Automatic plug pin adding mechanism for granular chip storage material pipe

A material tube and plug nail technology, which is applied in the field of automatic plugging nail mechanism for granular chip storage material tubes, can solve the problems of inability to meet mass industrial production and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

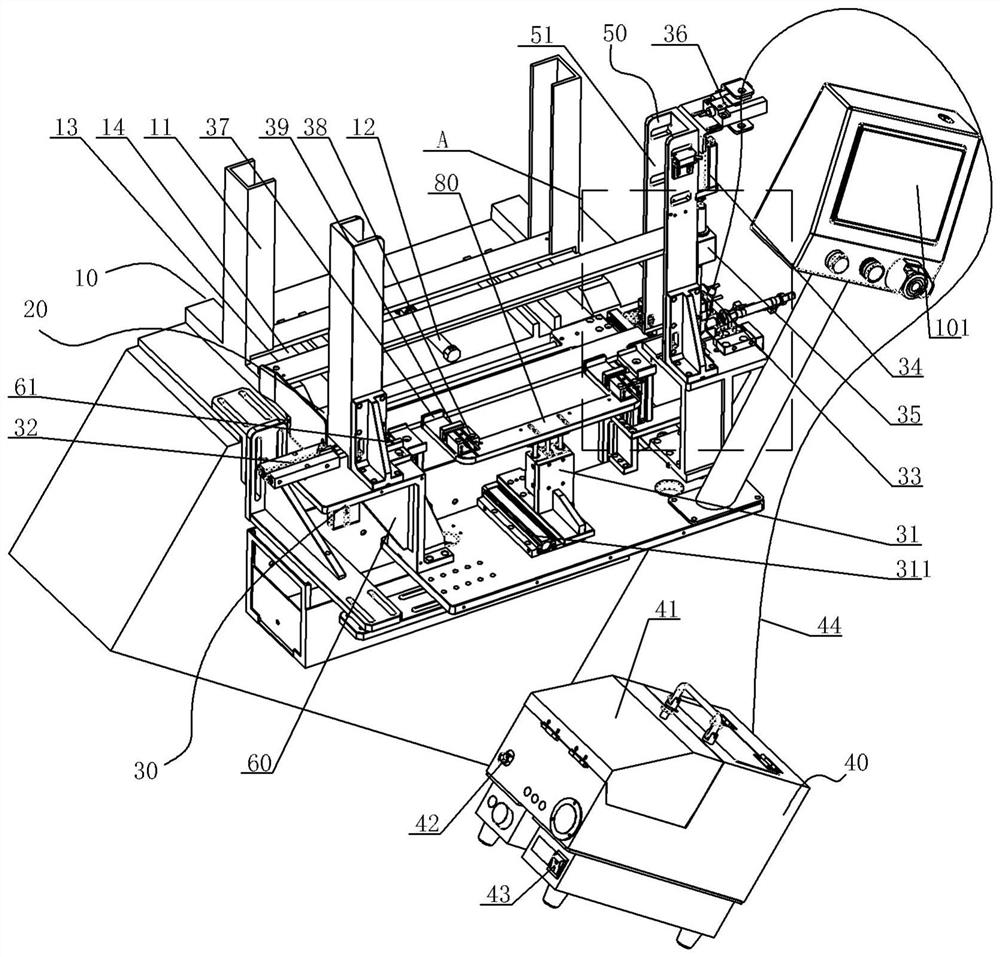

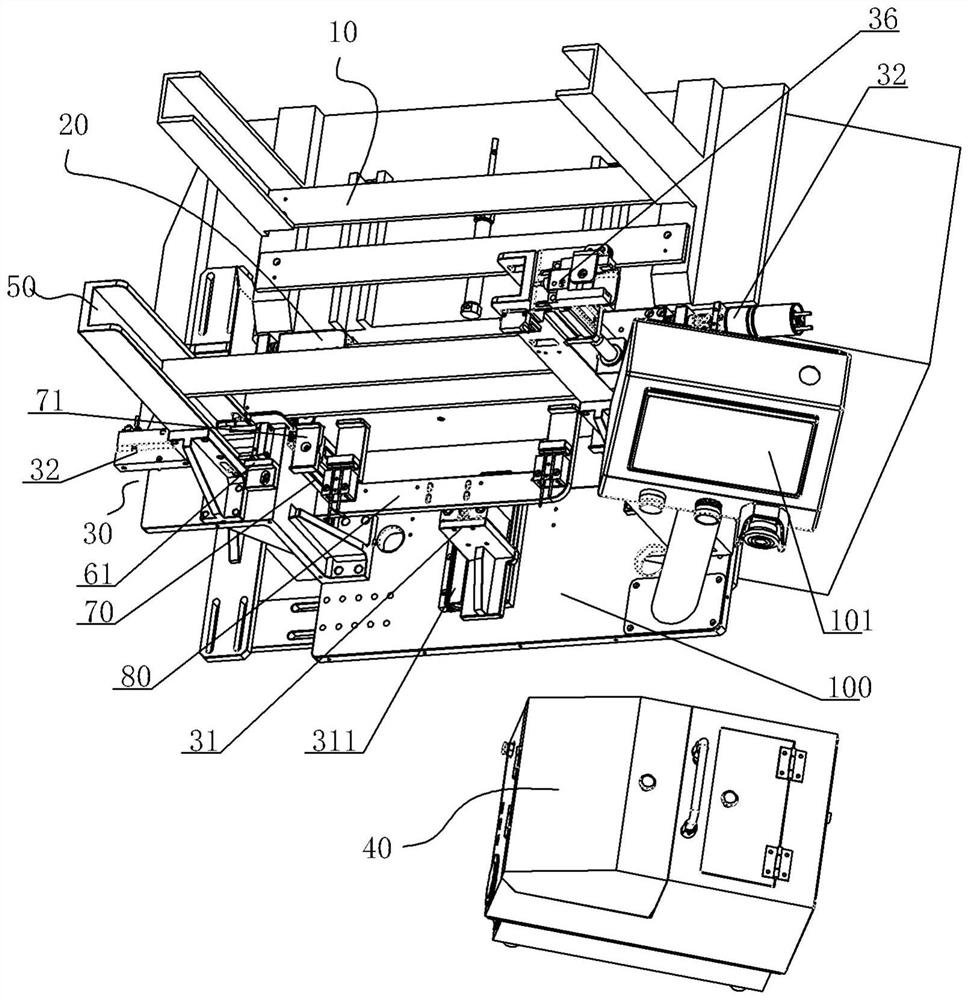

[0027] A mechanism for automatic plugging nails in storage tubes for granular chips, see Figure 1-Figure 3 , which includes a material tube loading mechanism 10, a material tube transition conveying line 20, a material tube plugging machine 30, and a plug feeding machine 40;

