Textile machine and contactless measurement process

A textile machine, non-contact technology, applied in the direction of measuring devices, textiles and papermaking, deburring devices, etc., can solve complex problems and achieve the effect of improving the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

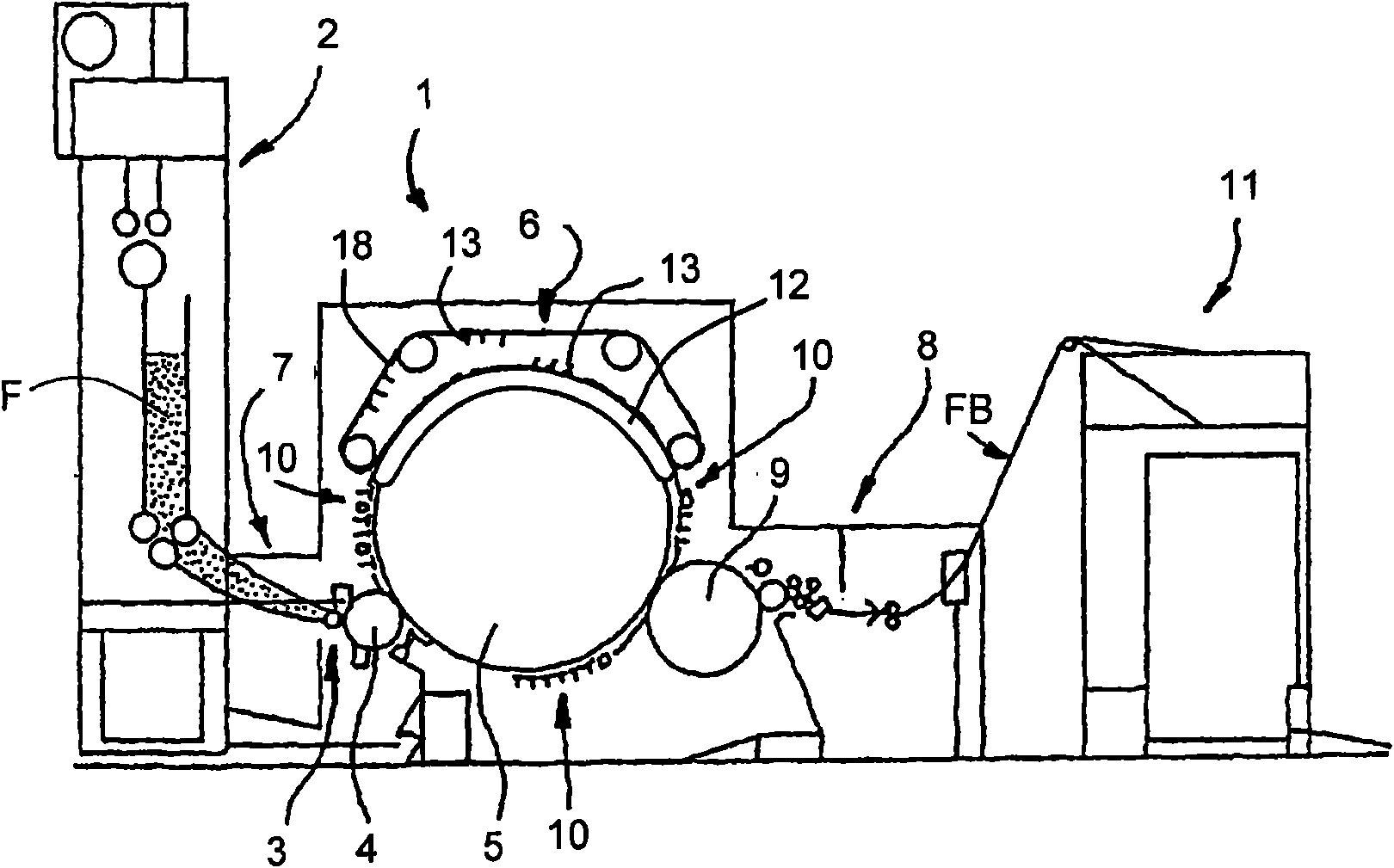

[0201] figure 1A known card 1 is shown in which batt F is conveyed from a feed box 2 to a feed roller 3 and thereafter a licker-in roller 4 . The card 1 comprises a single cylinder 5 (like a main cylinder or a so-called tenter drum) rotatably supported in a frame. The cylinder 5 works in a known manner with a revolving flat device 6, a fiber feeding system 7, in particular comprising a feed roller 3 and a licker-in roller 4, and a fiber doffing system 8, which in particular has a so-called doffer 9 . The carding elements 10 can be arranged in the pre-carding zone, post-carding zone and secondary carding zone of the card 1 . Between the revolving flat device 6 and the carding element 10 there is arranged a fiber guide element, which is not shown here in detail and will be explained in more detail below. The fiber doffing system 8 conveys the sliver FB to a sliver depositing device 11 shown schematically in the figure.

