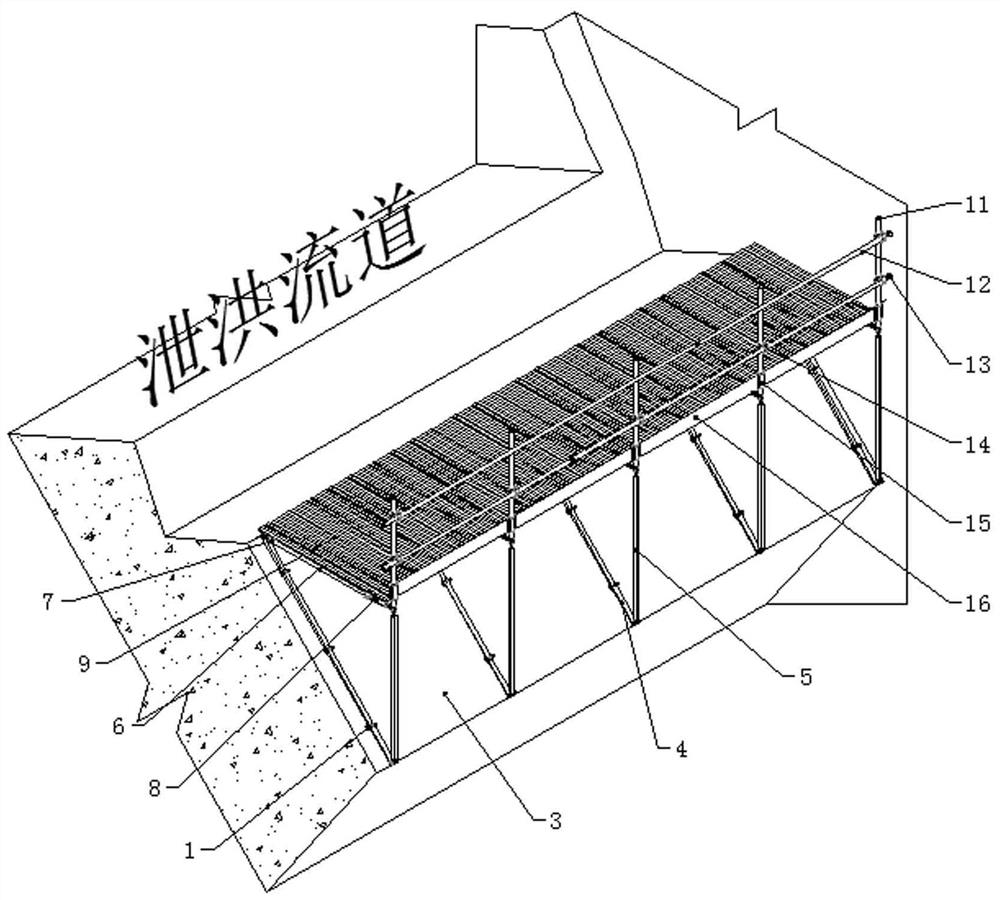

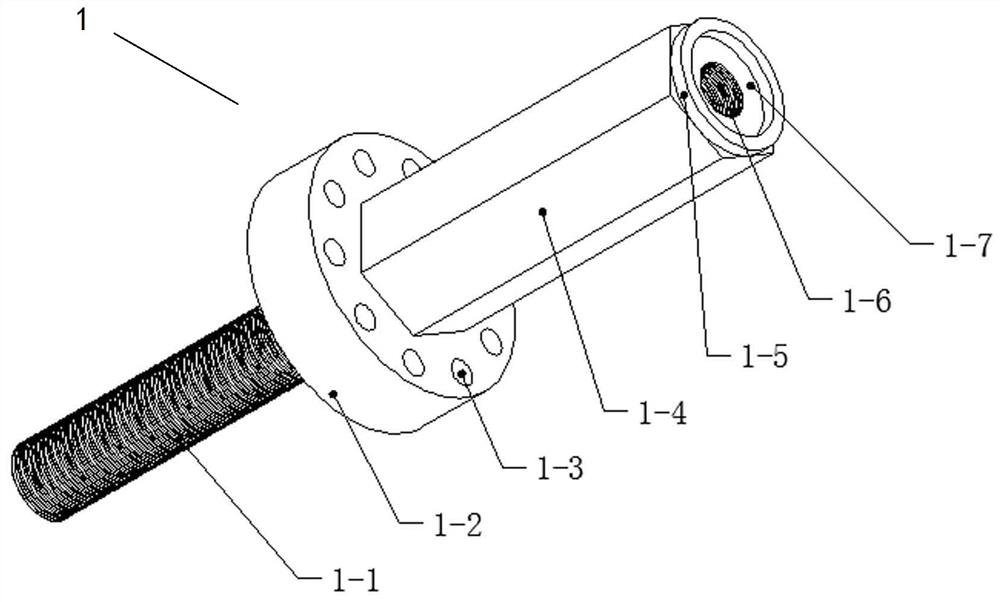

[0042] Such as Figure 1-18 Among them, the quick-installation maintenance platform on the suspended slope at the outlet of the flood discharge channel of the hydropower station includes foundation embedded parts, support structures, platform structures and protective structures. In the inclined surface of the foundation, a plugging cover 2 is provided on the foundation thread seat 1, and a protective plate 3 is provided between the foundation thread seat 1 and the supporting structure;

[0043]The support structure includes a slanted column 4, a vertical column 5, a horizontal bar 6, a reinforcing beam 7 and a locking clip 8, and the two ends of the slanted column 4 are provided with a fixed hinge seat 4-1 and a plurality of threaded seats 1 to cooperate with the foundation. The bolt installation through hole 4-2, the bottom of the column 5 is provided with the first movable support hinge 5-1 that cooperates with the fixed hinge seat 4-1 by the bolt, and the top of the column...

Embodiment 2

[0055] Such as Figure 1-18 Among them, the installation method of the quick-installation maintenance platform on the suspended slope at the outlet of the flood discharge channel of the hydropower station is as follows:

[0056] 1. Pre-embed multiple sets of basic threaded seats 1 in the concrete of the suspended slope by means of chemical value reinforcement;

[0057] 2. When building the maintenance platform, first install the protective plate 3 through the installation through hole 3-1 with multiple sets of basic threaded seats 1, and then install and connect the inclined column 4 with the basic threaded seat 1 by threaded connection;

[0058] 3. Connect the two ends of the inclined column 4 to the column 5 and the horizontal bar 6 through the fixed hinge seat 4-1, then adjust the height of the positioning nut 5-3 on the column 5 to keep the horizontal bar 6 in a horizontal position, and then pass the second A locking nut 5-4 is fixed;

[0059] 4. Place the reinforcing be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com