Preliminary cleaning device for cosmetic bottle recycling

A technology for preliminary cleaning and cosmetics, which is applied in the directions of cleaning hollow objects, drying gas arrangement, chemical instruments and methods, etc., can solve the problems of time-consuming and low working efficiency of cosmetic bottles, saving physical strength, reducing waiting time, cleaning clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

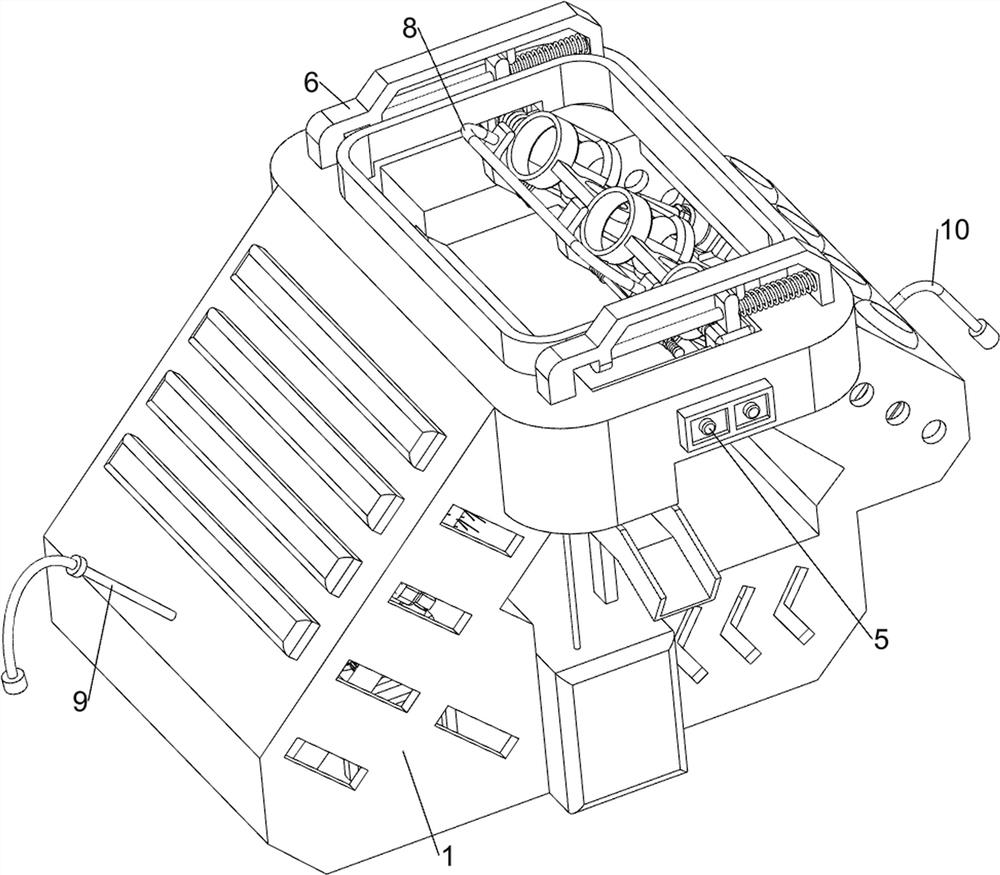

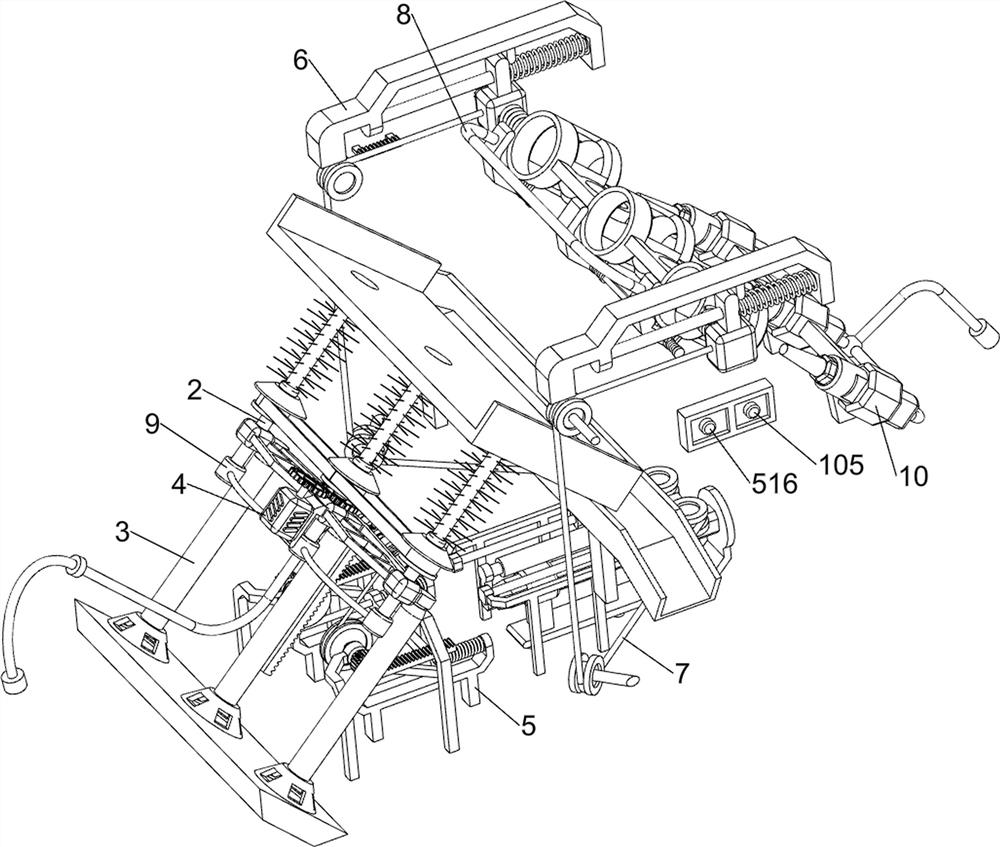

[0090] A preliminary cleaning device for recycling cosmetic bottles, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a box body 1, a hair brush 2, an installation mechanism 3, a drive mechanism 4 and a propulsion mechanism 5, and the left side of the box body 1 is provided with an installation mechanism 3, and the installation mechanism 3 is provided with a hair brush 2, and the installation mechanism 3 A driving mechanism 4 is arranged on the upper side, and a propulsion mechanism 5 is arranged on the lower side inside the box body 1 .

[0091] The installation mechanism 3 includes a sliding cylinder 31, a sliding shaft 32, a mounting seat 33 and a connecting frame 34. Three sliding cylinders 31 are evenly spaced on the lower left side inside