Rapid warming-up system and method for multi-compressor lubricating system

A lubricating system and compressor technology, applied in the field of compressor warm-up, can solve problems such as poor fluidity, difficulty in absorbing oil by the oil pump, and high viscosity of lubricating oil, so as to reduce heat load, shorten warm-up time, and reduce The effect of footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

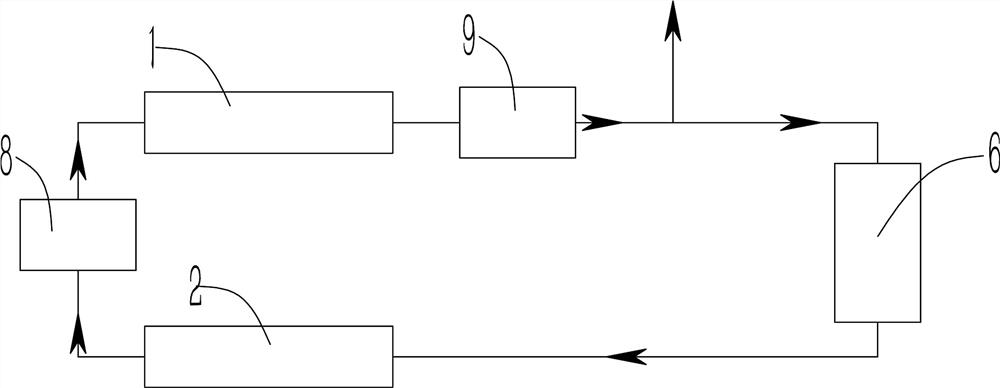

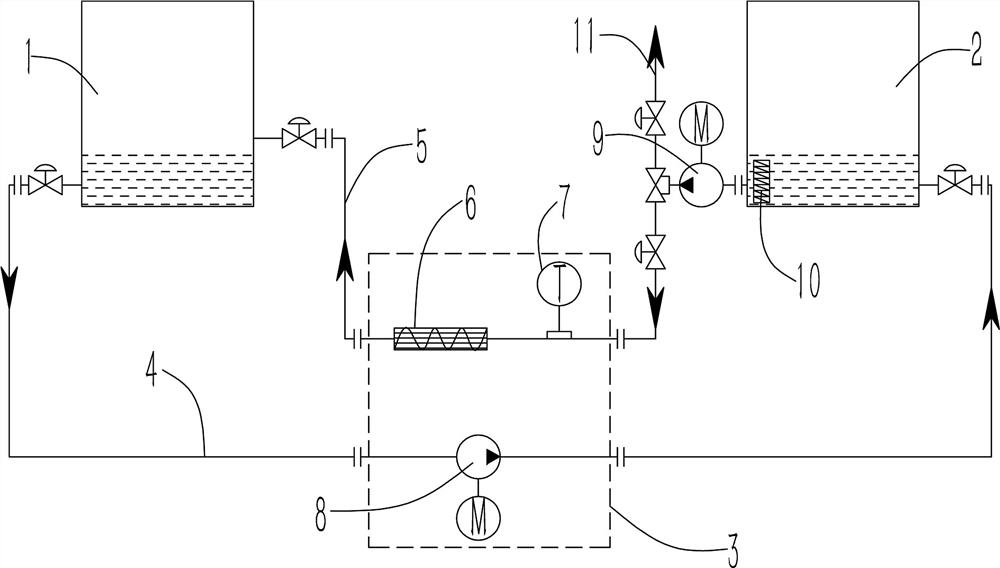

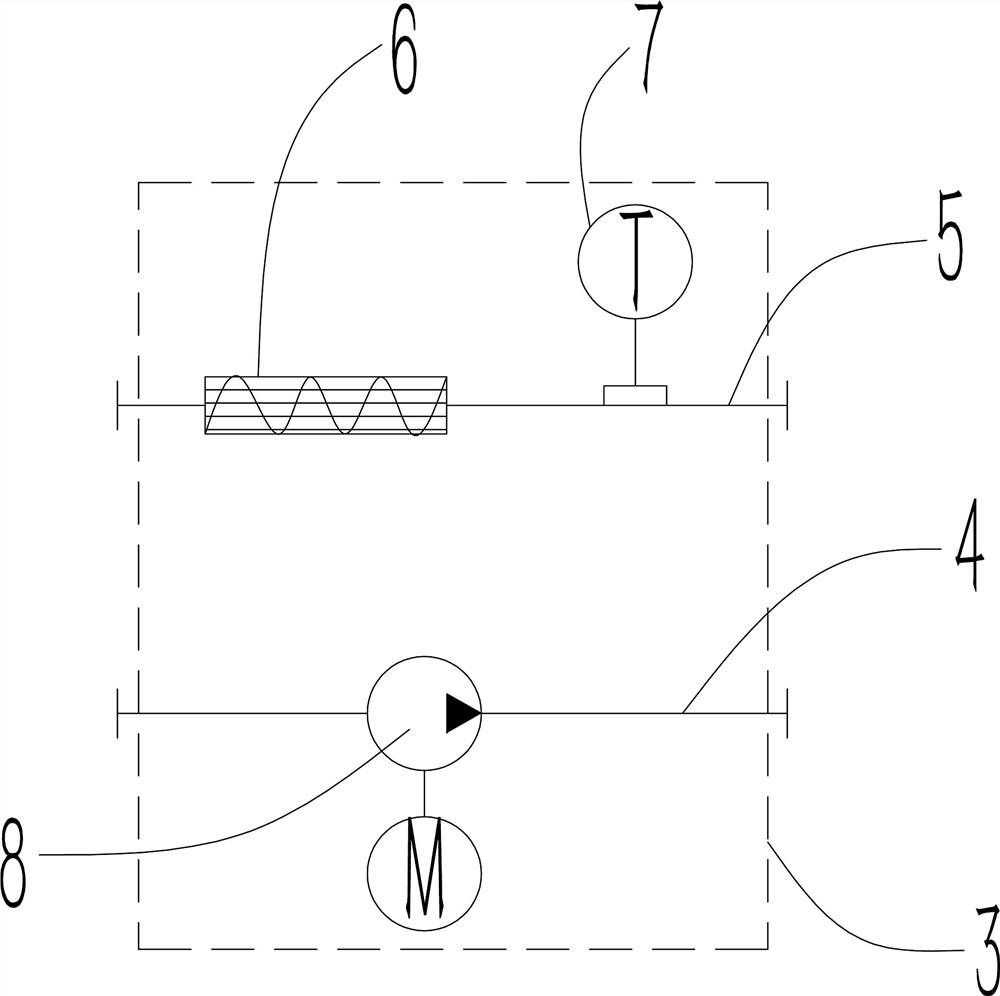

[0030] Such as Figure 1~3 As shown, the rapid warm-up system and method for multiple compressor lubrication systems includes a replacement heating module 3 installed between the operating compressor 1 and the warm-up compressor 2. The replacement heating module 3 includes a return line 4 and a replacement Pipeline 5, the operating compressor 1 communicates with the warm-up compressor 2 through the return pipeline 4 and the replacement pipeline 5 to form a circuit, the replacement pipeline 5 is provided with a baffle heater 6, and the return pipeline 4 is provided with The first oil pump 8;

[0031] The low-temperature lubricating oil in the warm-up compressor 2 is heated by the baffle heater 6 on the replacement pipeline 5, and then passed into the running compressor 1, and mixed with the high-temperature lubricating oil in the running compressor 1, and then The first oil pump 8 on the return line 4 is driven into the warm-up compressor 2, and the low-temperature lubricating...

Embodiment 2

[0042] Such as Figure 1~3 , combined with Example 1 to further illustrate: connect the replacement heating module 3 with the operating compressor 1 and the warm-up compressor 2 to form a circuit; open the control valve to connect the replacement pipeline 5, and start the heater in the warm-up compressor 2 10. Ensure the fluidity of the cooling oil in the warm-up compressor 2; start the second oil pump 9 to quickly heat the lubricating oil in the warm-up compressor 2 through the baffle heater 6 and then pass it into the running compressor 1 ;The lubricating oil passed into the operating compressor 1 is fully mixed with the hot oil in the operating compressor 1, and the waste heat in the operating compressor 1 is used to speed up the heating speed of the cold oil; open the control valve to connect the return line 4. Start the first oil pump 8, and control the flow rate of the first oil pump 8 and the second oil pump 9 to be the same, so that the hot oil in the operating compres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap