Pit type intermediate case for restraining flow separation

A flow separation and intermediary technology, applied in the direction of fluid flow, mechanical equipment, etc., to achieve the effect of improving aerodynamic performance, increasing kinetic energy level, and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

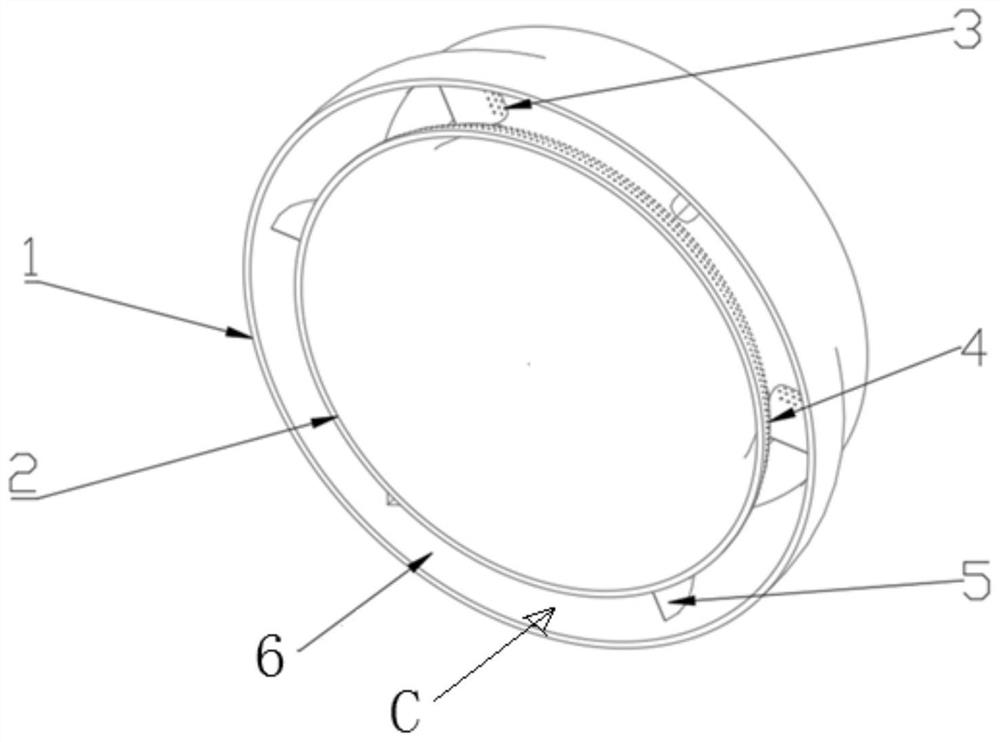

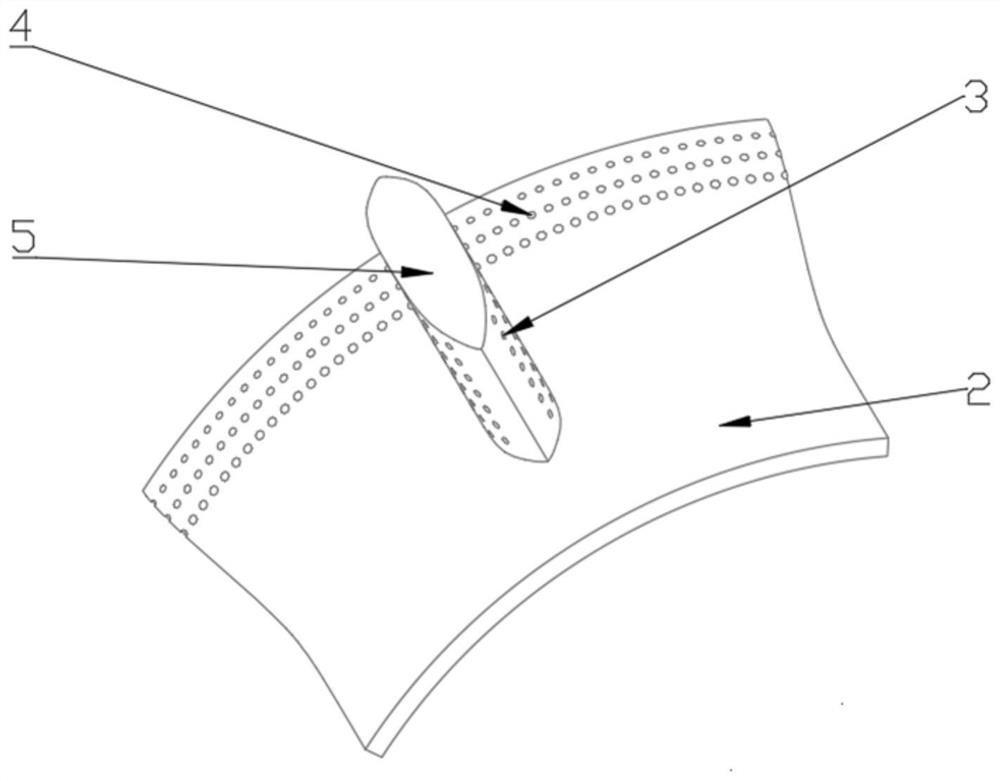

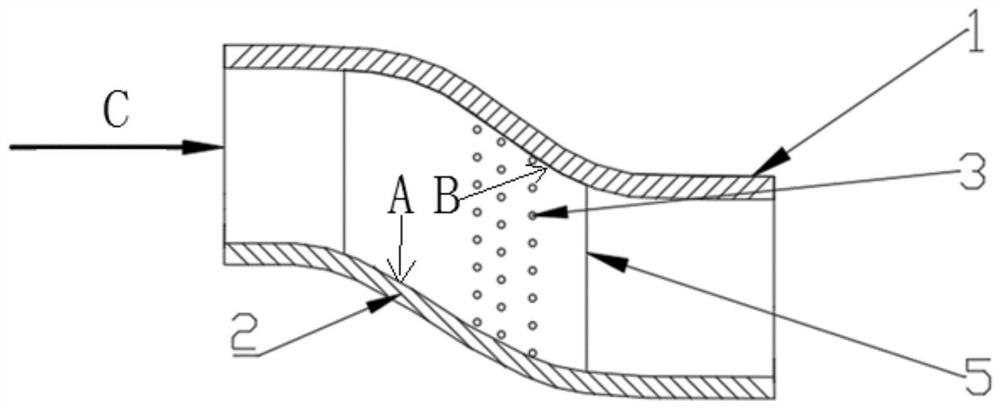

[0019] like figure 1 , figure 2 and image 3 Shown is the pit-type intermediate casing for suppressing flow separation disclosed in the present invention, comprising an intermediate casing outer ring 1, an intermediate casing inner ring 2 and a plurality of support plates 5;

[0020] The intermediate casing inner ring 2 is placed in the intermediate casing outer ring 1 , and a flow annular channel 6 is formed between the intermediate casing inner ring 2 and the intermediate casing outer ring 1 . The plates 5 are evenly distributed in the flow annular channel 6 in the circumferential direction, and one end is connected with the outer wall of the intermediate casing inner ring 2, and the other end is connected with the inner wall of the intermediate casing outer ring 1. The back arc of the flow annular channel 6 and / Or the support plate 5 is further provided with a dimple for generating a vortex when the fluid flows.

[0021] Specifically, in this embodiment, both the back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com