Method for detecting concentration of hydrochloric acid in iron ion-containing pickling waste liquid

A technology of pickling waste liquid and hydrochloric acid concentration, which is applied in the detection field, can solve the problems of affecting the end point indication of bromocresol green, the inability to specify the reaction end point, and large titration errors, so as to reduce the damage to the body and avoid excessive addition , the effect of reducing the discriminant error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A kind of detection method of hydrochloric acid concentration of pickling waste liquid containing iron ion

[0035] A method for detecting the concentration of hydrochloric acid in waste pickling liquid containing iron ions, characterized in that the waste pickling liquid containing iron ions has a mass concentration of hydrochloric acid of 10-20%. The method for measuring the mass concentration of hydrochloric acid in the waste pickling liquid containing iron ions is to add a certain amount of iron powder into the waste acid, and according to the quality of the reaction of the iron powder, it is inferred that the concentration of the waste acid is between 10-20%.

[0036] The invention discloses a method for detecting the concentration of hydrochloric acid in pickling waste liquid containing iron ions. The indicator used is ethyl violet, and the ethyl violet changes from blue to purple at the end of titration.

[0037] A method for detecting the concentra...

Embodiment 2

[0080] Embodiment 2: A kind of detection method of the hydrochloric acid concentration of pickling waste liquid containing iron ion

[0081] When there is no masking agent, measure the concentration of hydrochloric acid in the simulated solution of pickling waste liquor.

[0082] Weigh a sample of solution C within the range of 0.6-0.65g, accurate to 0.0002g, place it in a 250mL conical flask, and use a pipette to transfer 25ml of distilled water to dilute and dissolve the sample, shake well and add 2 drops of ethyl violet indicator , with a calibrated NaOH standard solution (C NaOH =0.096mol / L) for titration. Calculate the concentration of hydrochloric acid according to formula (1.2), select 3 samples and take the average value to obtain the concentration of hydrochloric acid of hydrochloric acid solution C.

