Crescent dune type impact air film cooling structure with transverse air flow grooves

A technology of horizontal airflow and film cooling, applied in the direction of supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problems of reduced film cooling effect, mixing, etc., to enhance the effect of sticking to the wall, prevent dead zones, Enhanced effect of spanwise uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with the accompanying drawings, the present invention will be further described:

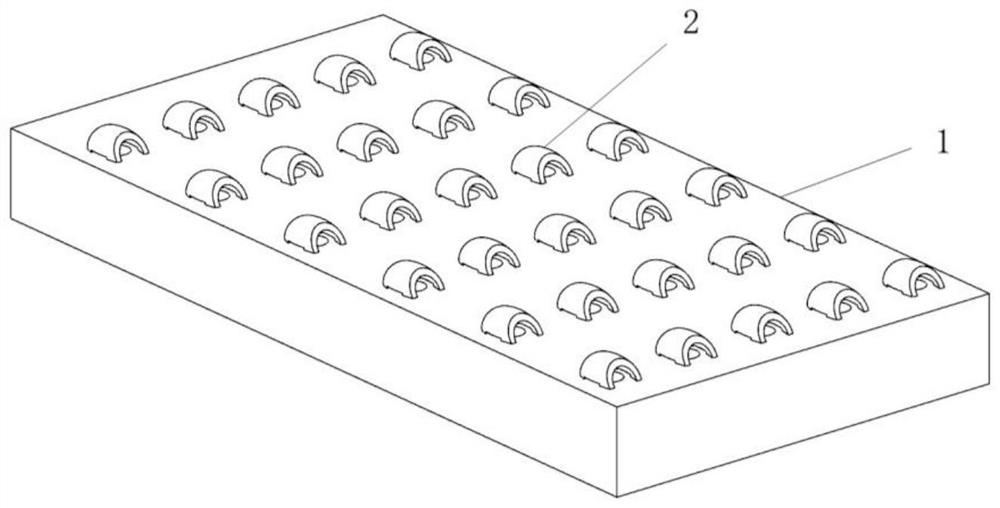

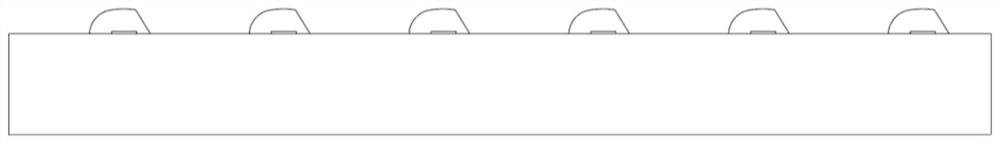

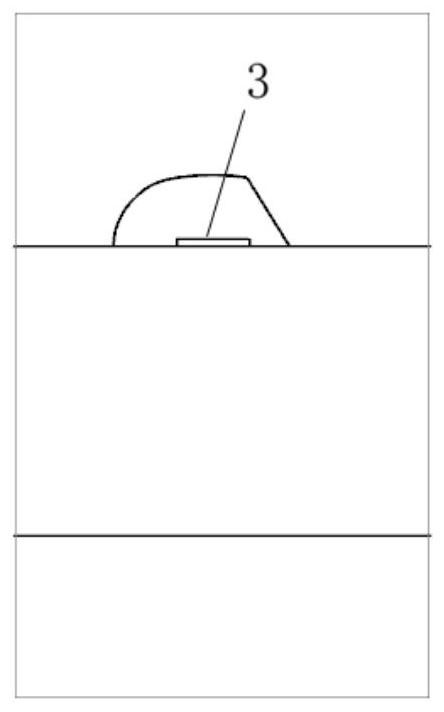

[0021] combine figure 1 , figure 2 , image 3 , Figure 4 , The present invention is a crescent dune type impingement air film cooling structure with transverse air flow grooves. figure 1 is a positive triaxial survey of the present invention, figure 2 is a side view of the present invention, image 3 It is a partial enlarged view of the crescent dune-shaped air film cover with transverse air flow grooves of the present invention, Figure 4 It is a sectional view of the present invention.

[0022] The wall surface structure 1 with a certain thickness is cooled by gas film, and the cooling medium flows out from the cylindrical gas film inclined hole 4 in the wall surface. At the outlet of the air film hole, the air film cover 2 of the crescent dune type will be impacted in the form of an impinging jet. The air film cover can effectively restrain the cooling medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com