High-pressure-resistant visual window suitable for optical measurement of oil sprayer with wide spraying hole included angle

An optical measurement and fuel injector technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of wide nozzle angle fuel injector measurement, constant volume bomb window area is limited, and the strength is difficult to obtain Guarantee and other issues, to achieve the effect of simple structure, good adaptability and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

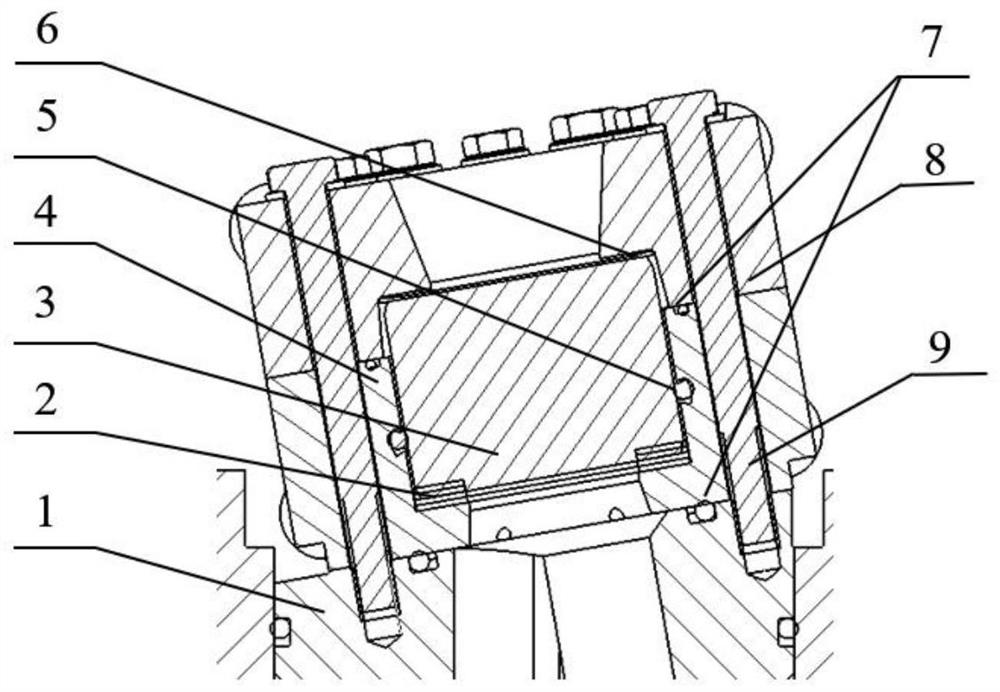

[0042] Specific implementation mode one: see Figure 1-7 This embodiment will be described. In order to continuously withstand the test conditions of high temperature and high pressure, the size of the quartz glass window of the constant volume bomb is very limited. The side window of the traditional constant volume bomb is arranged parallel to the axis of the bomb body, so the adjustable angle range of the incident light is very small, and it is difficult to adapt to wide spraying. Test conditions for angled orifice injectors.

[0043] In view of the above problems, the present invention proposes a high-pressure-resistant visual window design suitable for porous injectors with a wide range of nozzle angles. The constant-volume bombs have different installation methods according to experimental needs. Here, the PLIF method is used to measure Take the installation method including a main window and a side window as an example, and describe the assembly relationship of the cons...

