Construction method of green upgrading and reconstruction of old cement concrete pavement

A technology for concrete pavement and upgrading, which is applied to roads, roads, road repair, etc., can solve the problem that it is difficult for construction workers to judge and distinguish disease treatment measures, and achieve the effect of avoiding the deep spread of cracks, improving the effect and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

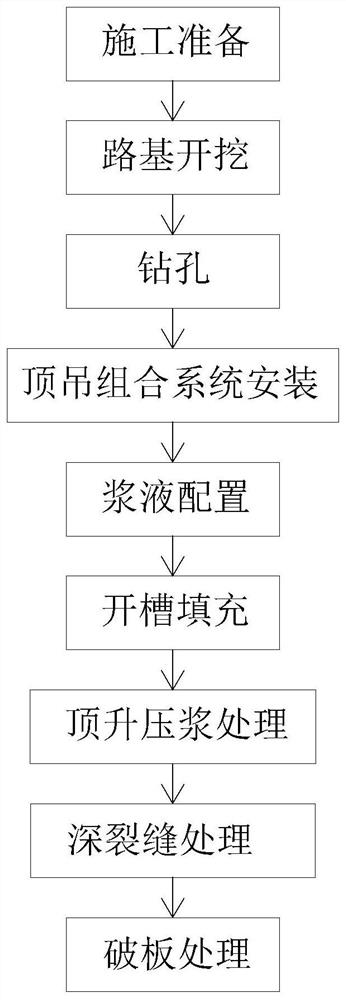

[0085] Such as figure 1 As shown, the green upgrading and reconstruction construction method of old cement concrete pavement disclosed by the present invention includes the following steps: S1 construction preparation, S2 subgrade excavation, S3 drilling, S4 top crane combined system installation, S5 grout configuration, S6 groove filling, S7 jacking grouting treatment, S8 deep crack treatment, S9 broken plate treatment. When there are many diseases on the original pavement, follow this procedure for construction.

[0086] S1 construction preparation:

[0087] S1.1 Detection and analysis, detect and analyze the diseased pavement, detect the deflection value measured at 2 single points of the road slab on the diseased pavement, the deflection difference measured at the two sides of the joint, or detect the depth and width of the reflective crack; If the measured deflection value of a point is less than 0.14mm, the corresponding road surface will not be processed; when the mea...

Embodiment 2

[0132] Such as Figure 10 As shown, the green upgrading and reconstruction construction method of old cement concrete pavement disclosed by the present invention includes the following steps: S1 construction preparation, S2 subgrade excavation, S3 drilling, S4 top crane combined system installation, S5 grout configuration, S6 groove filling, S7 jacking grouting treatment, S8 deep crack treatment, S9 broken plate treatment. After completing the construction preparation of step S1 and determining the classification and treatment of pavement diseases, the steps of S6 slot filling, S7 jacking grouting treatment, S8 deep crack treatment, and S9 broken slab treatment are respectively selected, among which step S7 jacking grouting treatment Before the treatment, S2 subgrade excavation, S3 drilling, S4 top crane combined system installation, and S5 grout configuration are required.

[0133] When there are many diseases on the original pavement, follow this procedure for construction....

Embodiment 3

[0181] Based on embodiment 1, embodiment 2, as Figure 11 , Figure 12 As shown, the deep crack treatment in step S8 can be carried out in the following construction methods:

[0182] S8.1 Milling: Use a concrete slotting machine to mill the two original road panels in steps to form a step groove 20, and mill to the bottom of the deep crack 25; the step groove 20 has at least three layers, and the inner wall of the bottom step It is an inclined plane; the milled waste is cleaned up and watered to soak the concrete pavement on both sides of the step groove 20;

[0183] S8.2 Install the reinforcement frame: put the reinforcement frame tied with the horizontal reinforcement 33 and the longitudinal reinforcement 34 into the bottom groove, and the upper end of the reinforcement frame is equipped with a horizontal strut 35 along the horizontal direction; there are many horizontal struts 35, Evenly laid; the outer end of the transverse rib 33 is bent upwards or downwards; the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com