[0028] The output end of the material tube loading mechanism 10 is connected to the input end of the material tube transition input line 20, and the output end of the material tube transition input line 20 is arranged toward the material tube plugging machine 30;

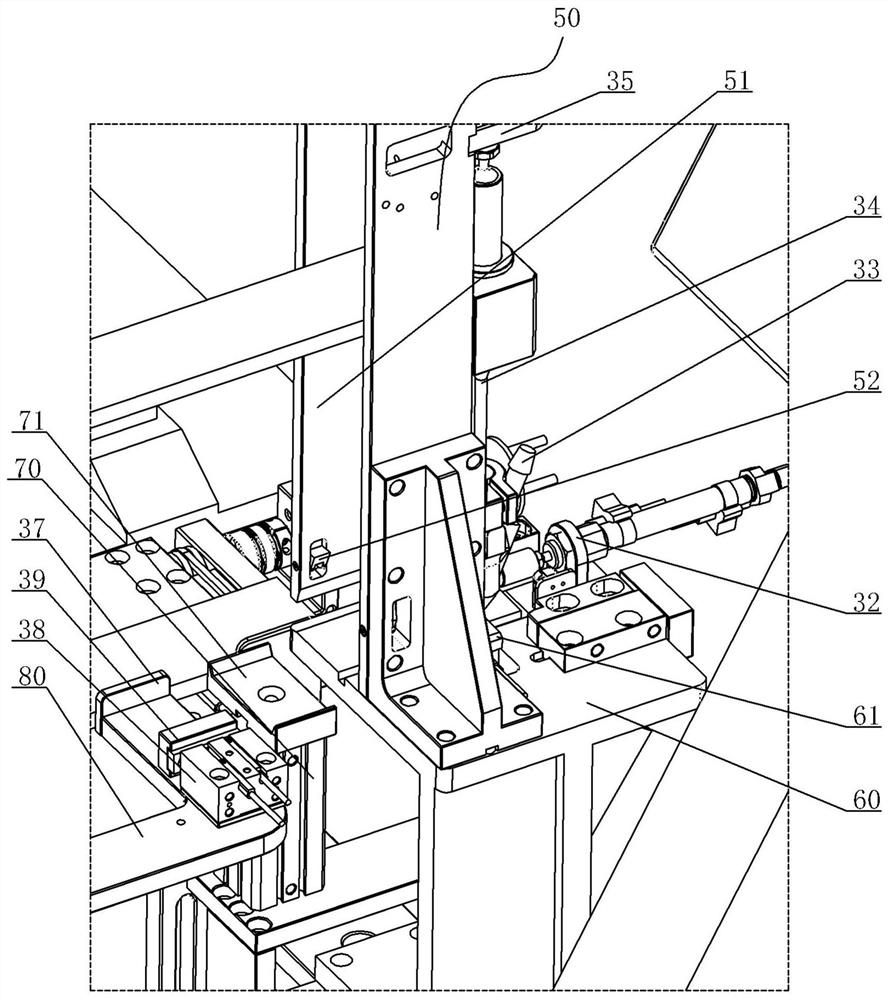

[0029] The material tube plugging and nailing machine 30 includes a material receiving channel 50 and a positioning support seat 60 on both sides. The position is also respectively provided with the material pipe jacking cylinder 70, the top of the material pipe jacking cylinder 70 is provided with a jacking positioning plate 71, the upper surface of the jacking positioning plate 71 is provided with a profiling material tube width is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com