Pile foundation reinforcement cage position control device and installation method

A technology of a pile foundation reinforcement cage and a control device, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as inability to effectively fix reinforcement cage reinforcement cages and inconvenience in hoisting reinforcement cages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

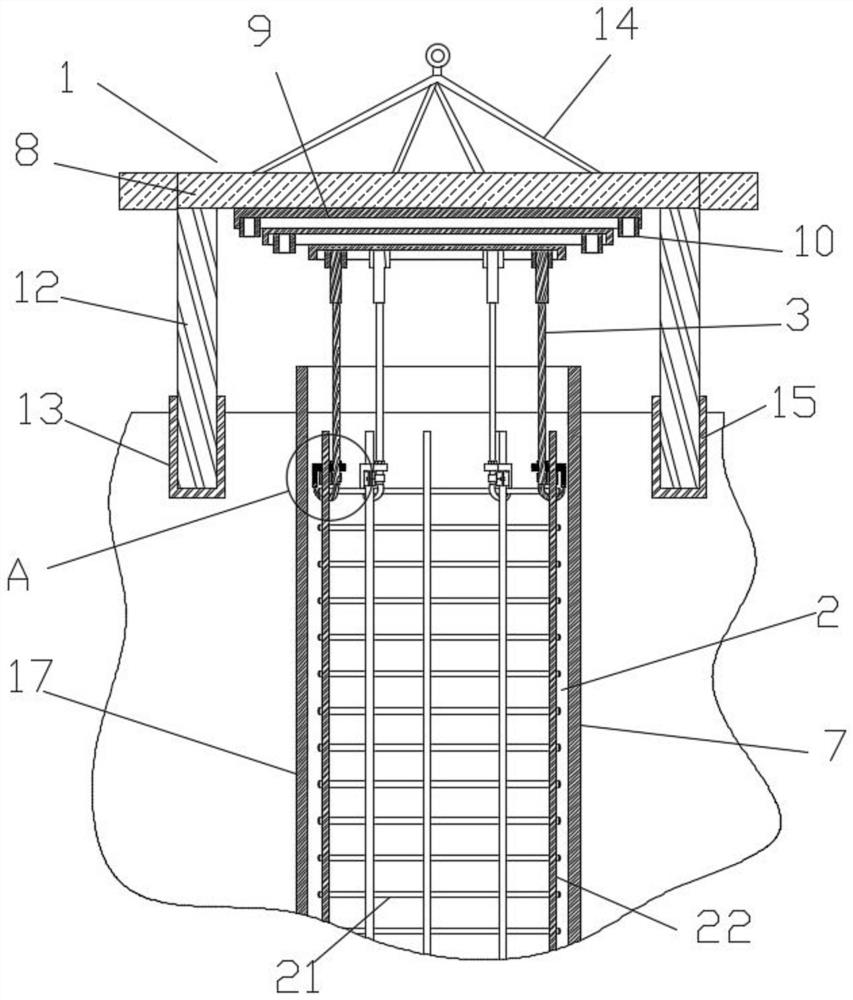

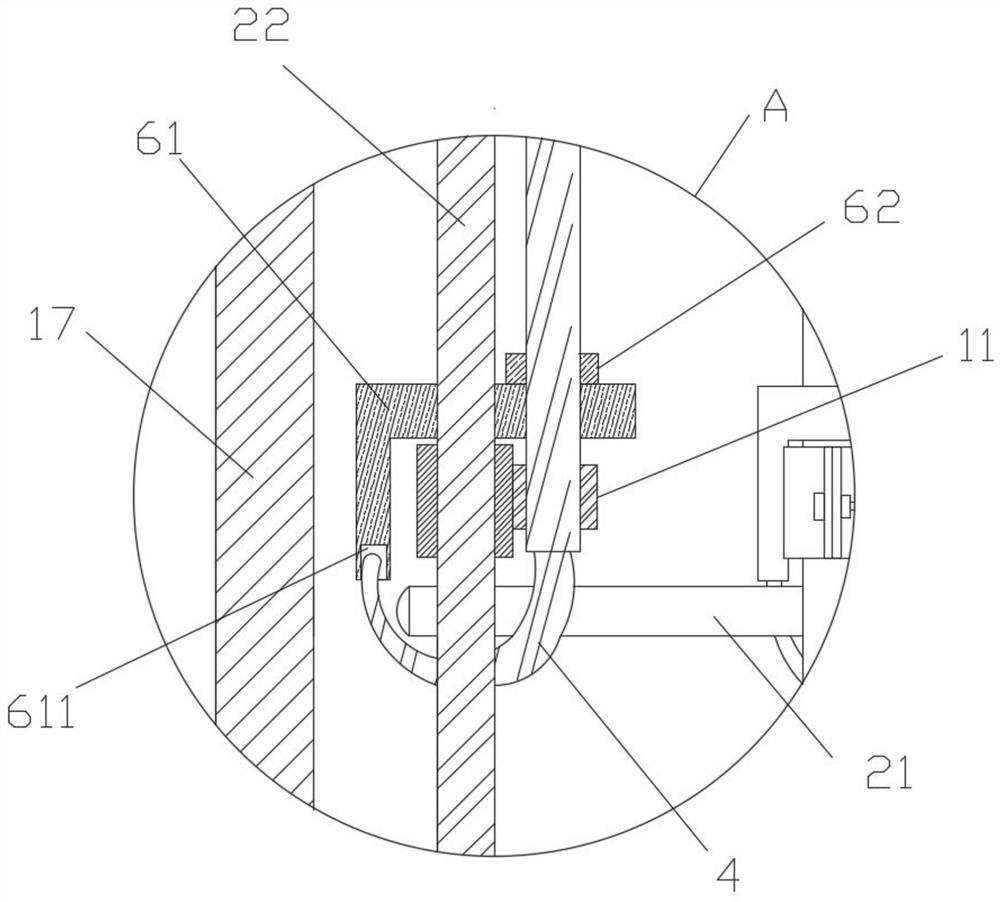

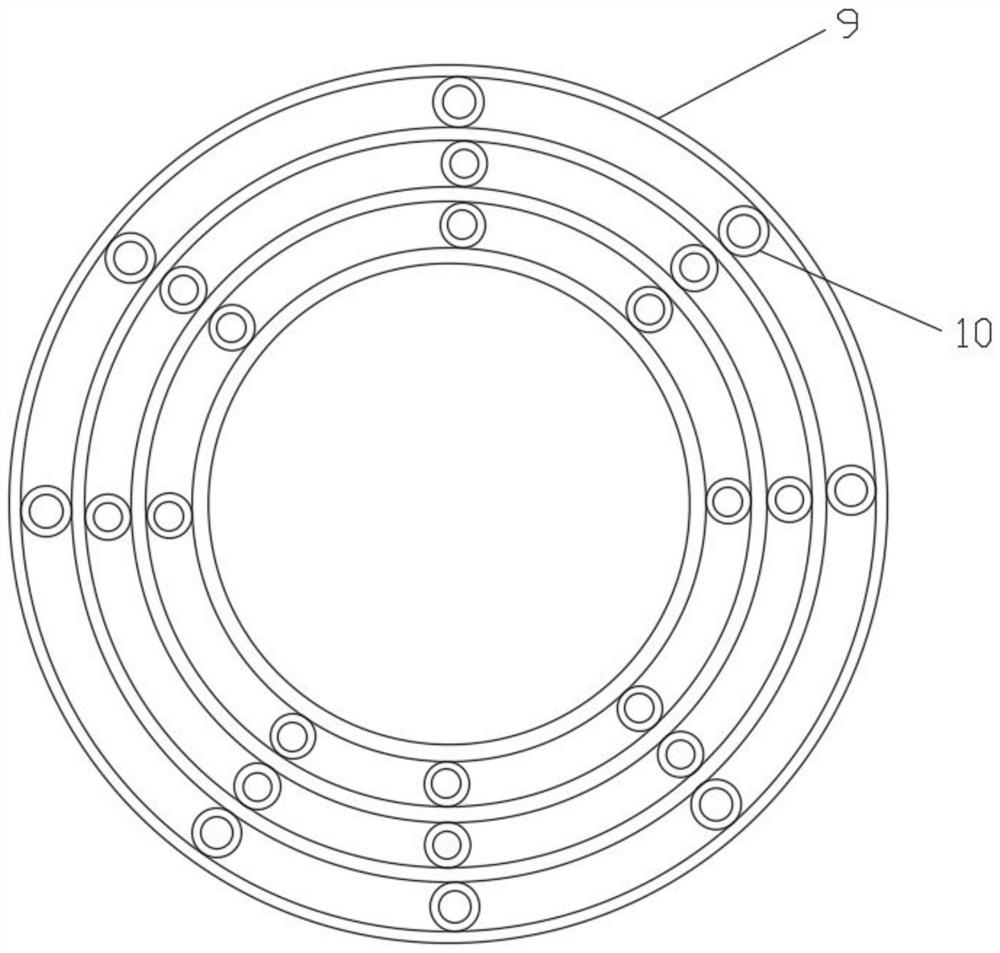

[0034] like Figure 1 to Figure 4 As shown, it is an embodiment of the present invention, a pile foundation reinforcement cage position control device, including a positioning frame 1 and a reinforcement cage 2, the positioning frame 1 is installed with a connector 3, and the connector 3 is provided with at least four groups, The upper ends of the multiple sets of connectors 3 are welded with the positioning frame 1, and the bottom ends of the connectors 3 are installed with a bearing portion 4, a connecting portion 5 and a limiting portion 6, and the bearing portion 4 is suitable for supporting the stirrups 21 of the reinforcement cage 2, connecting The part 5 is suitable for connecting to the main rib 22 of the reinforcement cage 2, the connecting part 5 is installed between the bearing part 4 and the limiting part 6, the connecting part 5 is movably connected on the connecting part 3, and the limiting part 6 is installed on the connecting part 5 At the upper end of the cage...

Embodiment 2

[0050] like Figure 5 As shown, it is another embodiment of the present invention. On the basis of Example 1, the bearing part 4 includes a circular plate, which is fixedly connected with the connecting piece 3, and the circular plate is suitable for supporting the stirrup 21, and the limit plate 61 Including the arc side, the circular plate is provided with a socket groove 41, the arc side is adapted to the socket groove 41, and the limit plate 61 is suitable for snapping downward in the socket groove 41, and the socket groove 41 and the limit The closing of the bit plate 61 strengthens the actual locking effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap