Coal mine electromechanical equipment

A technology of electromechanical equipment and coal mines, applied in mining equipment, mining equipment, safety devices, etc., can solve problems such as slippery coal mine ground, endangering the safety of the equipment itself or surrounding personnel, and position deviation, so as to prolong the service life and avoid corrosion , Increase the effect of exercise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

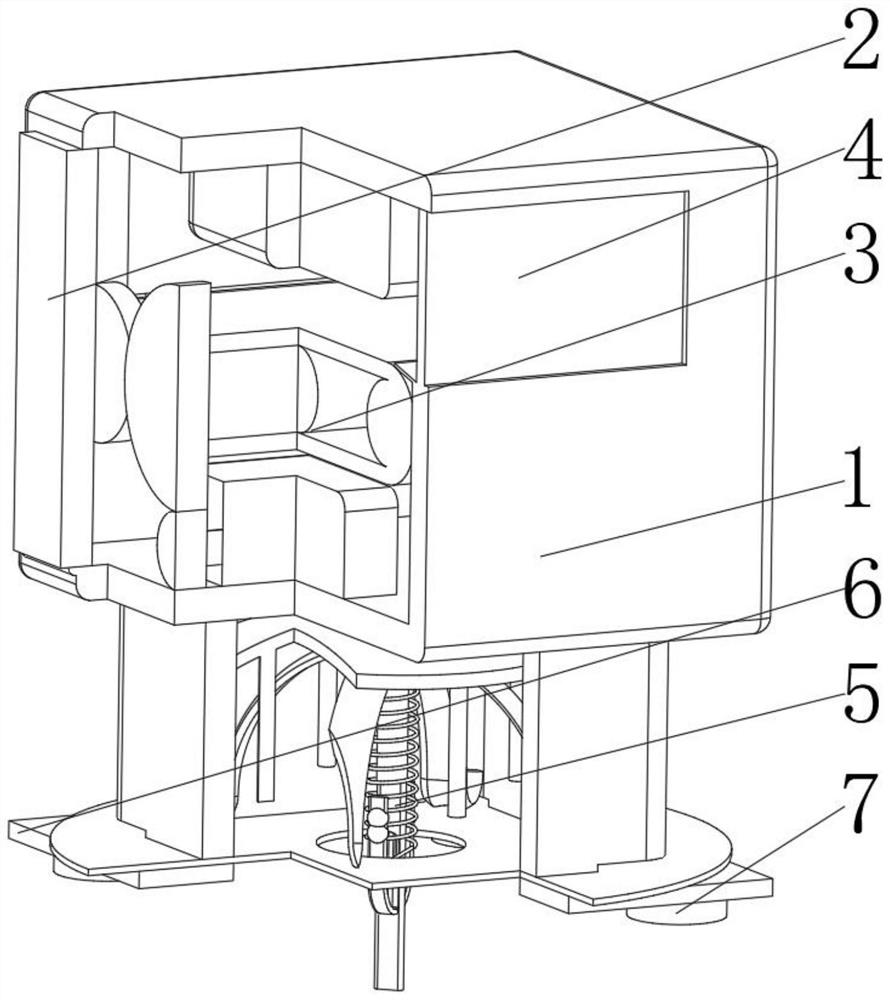

[0033] See figure 1 , 2 , 4, the present invention provides a technical solution: a coal mine mechanical and electrical equipment, including:

[0034] Equipment Box 1, the equipment box 1 has a casing, and a box door 2 mounted on the left side of the casing, and is disposed in the belt device 3 at the bottom of the casing, and the entrance and exit 4 of the front side of the box and the top of the back surface;

