A kind of drying equipment for plastic particles scattered up and down

A technology for drying equipment and plastic particles, which is applied in the field of upper and lower scattered plastic particle drying equipment, can solve the problems of uneven drying of products, excessive drying and incomplete drying of plastic particles, etc., so as to avoid uneven drying. , Improve the drying effect and promote the effect of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

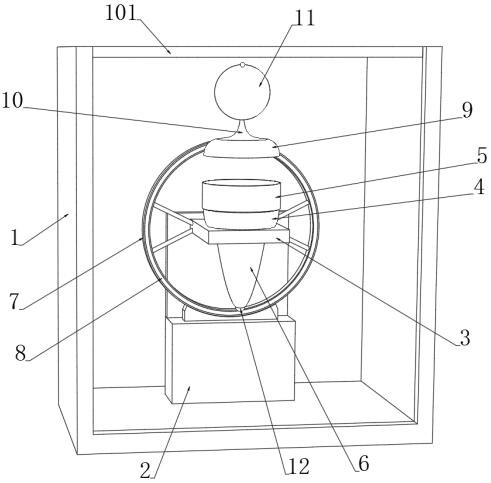

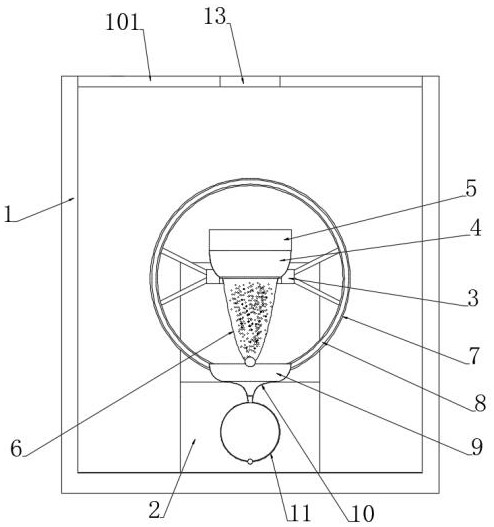

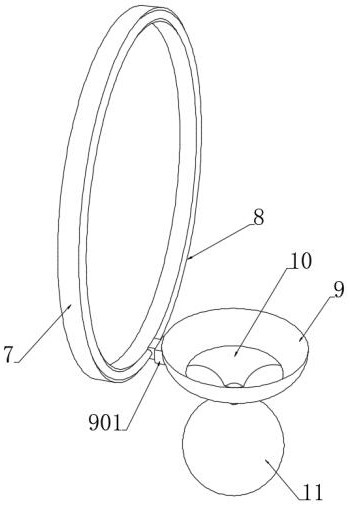

[0041] see Figure 1-2 , a drying equipment for plastic particles scattered up and down, including a drying box 1, a supporting seat 2 is installed on the inner bottom of the drying box 1, and an outwardly extending connecting plate 3 is fixedly connected to the side wall of the upper end of the supporting seat 2, The connecting plate 3 is fixedly set with a blanking hopper 4, and the bottom end of the blanking hopper 4 is connected with an elastic bag 6, and the inner bottom of the connecting plate 3 is provided with a blanking cavity corresponding to the position of the elastic bag 6, and the elastic bag 6 is A funnel-shaped structure with a wide top and a narrow bottom, and its upper end is an open structure, and the lower end is a closed structure. The elastic bag 6 is made of a highly elastic and breathable fiber material. The cavity is connected with the material guide hole 401 provided, the bottom end of the elastic bag 6 is connected with a magnetic ball 12, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com