Hardware bending machine

A bending machine and hardware technology, applied in the field of hardware, can solve the problems of different bending machines, danger, and workpieces leaving the machine, etc., to achieve the effects of optimizing bending effect, improving functionality, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

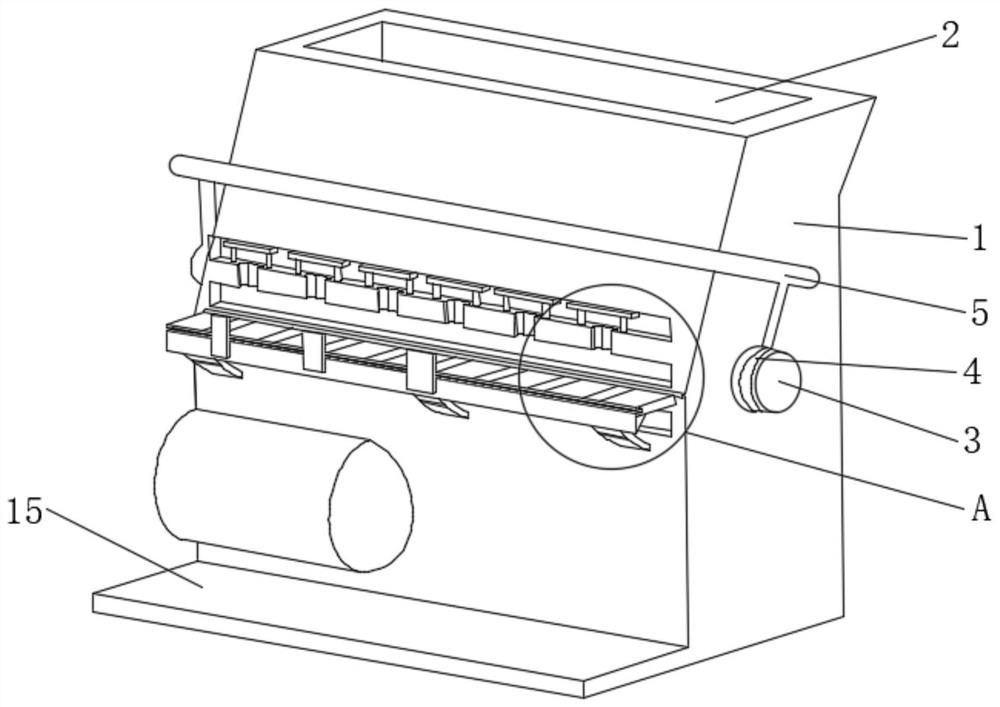

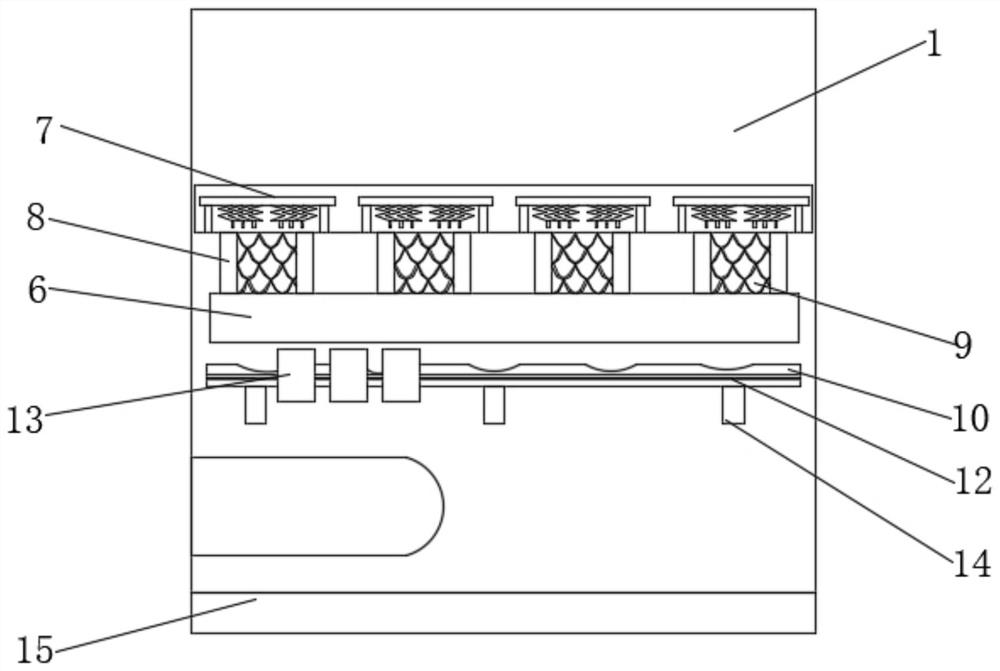

[0034] see Figure 1-2 , the present invention provides a technical solution: a bending machine for hardware, including a chassis 1, the top of the chassis 1 is provided with a heat dissipation window 2, the left and right sides of the outer surface of the chassis 1 are fixedly connected with a fixed plate 3, the fixed plate The outer surface of 3 is provided with a strip groove 4, and two strip grooves 4 are provided with two. The inner surfaces of the two strip grooves 4 are fixedly connected with fixing rods, and the opposite sides of the two fixing rods are fixedly connected with a safety rod. Bar 5, the outer surface of safety bar 5 is covered with rubber sleeve, the outer surface of chassis 1 is provided with transverse groove 6 successively from top to bottom, and there are three transverse grooves 6, and the inner surface of upper transverse groove 6 is evenly fixedly connected with a stable Mechanism 7, the bottom of the upper horizontal groove 6 is uniformly provided...

