Array substrate and display panel

A technology for array substrates and display panels, applied in instruments, nonlinear optics, optics, etc., can solve problems such as error reporting, misidentification, and influence on automatic optical normal detection, so as to improve production efficiency and yield, improve detection efficiency, and reduce errors. The effect of the likelihood of recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

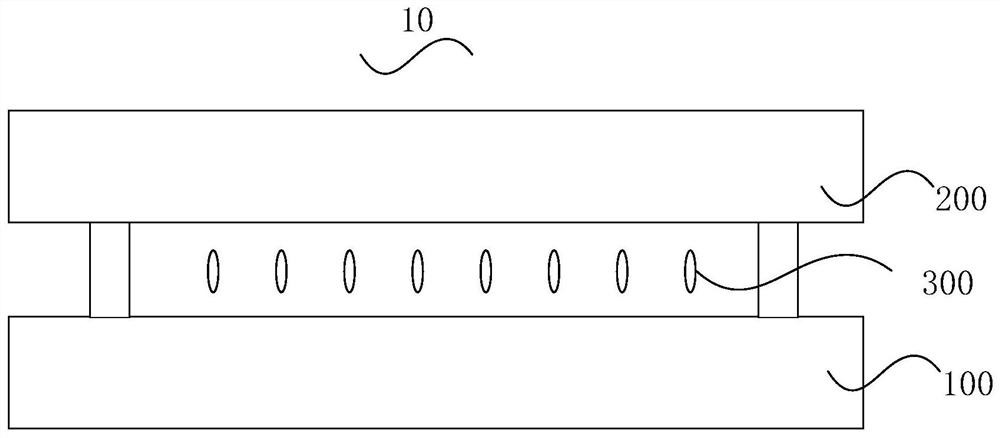

[0031] Such as figure 1 The first embodiment of the present application is shown, which discloses a display panel. The display panel 10 includes an array substrate 100 , a cell substrate 200 and a liquid crystal layer 300 disposed between the two substrates. The array substrate adopts a COA process, that is, the color filter layer is arranged on the array substrate. In order to improve the accuracy rate of the detection of the peripheral wires and reduce misjudgment, the main improvement of the present application lies in the array substrate.

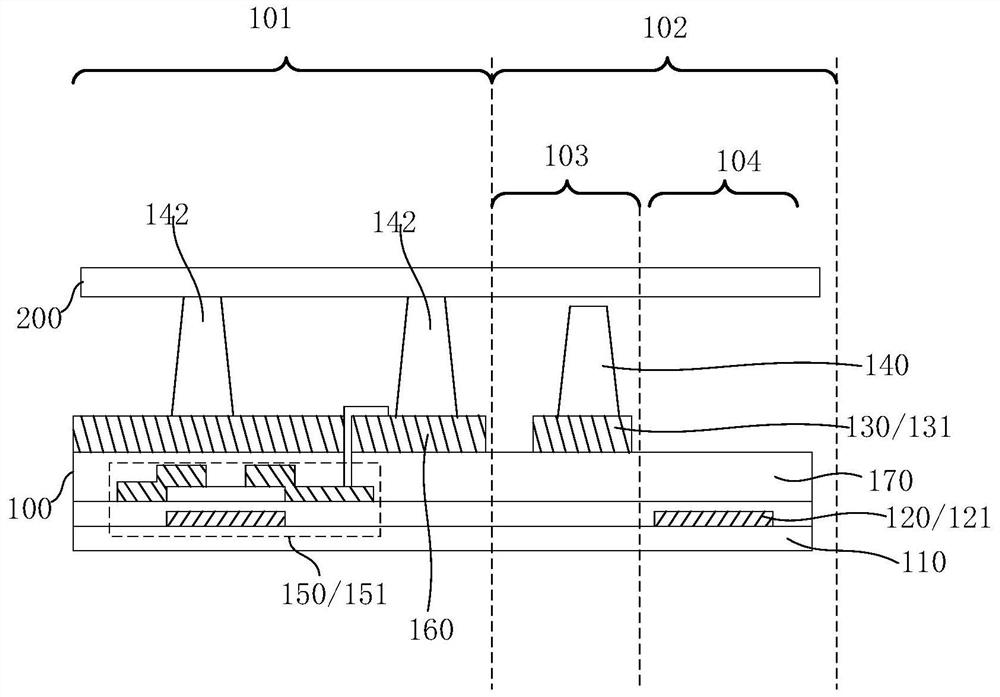

[0032] Such as figure 2 The array substrate 100 in the first embodiment is shown, the array substrate 100 is divided into a display area 101 and a non-display area 102, and the array substrate 100 corresponding to the non-display area 102 includes: a substrate 110, 110 on the peripheral wiring layer 120, the peripheral color resistance layer 130 and a plurality of first spacers 140, the peripheral color resistance layer 130 is arrang...