the box body 1, and the sliding cylinder 31 is provided with a sliding shaft 32 inside. The right side of the sliding shaft 32 is provided with a mounting seat 33, and the mounting seat 33 is rotatably conn...

Embodiment 2

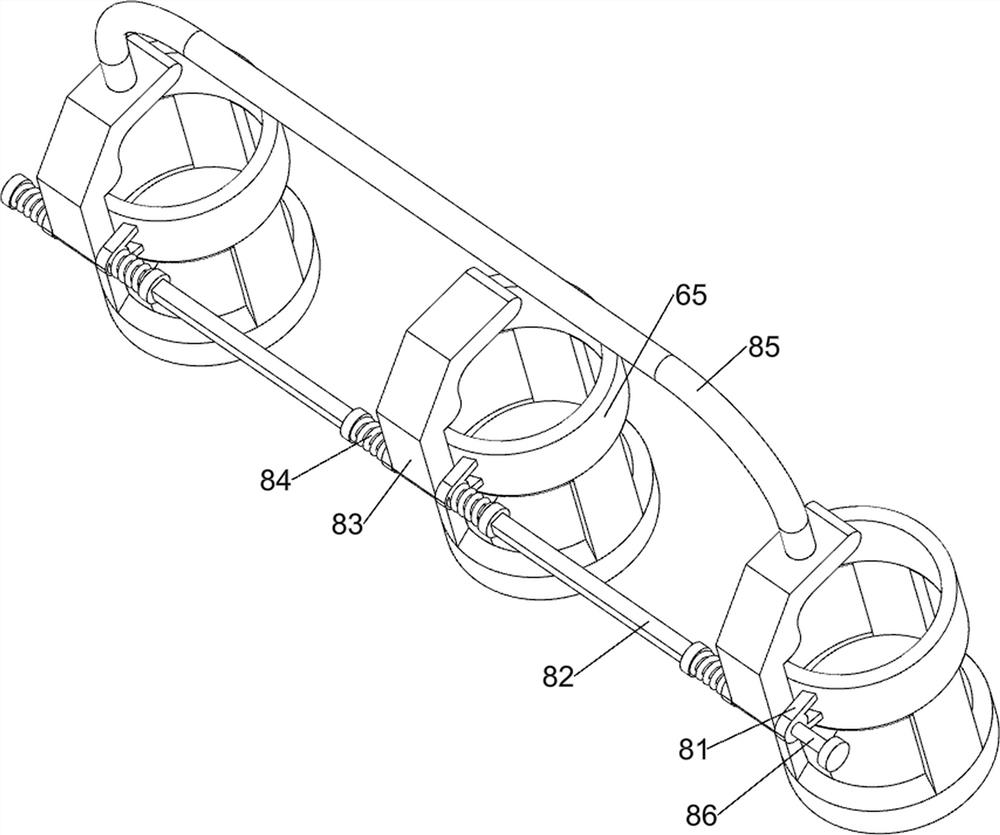

[0096] On the basis of Example 1, such as figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, it also includes a placement assembly 6, and the placement assembly 6 includes a guide frame 61, a sliding seat 62, a return spring 63, a turret 64, a placement cylinder 65, a fourth gear 66, a second rack 67 and a first torsion spring 68, the top of the box body 1 is symmetrically provided with a guide frame 61 front and back, the guide frame 61 is provided with a sliding seat 62, the right side of the slide seat 62 is provided with a return spring 63 between the guide frame 61 on the same side, and the slide seat Between 62 lower parts, a turret 64 is provided for rotation, on which three placement tubes 65 are evenly spaced, a fourth gear 66 is provided on the rear side of the turret 64, and a second rack is provided on the upper rear side of the inner side of the box body 1. 67 , the second rack 67 cooperates with the fourth gear 66 , and a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com