Embodiment 2

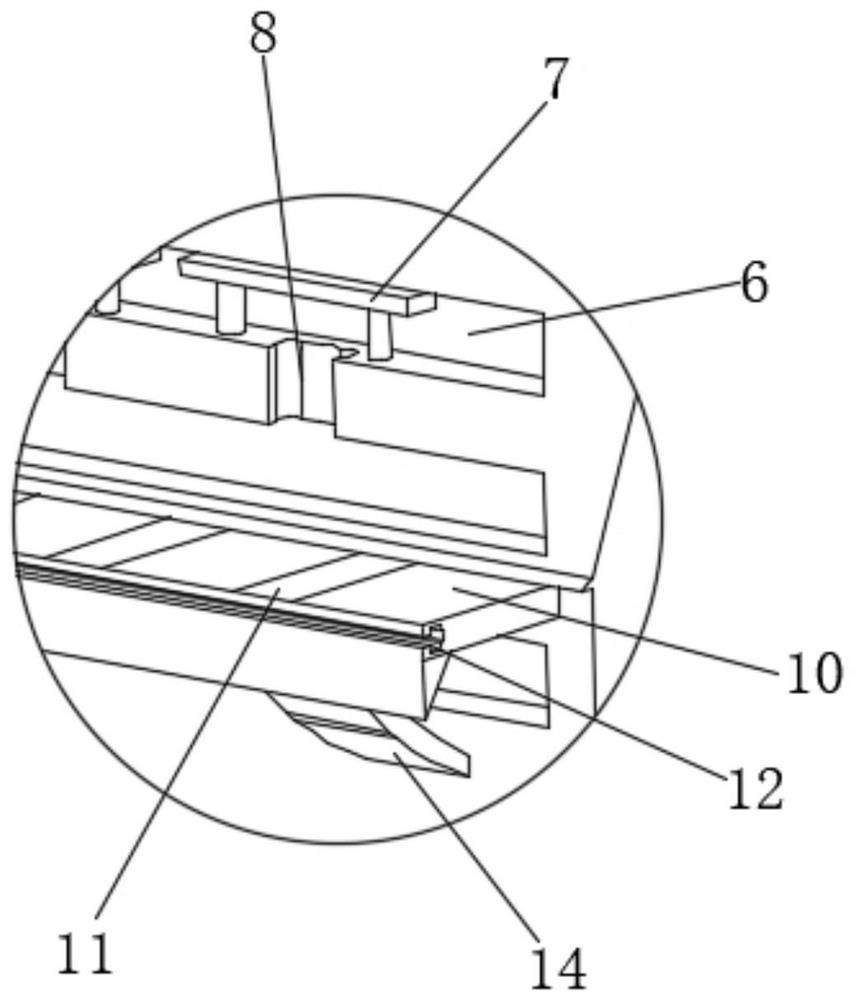

[0036] see Figure 1-3 , the present invention provides a technical solution: the stabilizing mechanism 7 includes a vertical rod 71, the bottom of the vertical rod 71 is fixedly connected with the bottom of the inner surface of the upper horizontal groove 6, and the tops of the two vertical rods 71 are fixedly connected with a baffle 72, the baffle Both left and right sides of the bottom of the 72 are fixedly connected with a telescopic platform 73, and the bottom of the telescopic platform 73 is evenly and fixedly connected with a limiting column 74. Prevent the workpiece from detaching from the outer surface of the work plate 10 and the upward movement of the workpiece may cause extrusion to the transverse groove 6. When the workpiece is upwardly extruded, by contacting the telescopic table 73, the distance of the upward movement of the hardware workpiece is controlled. Excessive death causes the hardware to bend.

Embodiment 3

[0038] see Figure 2-7 , the present invention provides a technical solution: the anti-skid mechanism 9 includes a conical bottom block 91 connected, the bottom of the conical bottom block 91 is fixedly connected with the inner wall of the special-shaped groove 8, and the outer surface of the conical bottom block 91 is rotatably connected with an upper cover plate 92 , a connection mechanism 93 is provided between the bottom of the upper cover plate 92 and the bottom of the conical bottom block 91 . The internal space of the special-shaped groove 8 is reduced, thereby preventing the workpiece from continuing to move upward, and controlling the workpiece to produce a large displacement action.

[0039] The connection mechanism 93 includes a connection belt, and the left and right ends of the connection belt are respectively fixedly connected to the inner surface of the upper cover plate 92 and the inner surface of the conical bottom block 91 .

[0040] The bottom of the upper ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap