AGV trolley material conveying system and control method thereof

A conveying system, trolley technology, applied in transportation and packaging, storage devices, etc., can solve problems such as wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

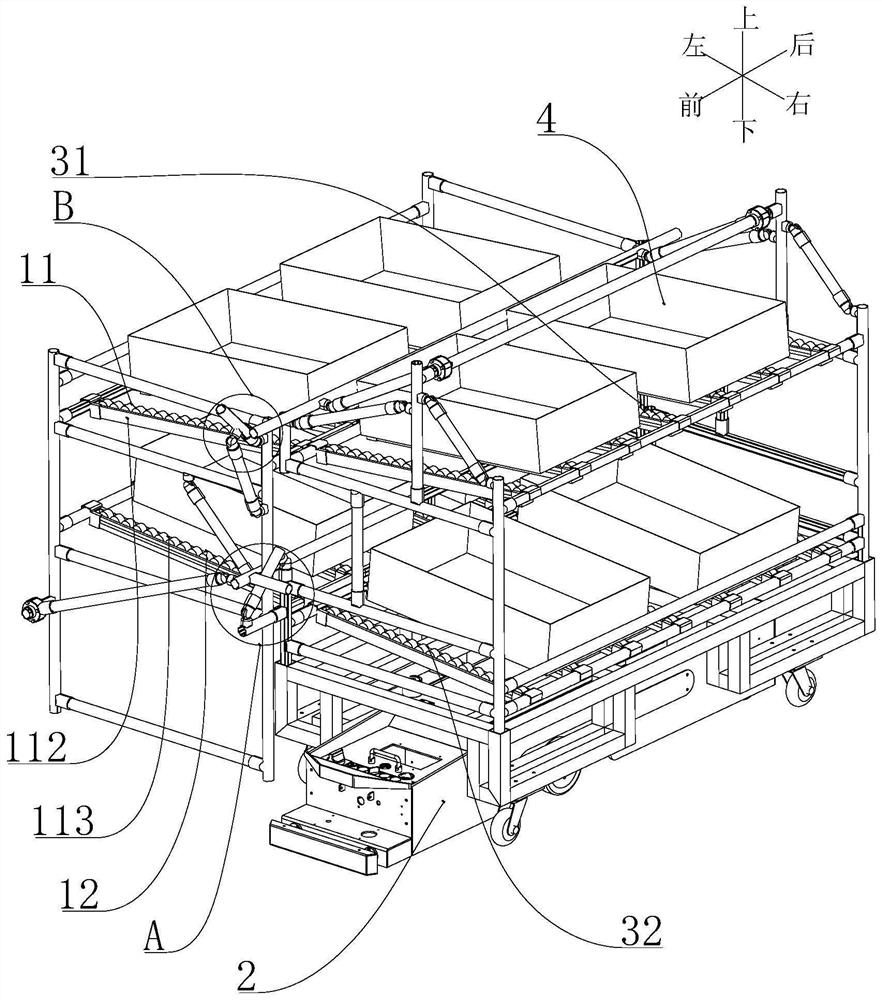

[0064] An AGV trolley material delivery system of the present invention, comprising:

[0065] AGV trolley 2, please refer to figure 1 As shown, the purpose of pulling the mobile trolley 3 to move is played, and the mobile trolley 3 is connected to each other through a hook. The specific structure of the AGV trolley 2 is the prior art, and it will not be stated too much here. The AGV trolley 2 can not only serve as The movement of the mobile car 3 provides power, and the AGV car 2 can also realize automatic walking according to a predetermined path. The path requirements and its speed have certain requirements. Therefore, the selection of AGV car 2 here can meet the design requirements.

