Method for measuring pressure of turbine chamber of marine gas turbine

A gas turbine and chamber pressure technology, which is used in gas turbine engine testing, jet engine testing, measuring devices, etc., can solve the problems of wide dynamic range of measurement parameters and harsh measurement environment, and achieve reasonable and implementable technical testing solutions. Strong, survival-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

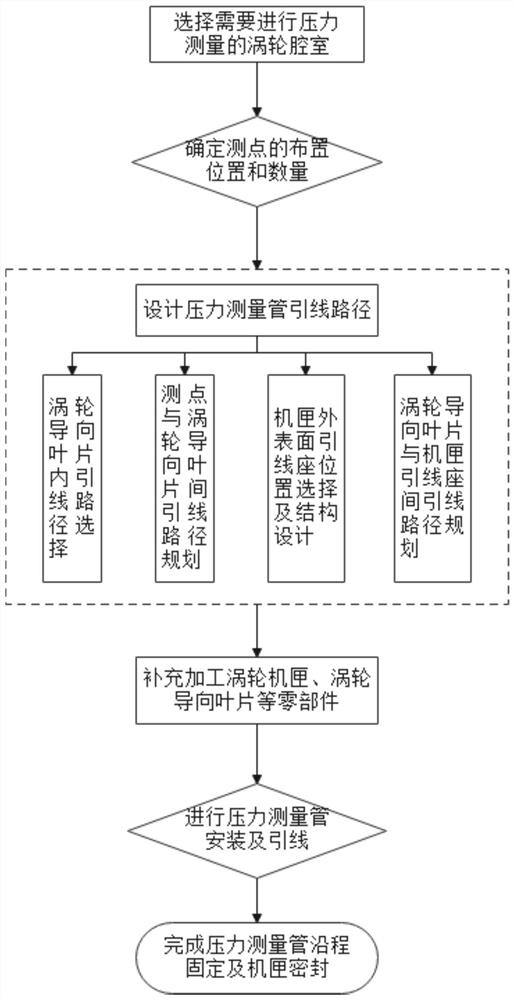

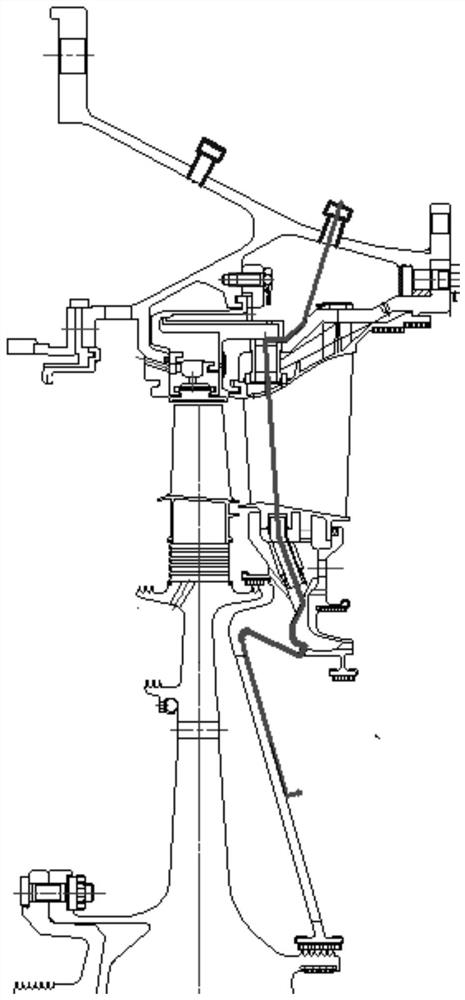

[0026] combine Figure 1-2 , the present invention is realized through the following steps:

[0027] Step 1: Select the turbine chamber that needs to be measured for pressure;

[0028] Step 2: Determine the location and quantity of the measuring points in the turbine chamber to be tested. Considering the survival rate of the measuring points, and ensuring the repeatability and validity of data measurement, the number of measuring points in the same chamber is generally set to three or more, and the measuring positions of the turbine chamber where different measuring points are located are exactly the same, but the angular position different.

[0029] Step 3: Design the lead wire path of the pressure measurement tube. According to the actual installation sequence of the pressure measurement pipeline, design the lead wire path of the pressure measurement tube. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com