A resource separation and recovery device for waste reinforced concrete slab walls

A reinforced concrete, separation and recycling technology, applied in the direction of solid separation, magnetic separation, cleaning method using liquid, etc., can solve the problems of low separation efficiency of concrete and steel bar, high labor cost, steel bar labor, etc., to reduce labor cost, use Flexibility and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

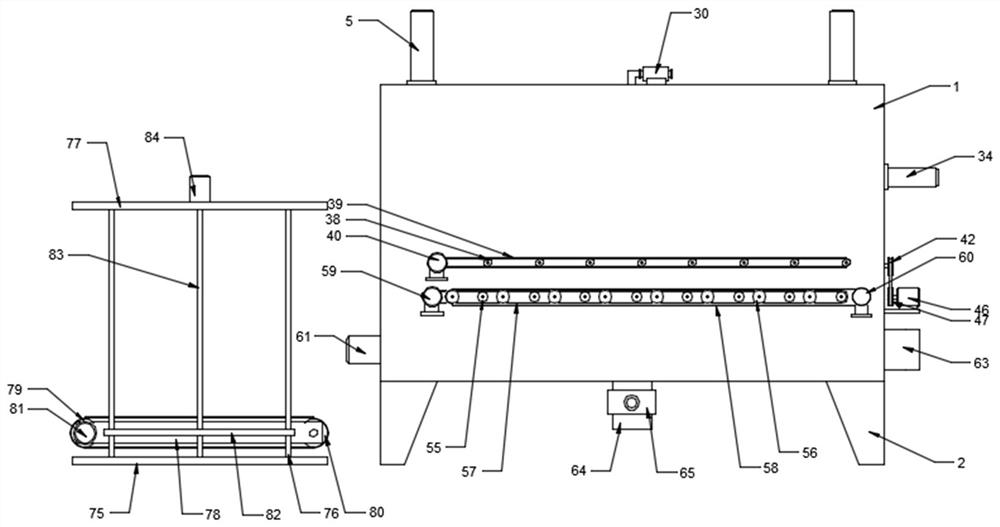

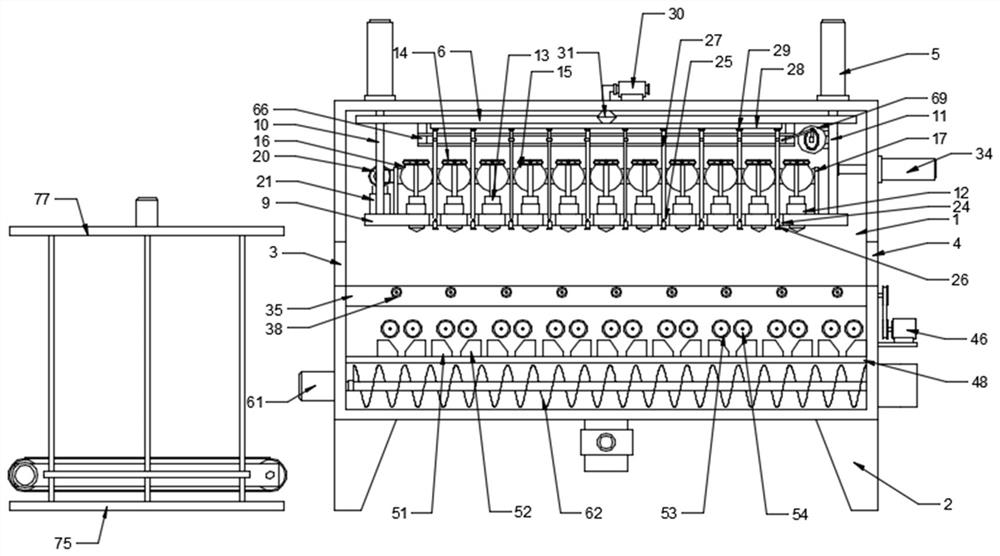

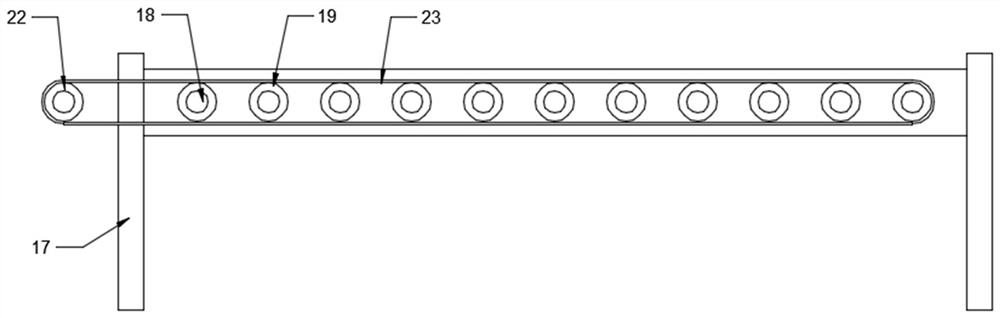

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] combined with figure 1 And attached figure 2 The left side of the box body 1 is provided with a board feeding device, the board feeding device includes a base plate 75, and the four corners of the upper end surface of the base plate 75 are provided with uprights 76, the upper end of the upright rod 76 is provided with a top plate 77, and the top of the base plate 75 is provided with a frame three 78, The left and right ends of the frame body three 78 are rotatably connected with a driving belt roller 79 and a driven belt roller 80, the driving belt roller 79 and the driven belt roller 80 are provided with conveyor belts, and the front left end of the frame body three 78 is provided with a motor eight 81, The output end of the motor eight 81 is connected with the driving belt roller 79, and the front and back sides of the frame body three 78 are all p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com