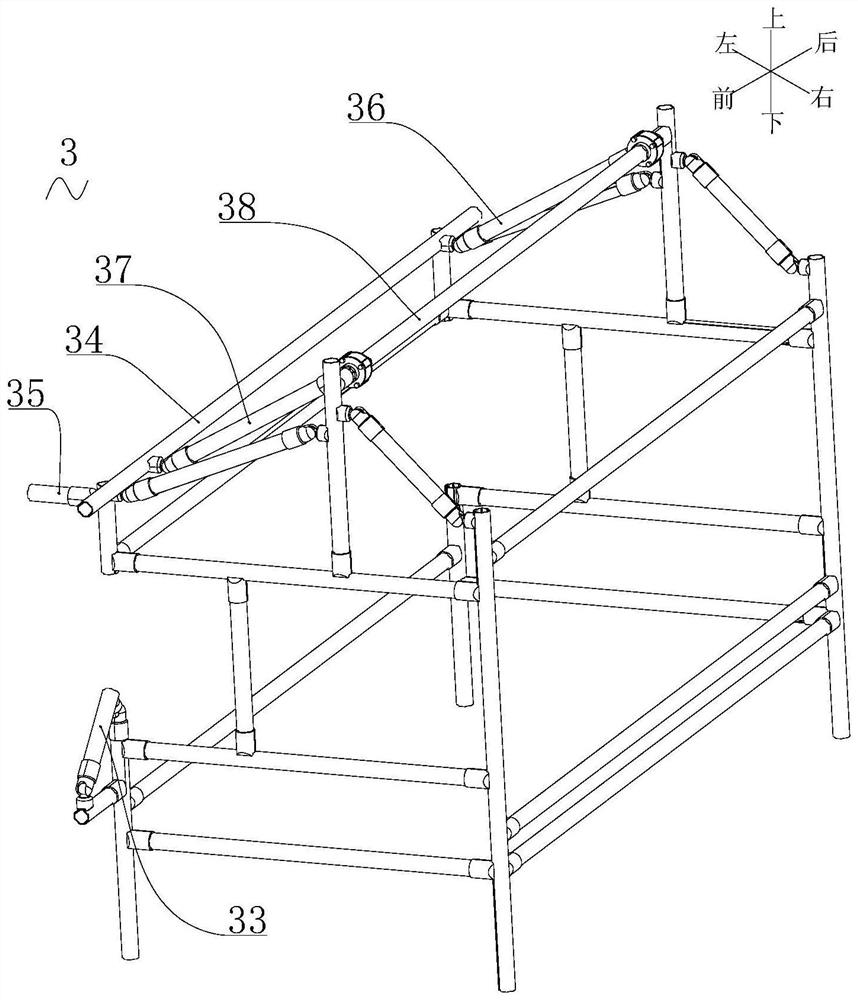

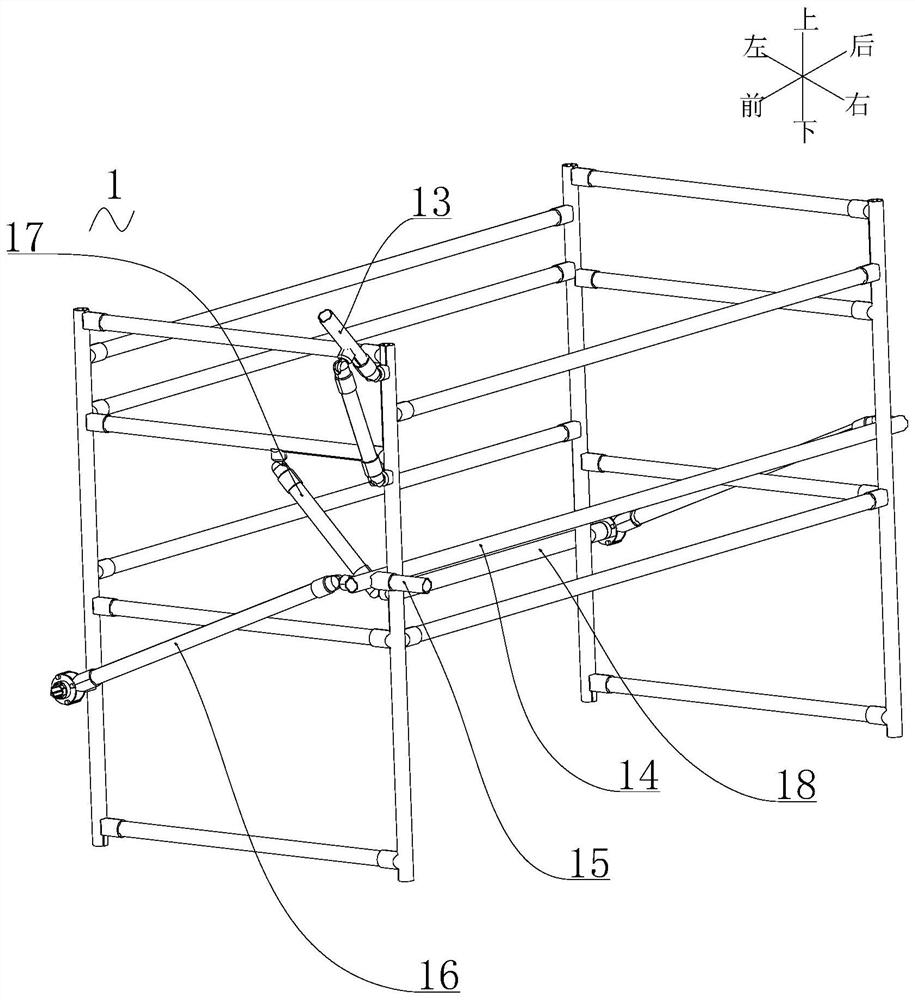

[0066] The material rack 1 is fixed beside the line, and the assembler stands beside it, and carries out the assembly of the automobile by taking the parts in the turnover box 4 on the first material rack layer 11, please refer to image 3 shown, combined with Figure 4 As shown, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com