Damage determination method and system for curing molding of toughened composite material

A toughening composite material, curing molding technology, applied in the direction of material thermal development, force/torque/work measuring instrument, instrument, etc., can solve the problem of unpredictable material resin-pin interface area damage, difficult to grasp the curing damage evolution mechanism , the inability to accurately assess the service performance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

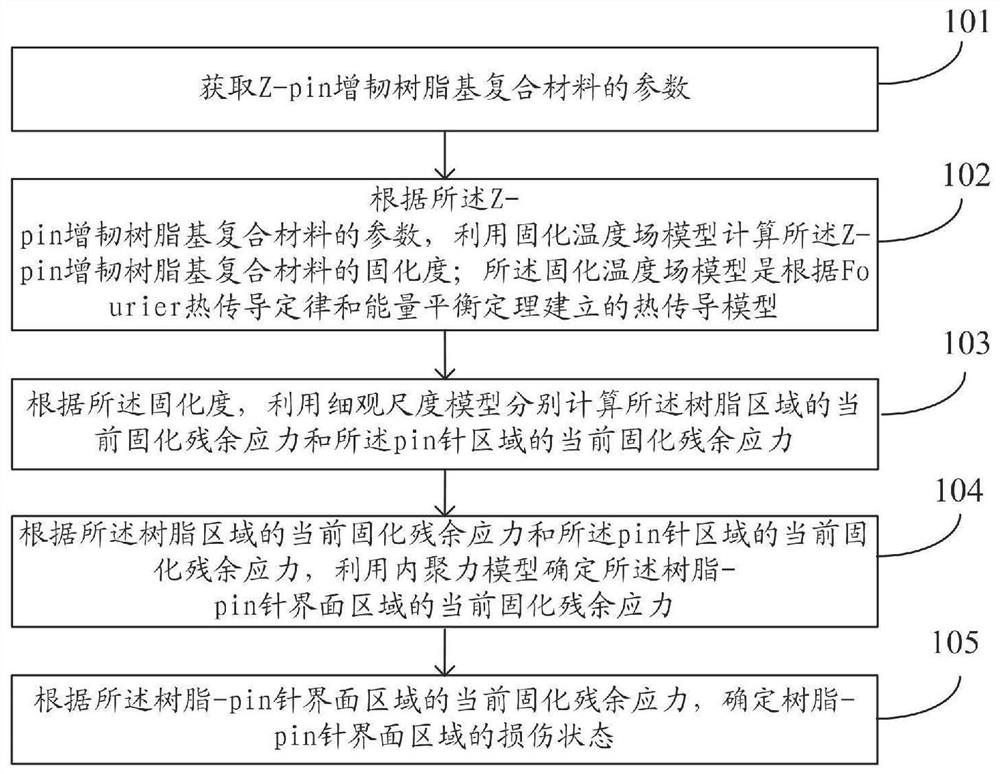

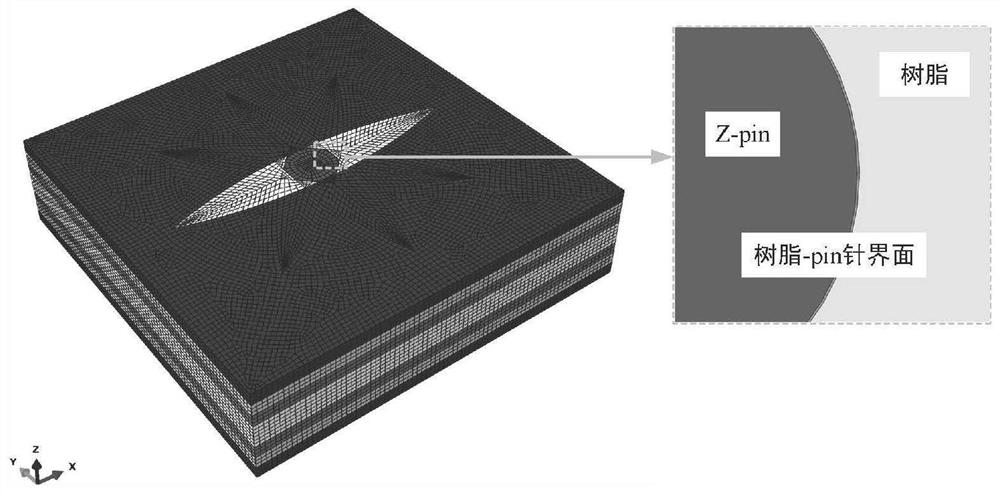

[0167] Step 1: Build as figure 2 The meso-scale model shown adopts the [0 / 45 / 90 / -45]s resin-based composite layering method, and applies a bilinear cohesion model in the resin-pin interface region;

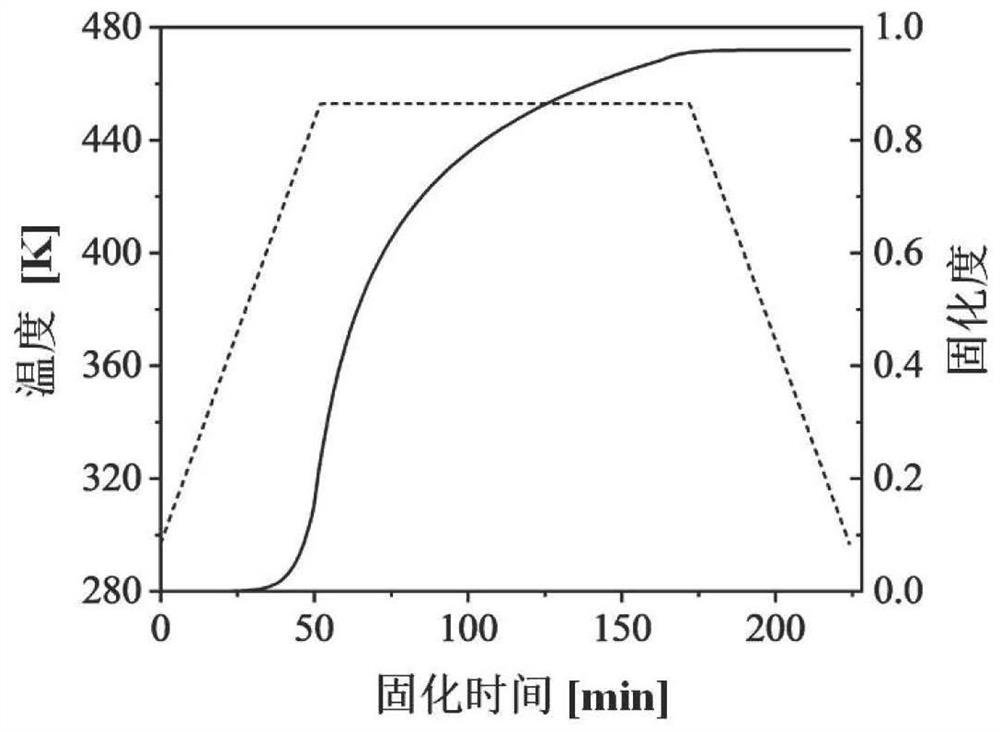

[0168] Step 2: Apply solidification molding load conditions on the mesoscale model, and solve the solidification degree and residual stress of the model. The results are as follows: image 3 , Figure 4 shown;

[0169] Step 3: Apply the obtained curing residual stress as a predefined field on the mesoscale model again, set the resin-pin interface damage criterion, and solve the resin-pin interface curing damage, the result is as follows Figure 5 shown.

[0170] According to the specific embodiments provided by the invention, the invention discloses the following technical effects:

[0171] (1) The present invention uses a numerical simulation analysis method to establish a Z-pin toughened resin-based composite material mesoscale model, a curing temperature field model, a res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com