Grouting water disaster prevention and control method considering mining-induced fracture influence

A grouting and water hazard technology, applied in drainage, mining equipment, earth-moving drilling, etc., can solve problems such as rock movement control, overburden damage, etc., and achieve the effect of solving water hazard prevention and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

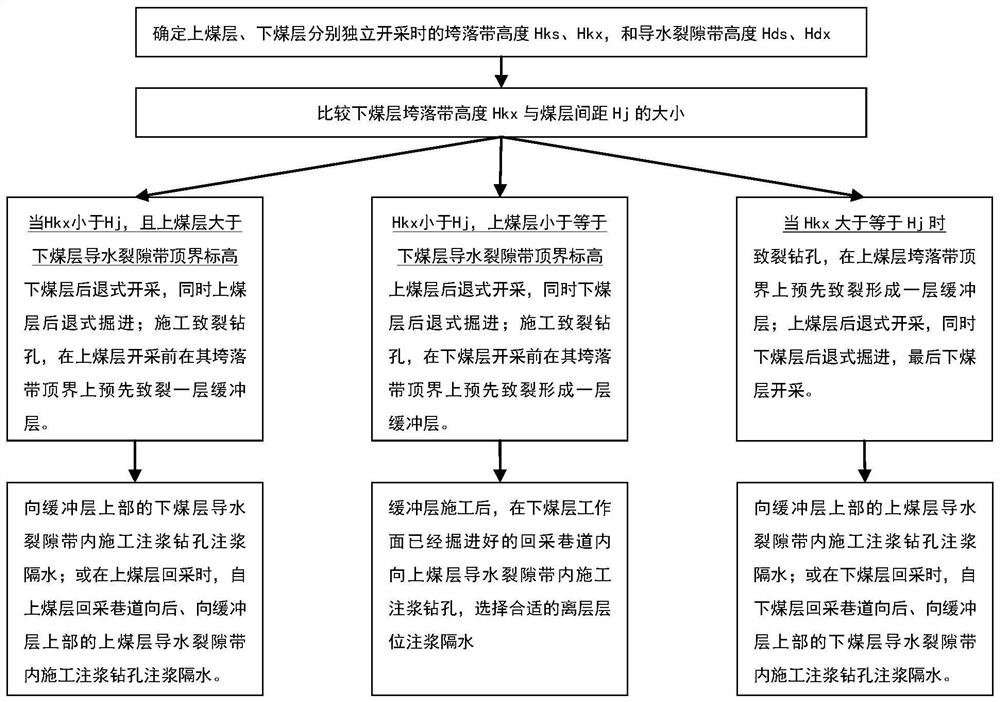

[0031] A grouting water disaster prevention method considering the impact of mining fissures, the working conditions include an upper coal seam and a lower coal seam with similar distances; the distance between the upper coal seam and the lower coal seam is Hj, that is, the thickness of the rock layer between the upper coal seam and the lower coal seam is Hj; There is an aquifer at a short distance above the upper coal seam, and the distance between the upper coal seam and the aquifer is Hh; the water damage comes from the aquifer, and the mining fracture is the collapse zone and water-conducting fracture zone produced by coal seam mining;

[0032] The method for preventing and controlling water damage comprises the steps of:

[0033] S1, according to the overlying rock lithology above the coal seam, combined with the mining height of the coal seam, determine the caving zone heights Hks, Hkx, and water-conducting fissure zone heights Hds, Hdx when the upper coal seam and the lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap