Hoisting device for coal mine roadway

A technology for lifting devices and coal mine roadways, which is applied in the direction of hoisting devices, tunnels, shaft equipment, etc., can solve the problems of increasing the danger of workers' arches, increasing the working intensity of workers, and the inconvenience of fitting lifting devices, etc. Achieve the effect of improving convenience, reducing labor intensity and avoiding deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

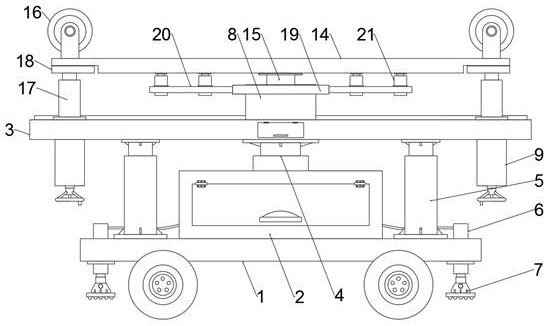

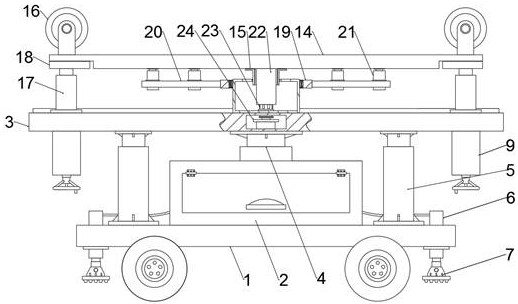

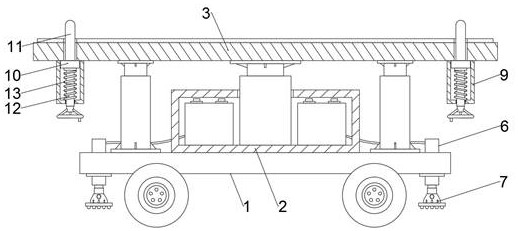

[0022] Example: see Figure 1-5 , a lifting device for coal mine roadways, including a flatbed trailer 1, a fixed box 2 arranged in the middle of the top surface of the flatbed trailer 1, and a bearing plate 3 horizontally arranged above the fixed box 2, and a layer of anti-slip is laid on the top surface of the bearing plate 3 An electric push cylinder 4 is provided inside the fixed box 2, and the telescopic end of the electric push cylinder 4 penetrates the outside of the fixed box 2 and is fixedly connected to the carrying plate 3, and the four corners of the bottom surface of the carrying plate 3 and the top surface of the flatbed trailer 1 are evenly spaced. A stable telescopic rod 5 is fixedly connected; the middle part of the front end of the top surface of the load plate 3 is fixedly connected with a cylindrical box 8, and the upper part of the cylindrical box 8 is provided with a jacking mechanism for raising the roadway arch; the four corners of the top surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com