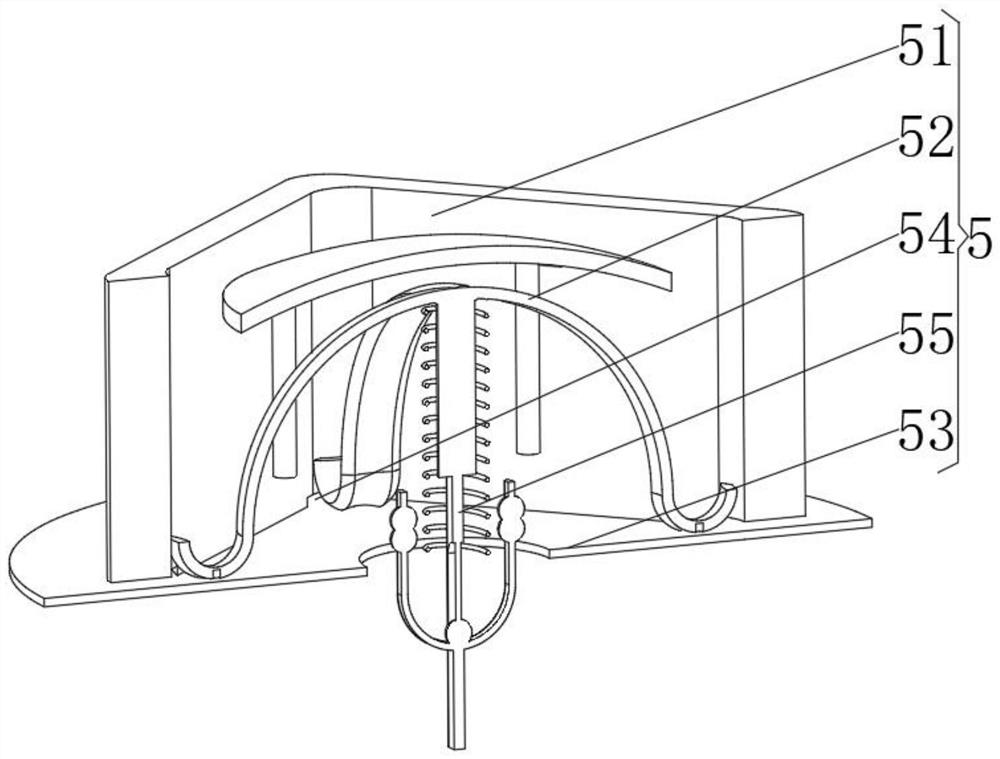

[0035] Moisture mechanism 5, the moisture-proof mechanism 5 is mounted at the bottom of the box, and the guide water plate 6 mounted at the bottom of the moisture-proof mechanism 5, and is fixed to the non-slip foot 7 at the bottom of the guide flow plate 6, and the coal mine is used by the guide water plate 6 The moisture of the ground dry evaporation is collected, avoiding the water generated in the drawing water plate 6 causes moisture to the coal mine floor, and after the dry evaporation of the moisture is collected, it will not cause environmental wet heat, effective...

Embodiment 2

[0042] See Figure 1-4 Based on the example one, the present invention provides a technical solution:

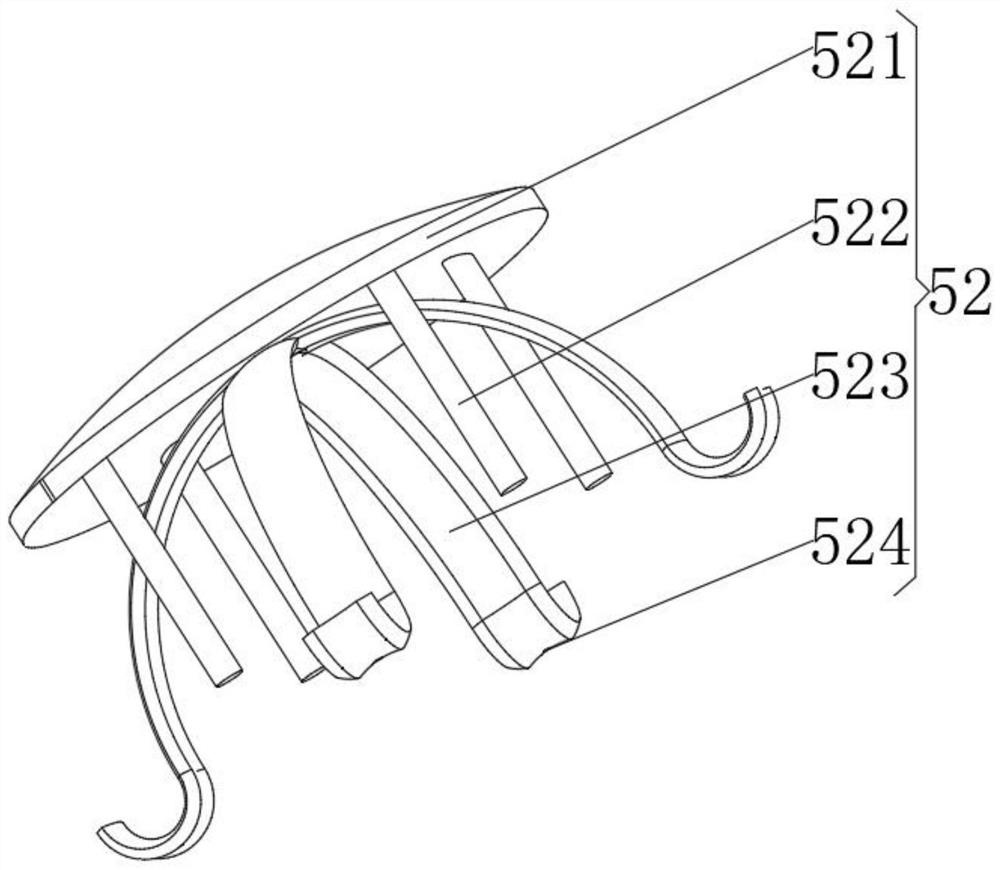

[0043] The flow guide 52 includes an arcuate top plate 521, as well as a guide post 522 mounted at the bottom of the curved top plate 521, and is disposed between the arcuate circuit plate 523 between the guide post 522, and is opened in an arcuate The through hole 524 of the top and bottom positions. Through the spherical surface design of the curved top plate 521, the motion impact generation generated by the equipment box 1 is uniformly dispersed, and the bottom member is protected to avoid damage to the bottom member, and the curved top plate 521 itself can be pair The evaporated moisture is conducted, drained to the fluid post 522 to achieve a condensed and flow of moisture.

[0044] The curved multi-fluid plate 523 is mounted at the corner of the moisture-proof box 51, and the through hole 524 penetrates the arc-shaped multifunctional plate 523 and extends to the top of the...

Embodiment 3

[0047] See figure 1 , 2 , 4, 5, on the basis of Examples One and Example 2, the present invention provides a technical solution: the sensing mechanism 555 includes a middle column A1, a magnetic ball A2 mounted at the bottom of the middle column A1, and mounted in magnet A2 The U-type vibrating bar A3 at the bottom of the outer surface is provided with a magnet A4 opposite to the magnetic pole of the magnetic ball A2 by the U-shaped rod A3 away from the magnetic ball A2. Using the vibration generated during operation, the U-shaped rod A3 is designed due to its own tuning, and the shock is formed, and the shift of the magnet A4 generates the position, forming a change in the magnetic field, and the electromagnetic sensor should cause the heating coil 551 to generate current, realize Energy auxiliary replenishment.

[0048] The middle column A1 is mounted at the top of the insulation ring 554, and the magnetic ball A2 and the U-shaped rod A3 are disposed in the insulation ring 554 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com