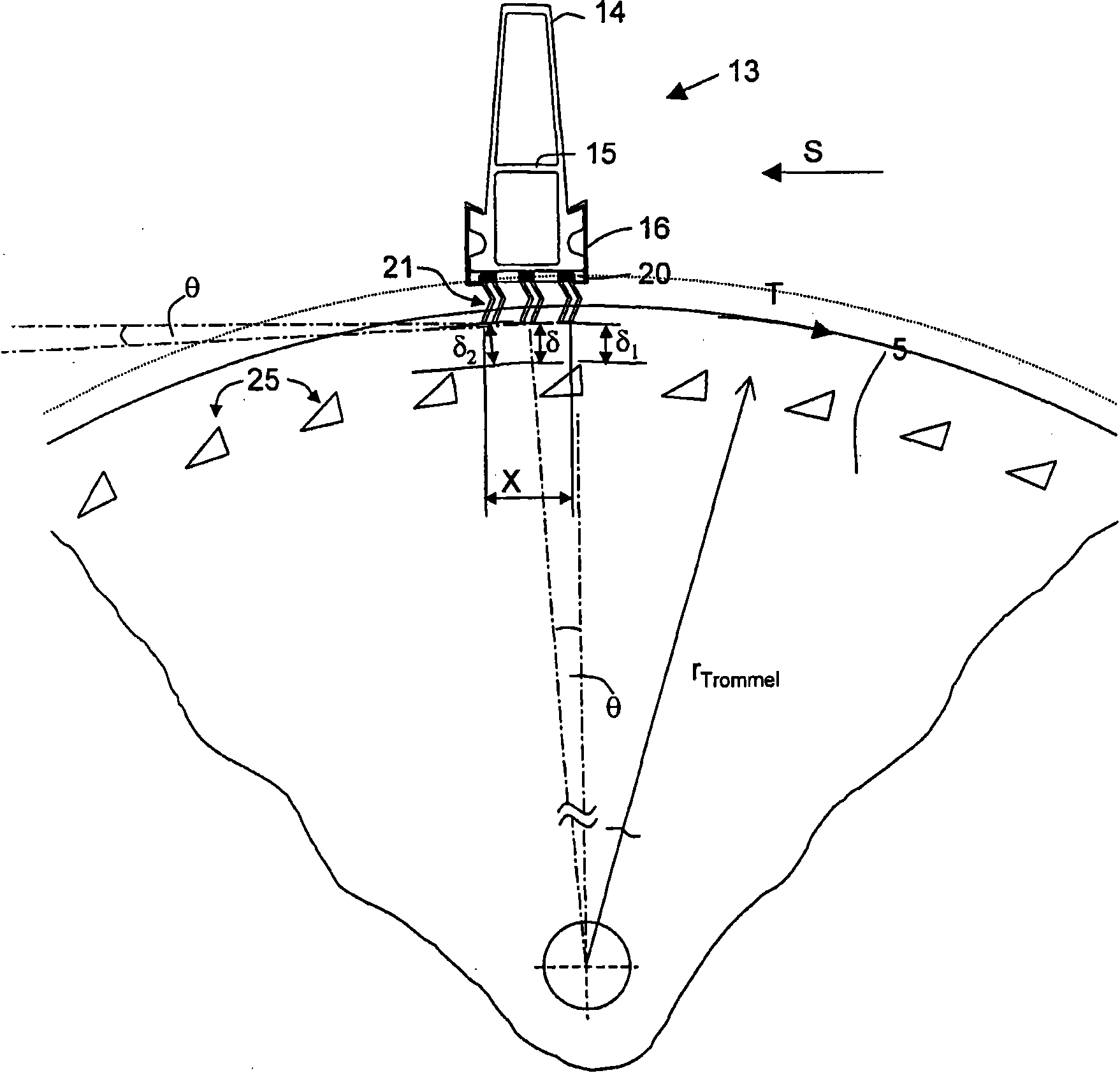

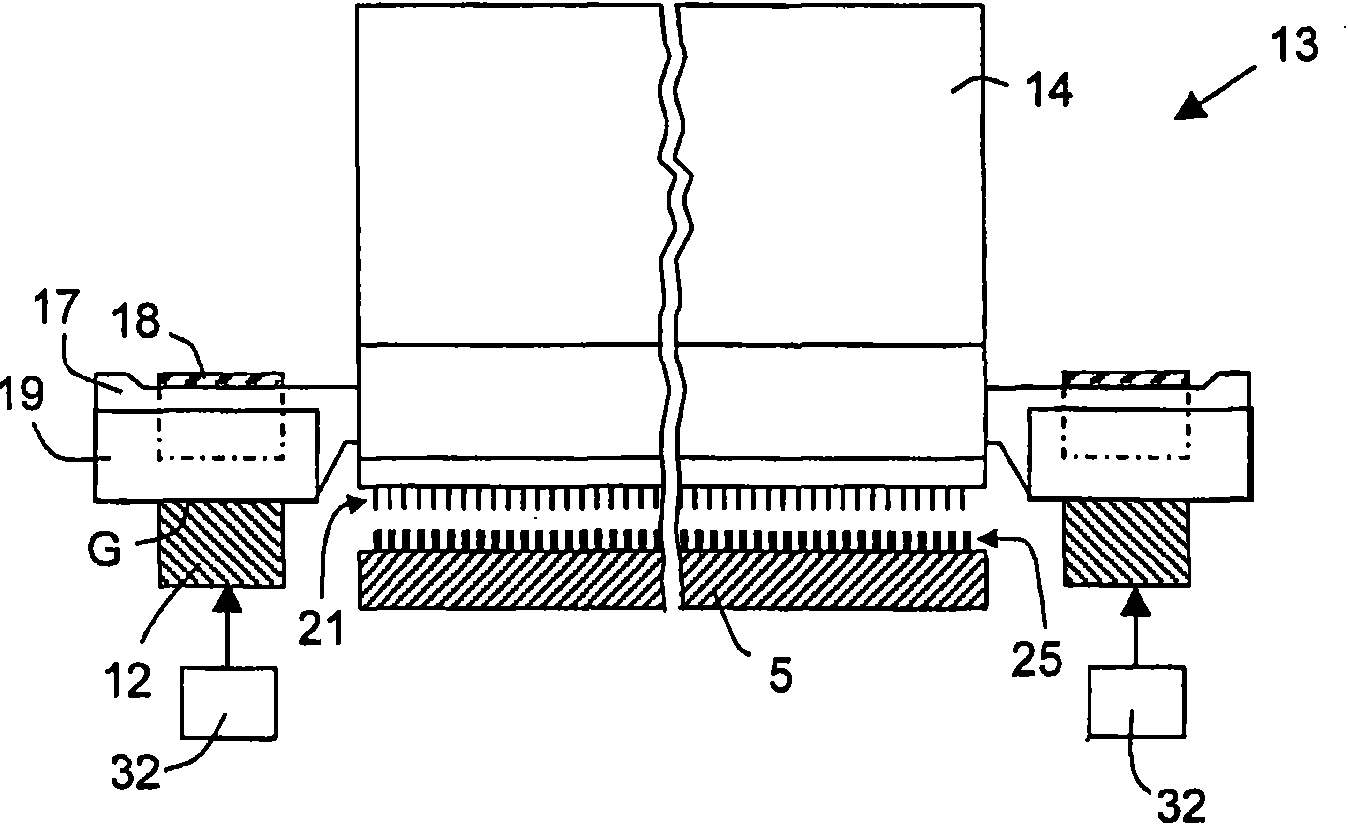

[0202] A plurality of flat rods 13 are provided on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com