An all-steel visible shear-type buckling-restrained brace

A buckling constraint, shear type technology, applied in building types, building components, earthquake resistance, etc., can solve problems such as failure to meet seismic design requirements, and achieve the effect of reducing stiffness and size, low self-weight, and stable shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

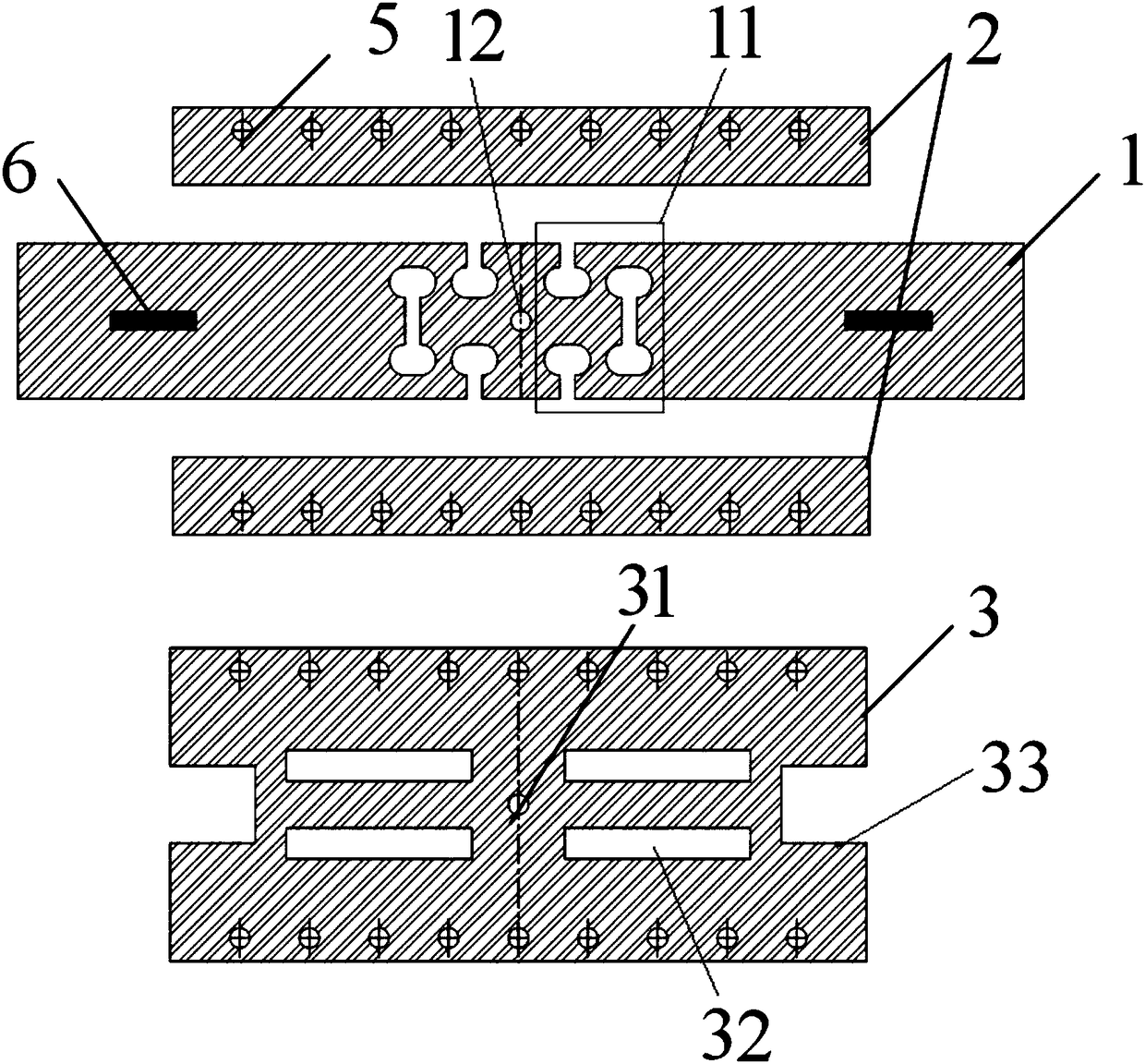

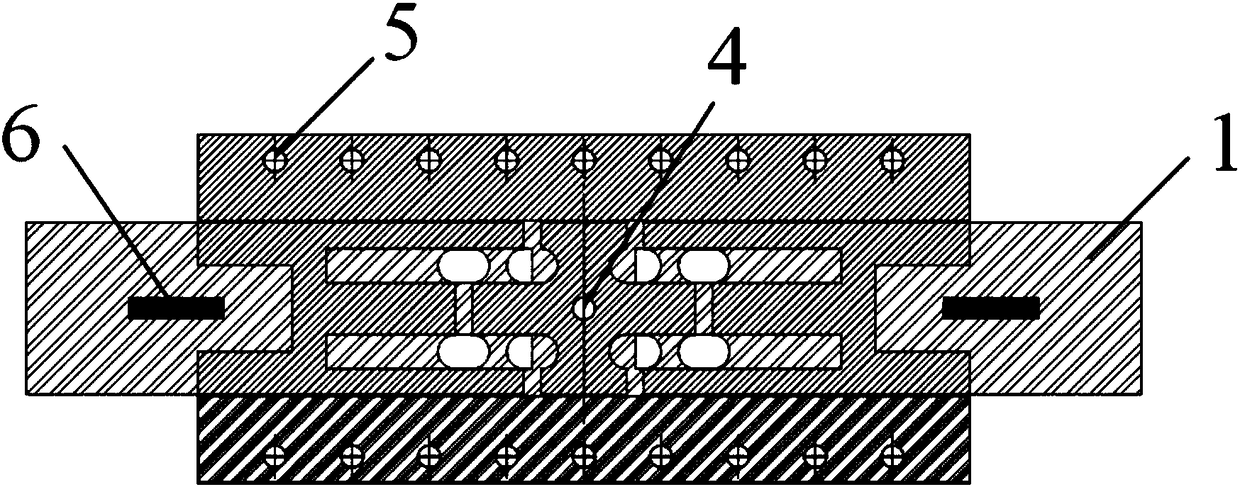

[0025] by Figure 1-3 A shear-type buckling-restrained brace is shown as an example to illustrate this patent.

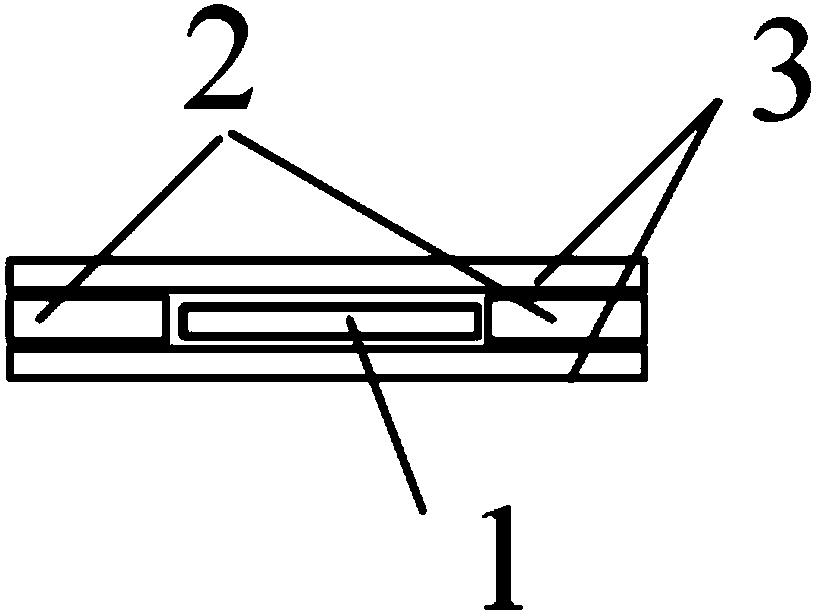

[0026] An all-steel visible shear-type buckling-restrained brace, the buckling-restricted brace includes a shear-type core material 1, a visually constrained plate 3 and a filling plate 2, two filling plates 2 are arranged on the On the left and right sides of the cut core material 1, there are two visual restraint plates 3, which are respectively arranged on the upper and lower sides of the shear core material 1 and the filler plate 2, and are fixedly connected to the filler plate 2 by bolts 5, The shearing core material 1 is fixed to the visible constraining plate 3 through anti-slip keys 4, and a plurality of shearing units 11 are arranged thereon.

[0027] The shearing core material 1 is a rectangular steel plate whose left and right shapes are symmetrical to the longitudinal axis of symmetry. The shearing units 11 are respectively arranged on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com