Universal intelligent operation and maintenance system and method for flexible variable maintenance process of high-speed train

A technology for high-speed trains and operation and maintenance systems, applied in data processing applications, railway vehicle testing, instruments, etc., can solve the problems of non-flowing parts information, single maintenance categories, and difficult expansion of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

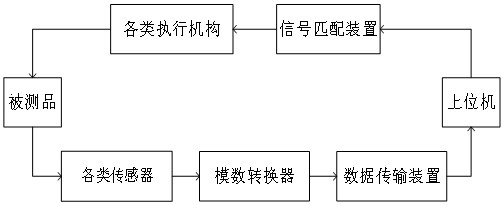

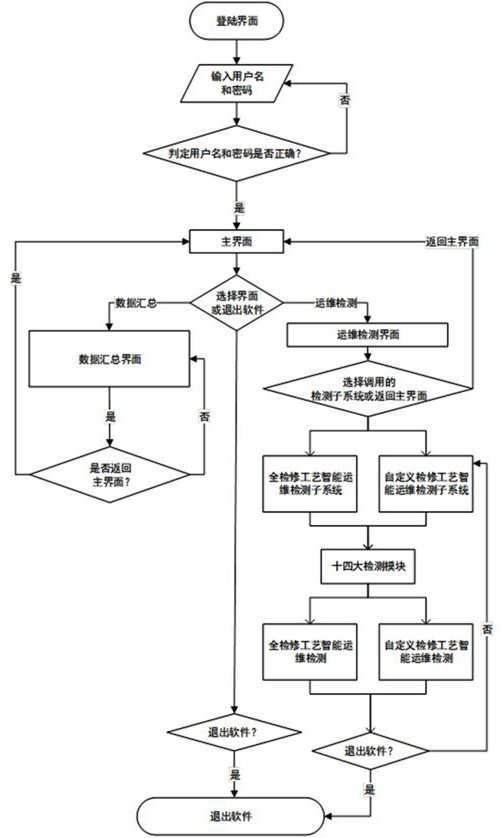

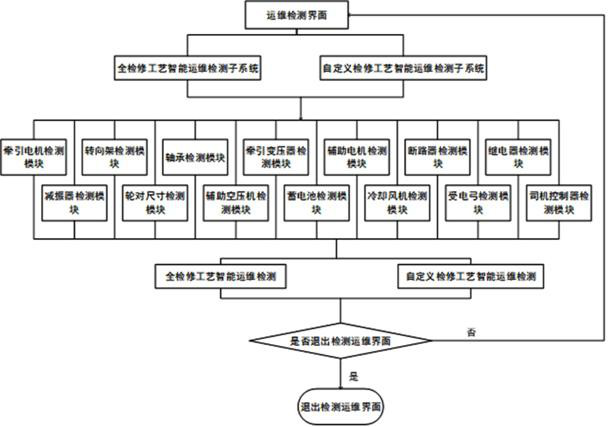

[0058] This embodiment provides a general-purpose intelligent operation and maintenance system for flexible and variable maintenance processes of high-speed trains, including an intelligent operation and maintenance detection subsystem for a full maintenance process, an intelligent operation and maintenance detection subsystem for a custom maintenance process; an intelligent operation and maintenance detection subsystem for a full maintenance process Including a number of established different detection modules and their corresponding conditional loop sub-modules, it is used for high-speed trains and their parts to carry out integrated intelligent operation and maintenance detection on the existing assembly line one by one according to the complete maintenance process steps: custom maintenance process intelligence The operation and maintenance detection subsystem can independently select the detection module and the conditional loop sub-module, and is used for high-speed trains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com