Coating pressure barrel capable of accurately controlling temperature

A technology of precise temperature control and pressure barrel, which is applied in the direction of pressure vessels, coatings, and devices for coating liquid on the surface, etc., can solve problems such as temperature changes of coatings, achieve the effects of reducing influence, facilitating production, and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

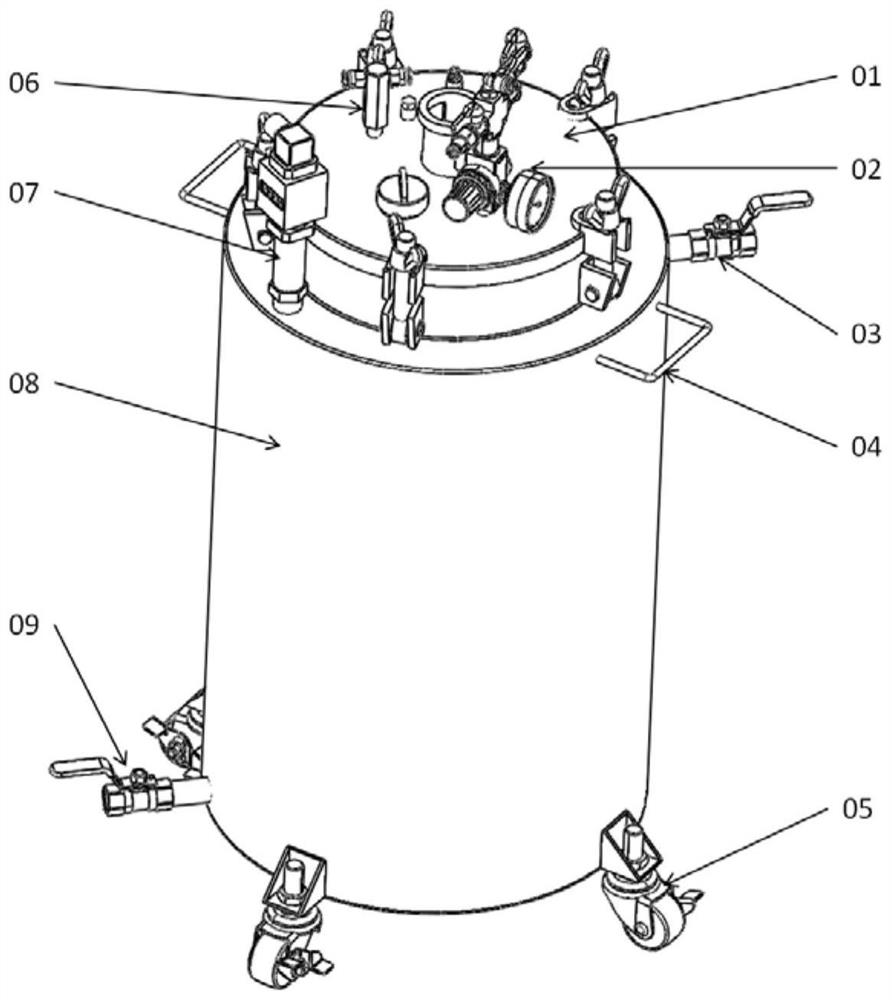

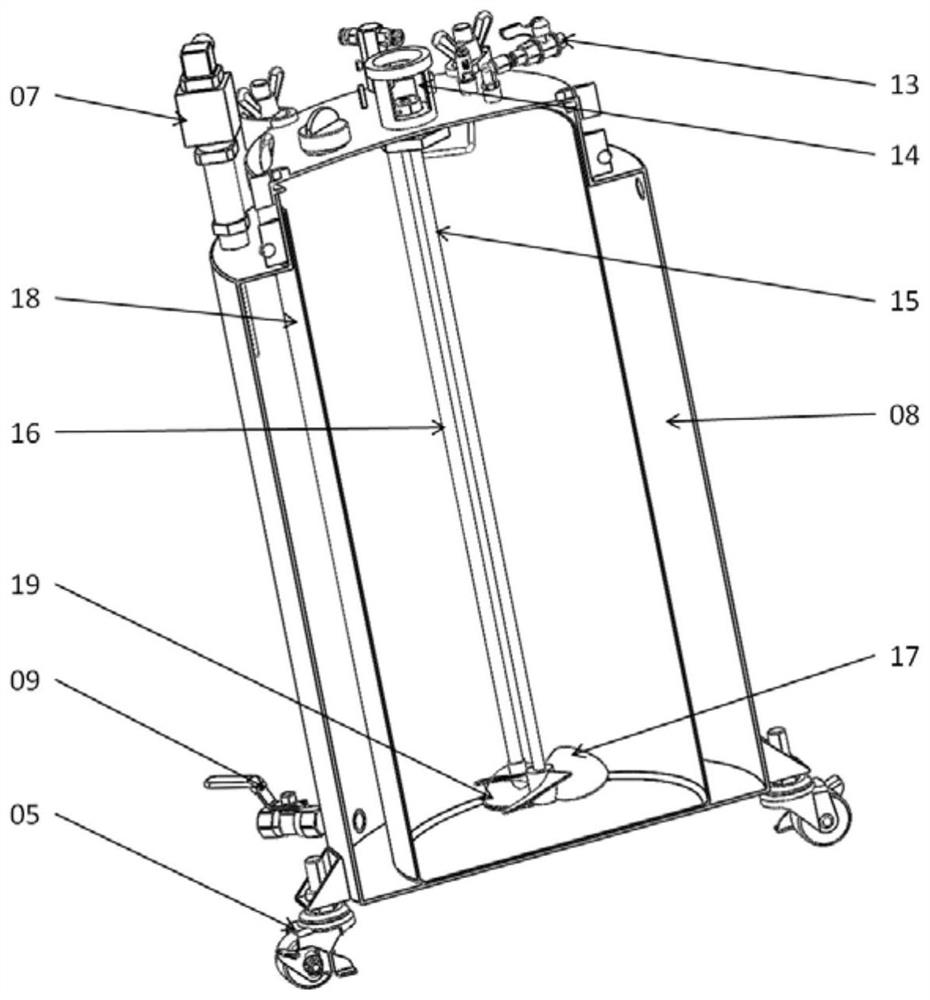

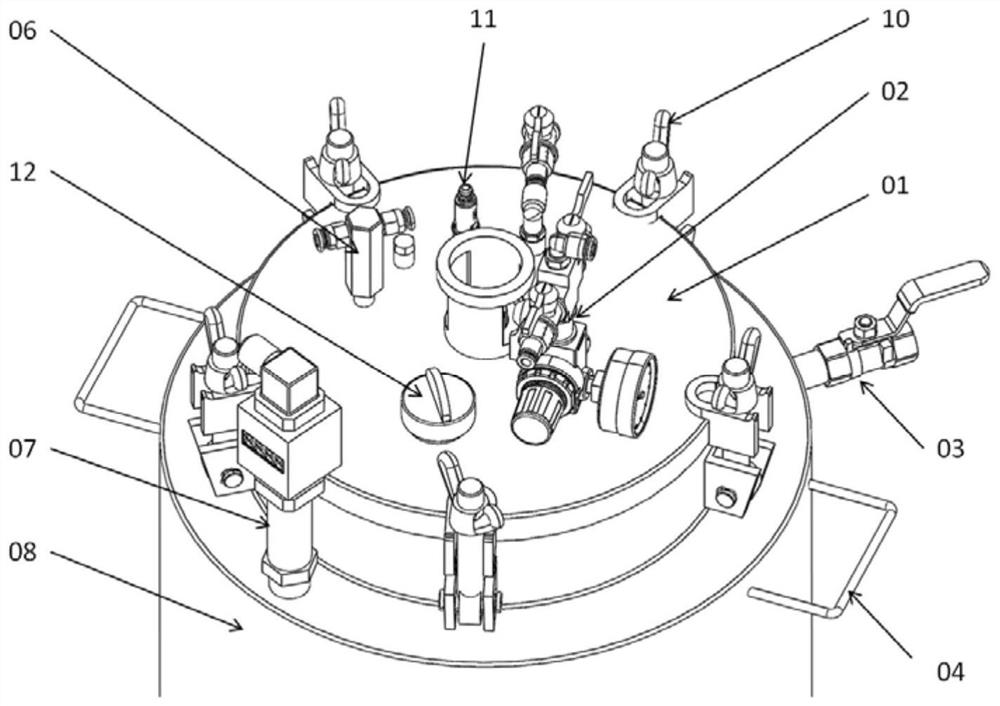

[0030] Embodiment one, such as Figure 1 to Figure 4 As shown, a paint pressure barrel that can precisely control the temperature, on the basis of the existing paint pressure barrel, divides the barrel body into an outer barrel 8 and an inner barrel 18, and the cavity between the outer barrel 8 and the inner barrel 18 is connected to the inlet The ball valve 09 and the outlet ball valve 03, and the inlet ball valve 09 is arranged on the bottom side of the outer tub 8, the outlet ball valve 03 is arranged on the top side of the outer tub 8, and the cavity part of the inner tub 18 and the outer tub 08 is filled with an external cold water or hot water circulation device, so as to This is used to adjust the temperature of the paint in the inner barrel 18. An integrated digital display temperature sensor 07 is added to the shoulder of the outer barrel 08, which can not only monitor the water temperature and display the temperature value in real time, but also transmit the temperatu...

Embodiment 2

[0032] Embodiment two, such as Figure 5 to Figure 7 As shown, a paint pressure barrel that can precisely control temperature, the pressure barrel adopts a single-layer structure, a circular spiral coil 25 is added inside the barrel body 23, and the external cold water is connected through the spiral coil inlet ball valve 24 and the three-way outlet ball valve 22 Or a hot water circulation device, the paint is directly filled in the barrel, and the circulating water flow in the circular spiral coil 25 is utilized to regulate the temperature of the paint. A small integrated digital display temperature sensor 21 is added to the three-way outlet ball valve 22 to monitor the water flow temperature in real time and display the temperature value, and at the same time transmit the temperature signal to the external temperature control device, so as to realize automatic monitoring and real-time accurate automatic adjustment of the water temperature. The paint temperature is kept withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com