Local transformation process for steel spring floating slab ballast bed

A technology of partial reconstruction and floating slab, applied in the directions of roads, tracks, ballast layers, etc., can solve problems such as uneven settlement of sleepers, and achieve the effects of eliminating current defects of lines, improving track equipment status, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

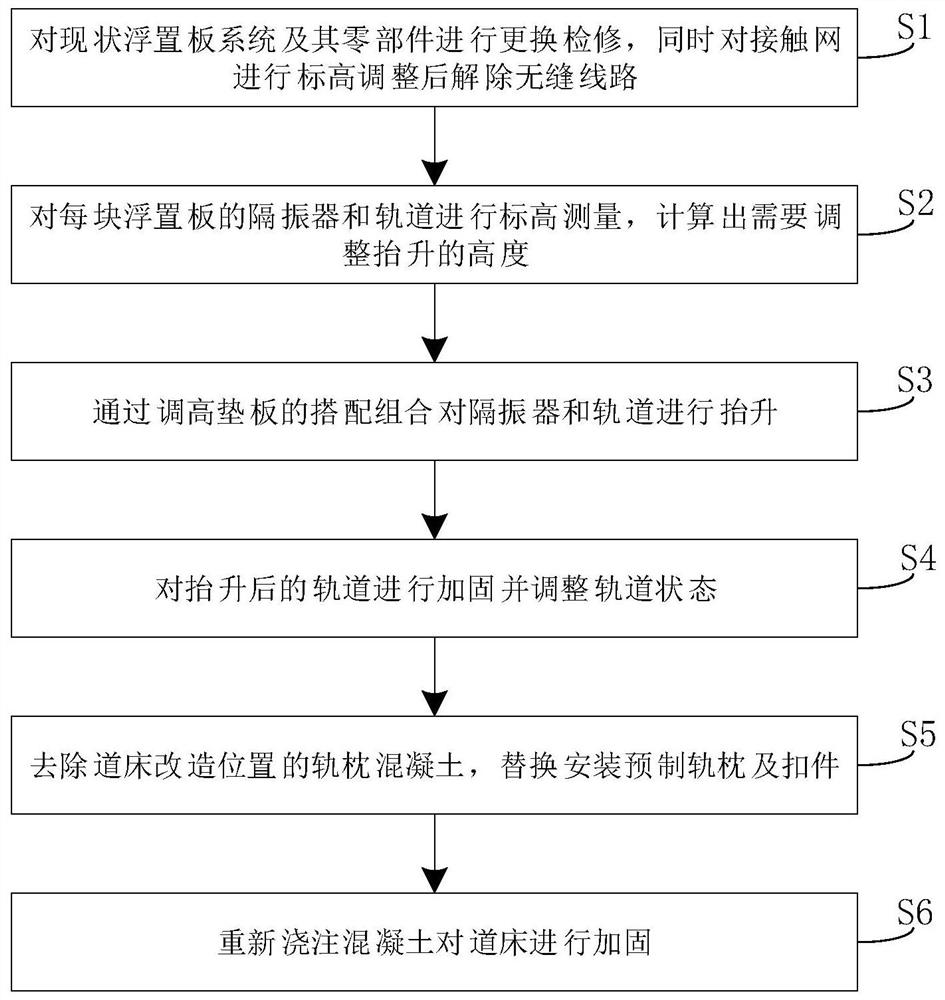

[0039] Such as figure 1 The partial transformation process of the steel spring floating slab ballast bed shown specifically includes the following steps:

[0040] S1. Replace and overhaul the current floating slab system and its parts, and at the same time adjust the elevation of the catenary and remove the seamless line;

[0041] S2. Measure the elevation of the vibration isolator and track of each floating plate, and calculate the height that needs to be adjusted for lifting;

[0042] S3. Lift the vibration isolator and the track through the matching and combination of the heightening pad;

[0043] Specifically, the lifting adjustment of the vibration isolator specifically includes the following steps: firstly, determine the design elevation of the ballast bed reconstruction; then place 1-1.2m intervals on the vibration isolators of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com