Embodiment 2

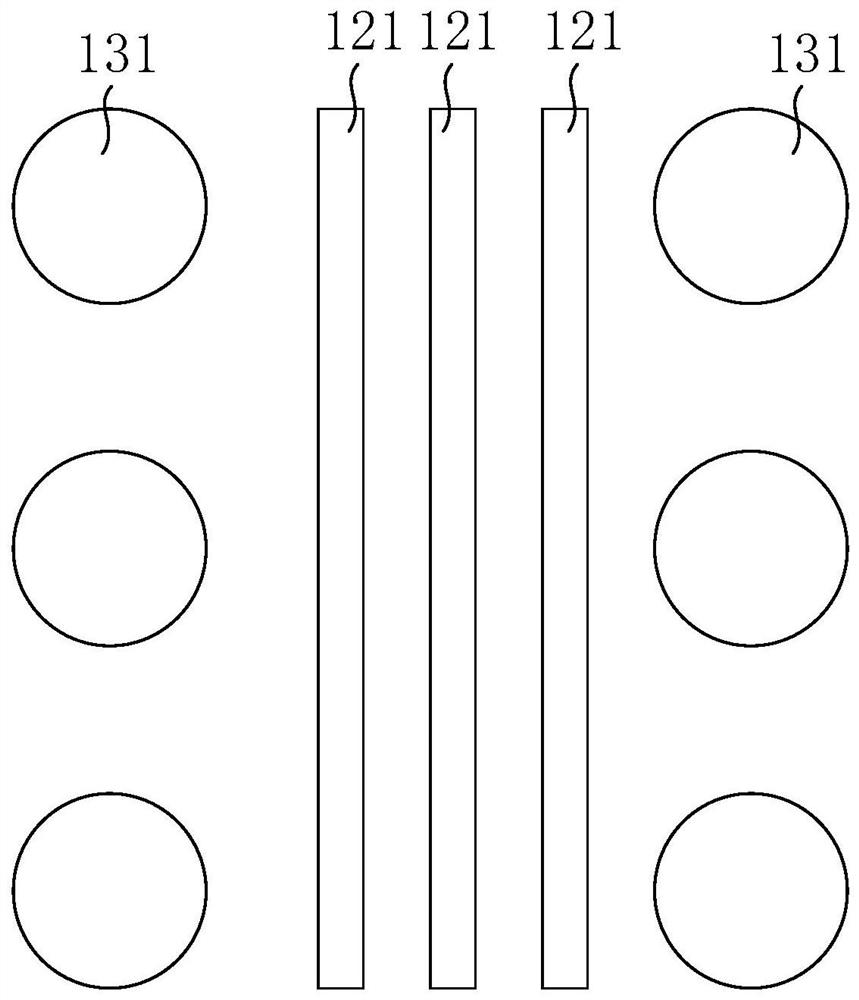

[0042] Such as Image 6 As the second embodiment of the present application, a display panel is disclosed. The display panel includes an array substrate 100 and a box substrate. The array substrate 100 includes: a substrate 110, a 110 on the peripheral wiring layer 120, the peripheral color resistance layer 130 and a plurality of first spacers 140, the peripheral color resistance layer 130 is arranged on the peripheral wiring layer 120, the peripheral color resistance layer 130 includes A plurality of peripheral color resists 131 , the peripheral wiring layer 120 includes a plurality of peripheral wirings 121 , and a plurality of first spacers 140 are correspondingly disposed on the plurality of peripheral color resists 131 . The projection of the peripheral color resist 131 and the peripheral wiring 121 on the substrate 110 does not overlap.

[0043] Specifically, the design of the spacer in the second embodiment is as Image 6 The schematic diagram of the first spacer 140 ...

Embodiment 3

[0051] Such as Figure 8 As shown, as the third embodiment of the present application, the present application also discloses a display panel. The display panel includes: an array substrate 100, a cell substrate and a liquid crystal layer; the cell substrate is arranged opposite to the array substrate 100, and the liquid crystal A layer is disposed between the cell-aligning substrate and the array substrate 100 . The array substrate 100 can be selected from different array substrates 100 in the above-mentioned embodiments. In the selection such as Image 6 On the array substrate 100 in the display panel shown, this embodiment makes certain improvements to the box substrate on the basis of the second embodiment, specifically as follows Figure 8 Shown:

[0052] A black matrix 145 is arranged on the box-matching substrate, and the black matrix 145 is arranged in an area corresponding to the peripheral wiring. The black matrix 145 of the box-matching substrate abuts against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com