Embodiment 1

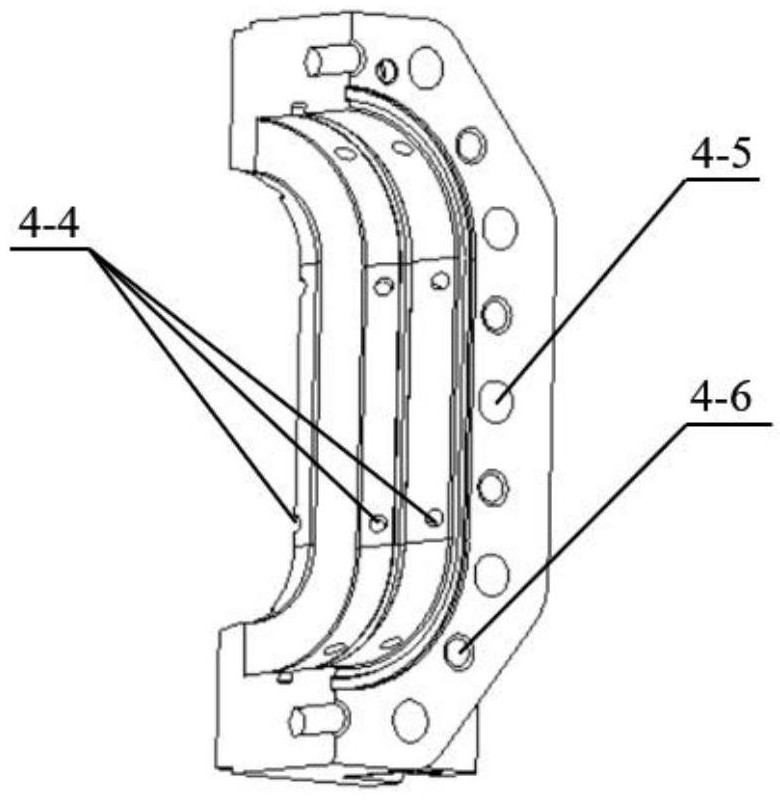

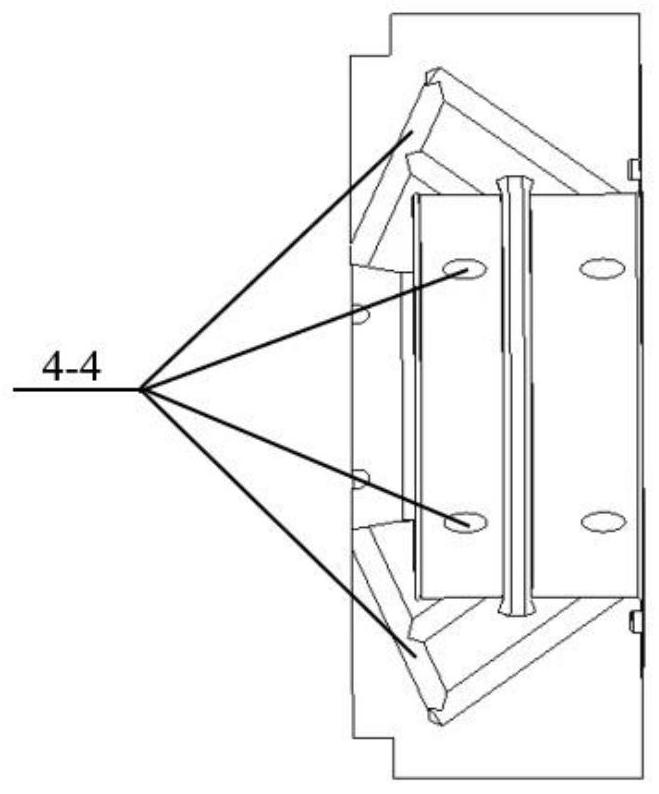

[0054] The constant volume projectile body 1 is a hexahedral structure, the bottom surface is connected to the base, the top surface is connected to the intake and exhaust and preheating devices, and the side is connected to the corresponding window and fuel injector according to the experimental needs. The sleeve 4-1 and the end cover 8-1 of the side view window are connected to the constant volume bomb body 1 through 10 connecting bolts 9; Ring 7-1 is sealed, the stepped surface inside the sleeve 4-1 cooperates with the quartz glass window 3-1 through the graphite gasket 2-1, and the centering O-ring 5-1 is used for the radial positioning of the quartz glass window 3-1 , to ensure that the quartz glass window 3-1 is always in the central position of the sleeve 4-1, the entire side of the quartz glass window 3-1 communicates with the cavity of the constant volume bomb through the bypass hole 4-4 provided on the sleeve, Used to balance the air pressure on the bottom and side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com