Orifice sealing and reverse grouting method for in-situ leaching drill hole

A technology of grouting and orifice, which is applied in the directions of sealing/isolation, earthwork drilling and production fluid, etc. It can solve the problems of scrapped drilling, inaccurate control of the instantaneous injection amount of cement slurry, and fracture of well pipe, etc., and achieves low cost , Easy to promote on a large scale, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

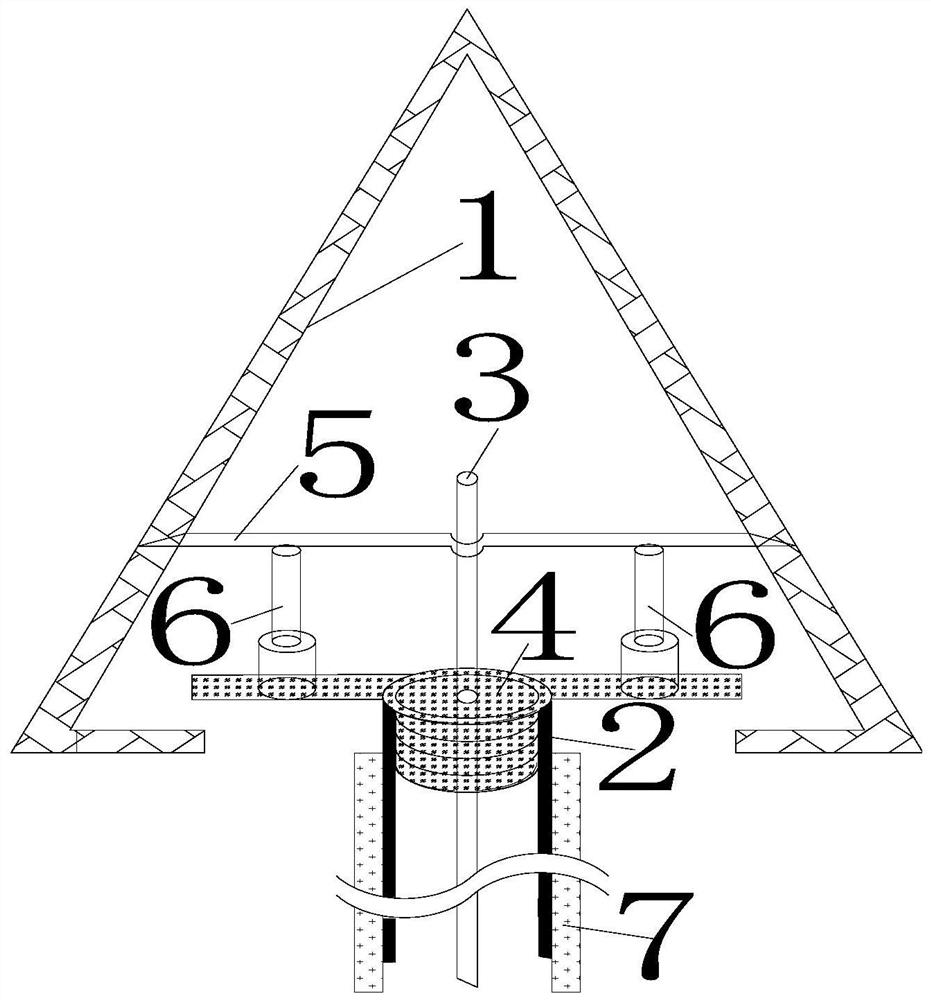

[0042](a) 1-1111 is a liquid injection drill hole in an in-situ leaching uranium mine in Inner Mongolia. The ore layer is located at 302-310 meters underground. It is drilled with a Φ215 roller cone bit and drilled to 310m. The open hole construction is completed. About 250mm; put down the well pipe (2), the well pipe (2) is a Φ100×10 UPVC pipe, connected by a screw, the depth of the screw is 2.5mm, the joint is wrapped with raw material tape and coated with 804 glue, the screw is resistant The pressure is 1.5Mpa, and the well pipe (2) is lowered to a depth of 300m in the open hole;

[0043] (b) Run the grouting pipe (3) into the well pipe (2). The grouting pipe (3) is a Φ40×3.5mm carbon steel pipe connected by a threaded thread with a depth of 1.5mm and a pressure resistance of 2.2Mpa at the joint , the grouting pipe (3) is lowered to a position of 300m, and the outlet position of the bottom end of the grouting pipe (3) is consistent with the depth of the bottom end of the we...

Embodiment 2

[0057] (a) 2-1111 is a drilling hole for pumping liquid in an in-situ leaching uranium mine in Inner Mongolia. The ore layer is located at 402 to 410 meters underground. The Φ311 roller cone bit is used to drill the open hole, and the open hole construction is completed when the hole is drilled to 410m. About 350mm; put down the well pipe (2), the well pipe (2) is a UPVC pipe of Φ152×12, connected by a threaded thread, the depth of the threaded thread is 3.0mm, the joint is wrapped with raw material tape and coated with 804 glue, the threaded thread is resistant to The pressure is 1.6Mpa, and the well pipe (2) is lowered to a depth of 400m in the open hole;

[0058] (b) Run the grouting pipe (3) into the well pipe (2). The grouting pipe (3) is a Φ40×3.5mm carbon steel pipe connected by a threaded thread with a depth of 1.5mm and a pressure resistance of 2.2Mpa at the joint , the grouting pipe (3) is lowered to a position of 400m, and the outlet position of the bottom end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com