Full-automatic round pipe cutting machine

A cutting machine, fully automatic technology, used in pipe shearing devices, shearing devices, accessories of shearing machines, etc., can solve problems affecting work efficiency, cutting size errors, safety hazards, etc., to achieve agile action and accurate cutting length. , the effect of reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

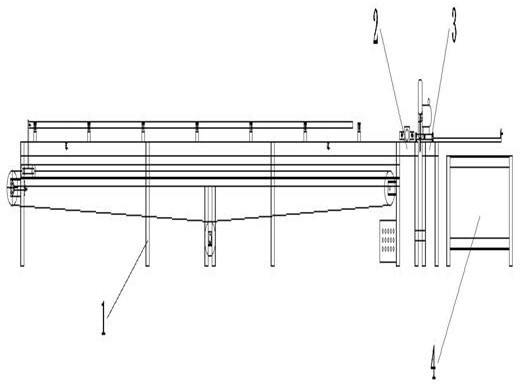

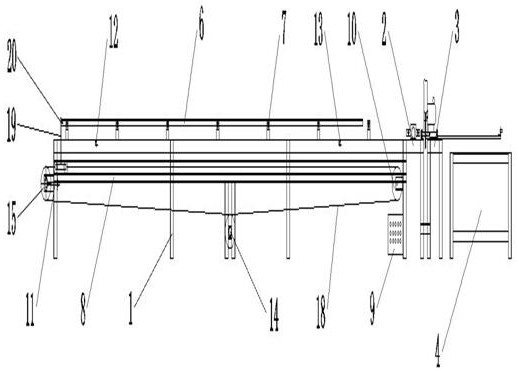

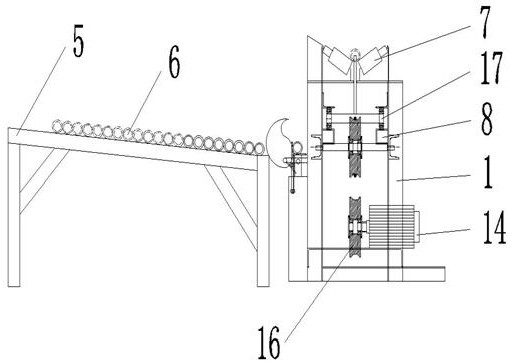

[0022] Such as Figure 1-7 As shown, a fully automatic round pipe cutting machine includes a transmission frame 1, a locking frame 2, a cutting frame 3, a storage frame 4 and a feeding frame 5, and the transmission frame 1 is provided with a feeding roller 7 and a slideway 8 , PLC control cabinet 9, right wire rope pulley 10, adjusting screw 11, material detection switch 12, no material detection switch 13 and stepper motor 14, feeding idlers 7 are installed and fixed in a V-shaped distribution equidistant on the top of the transmission frame 1, sliding The channel 8 is welded symmetrically above the inner side of the transmission frame 1, the PLC control cabinet 9 is installed and fixed under the right end of the transmission frame 1 through screws, the right wire ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap