Method for replacing pre-embedded anchor bolt of concrete tower drum

A replacement method and pre-embedded anchor bolt technology, which is applied to the assembly of wind turbines, the configuration of installation/support of wind turbines, and wind power generation. Cost-effective, quick replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

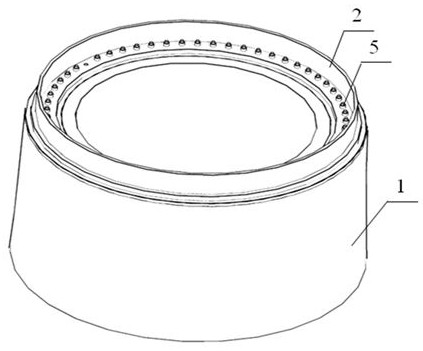

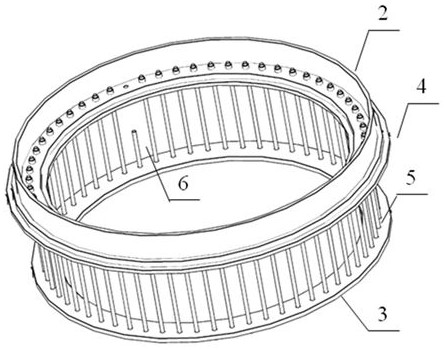

[0044] A certain pre-embedded bolt 5 in the concrete tube section 1 is broken. The diameter of the pre-embedded bolt 5 is 48 mm, and the diameter of the reserved hole for installing the pre-embedded bolt 5 is 52 mm. A technical bolt removal tool cannot take out the embedded bolt lower section 6.

[0045] The concrete operation of adopting the present invention to remove the embedded bolt lower section 6 and install new embedded bolts 5 is as follows:

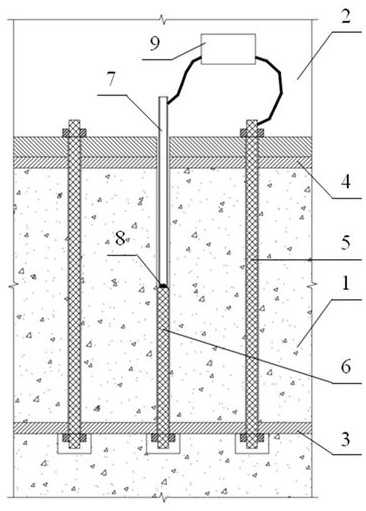

[0046]Step 1: After taking out the upper section of the broken embedded bolt, take a steel pipe with a diameter of 42mm, a wall thickness of 3mm, and a length of 1.2m as the conductive pipe 7, and insert the conductive pipe 7 into the reserved hole for installing the embedded bolt In this process, the lower end of the conductive pipe 7 is in contact with the top of the lower section 6 of the embedded bolt, and the upper end of the conductive pipe 7 extends to the top of the concrete cylinder section 1, and is located at about 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com