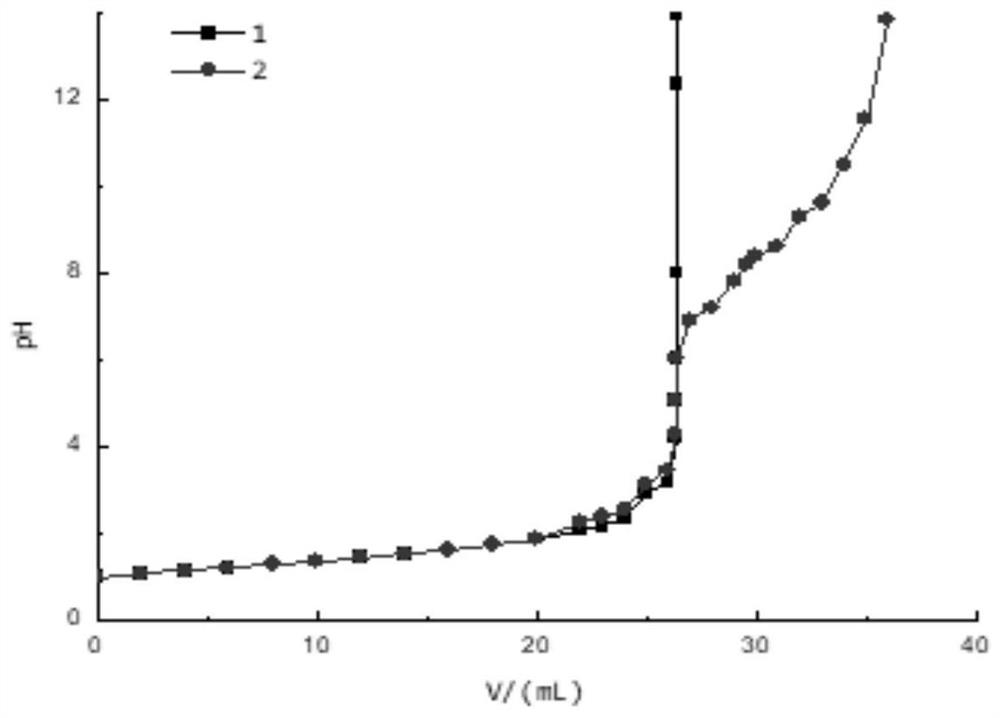

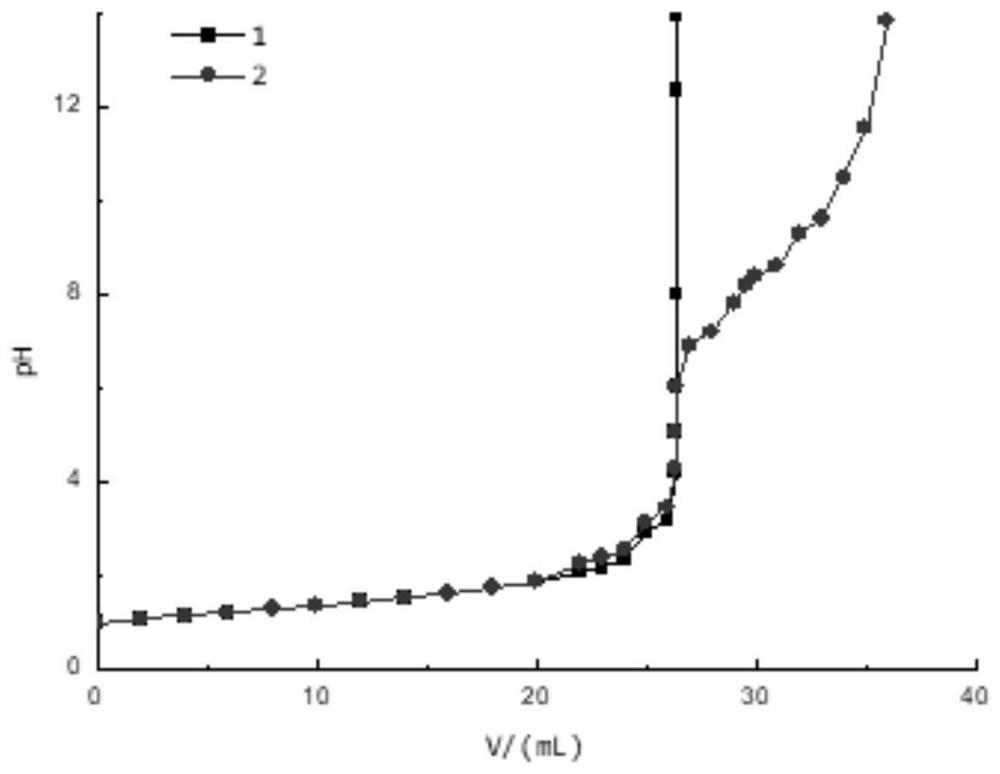

[0083] The result is as figure 2 As shown, curve 1 among the figure is a standard curve, and curve 2 represents the titration curve of measuring pickling waste simu...

Embodiment 3

[0086] Embodiment 3: A kind of detection method of the hydrochloric acid concentration of pickling waste liquid containing iron ion

[0087] Determination of hydrochloric acid concentration in simulated solution of pickling waste liquor after adding masking agent

[0088] With ethyl violet as indicator, NH 4 SCN and NaF were used as masking agents to determine the concentration of hydrochloric acid in solution C.

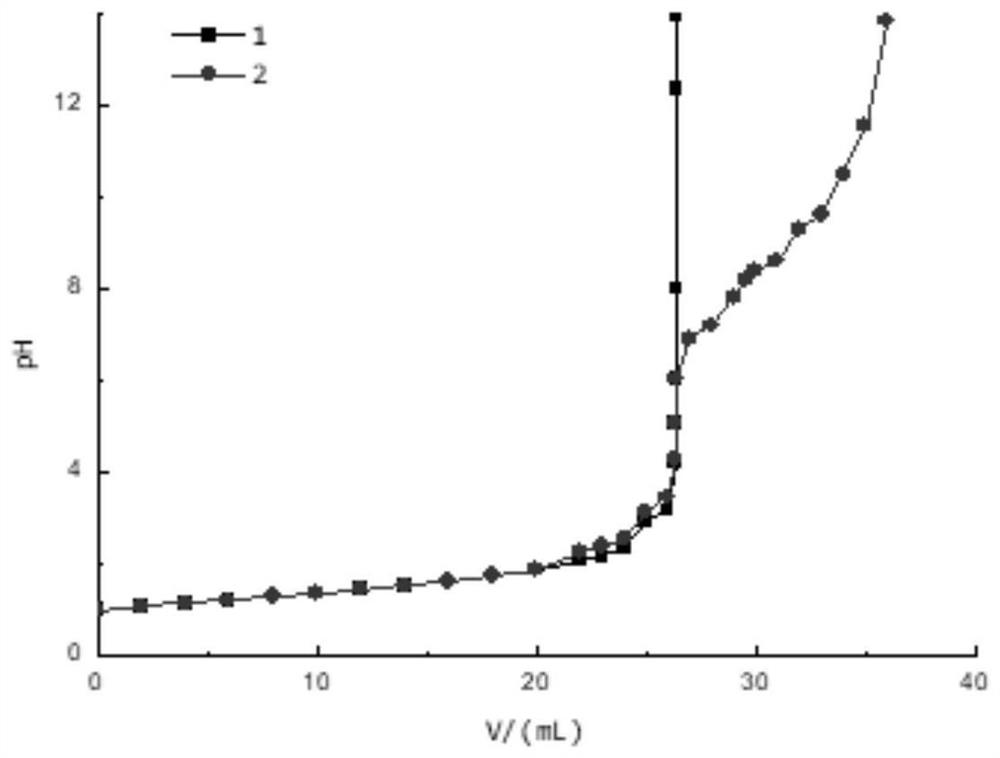

[0089] Weigh a sample of solution C within the range of 0.6-0.65g, accurate to 0.0002g, place it in a 250mL conical flask, transfer 25ml of distilled water with a pipette to dilute and dissolve the sample, add 0.1gNH 4 Shake well after SCN and 0.05gNaF, add 2 drops of ethyl violet indicator, and use the calibrated NaOH standard solution (C NaOH =0.096mol / L) for titration. Calculate the concentration of hydrochloric acid according to the formula (1.2), select 3 stable data and take the average value to obtain the concentration of hydrochloric acid in the simulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com