Process for quickly repairing damaged shield tunnel structure under special limiting conditions

A shield tunneling technology with limited conditions, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of train operation impact, inability to replace segments, poor integrity, etc., and achieve the effect of meeting structural requirements and shortening repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

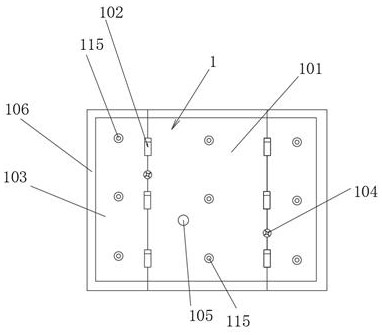

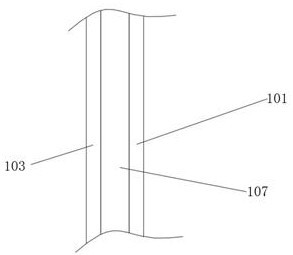

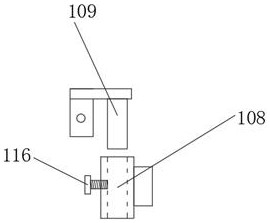

[0040] Example: such as figure 1 , -9, the process of rapid repair of shield tunnel structure damage in a special restrictive condition of the present invention comprises the following steps,

[0041] Step 1. Clean up the damaged segment, level the construction surface, and apply interface treatment to the damaged edge of the cleaned segment, so that the emergency steel closure member can be installed on the side facing the water;

[0042] Step 2. Install steel emergency sealing components according to the size of the damaged surface, and use chemical sealing materials to seal the contact joints between the steel emergency sealing components and the segments for a second time to completely block the sediment and water gushing out of the facing surface, and reinforce the steel plate The connection with the segment makes it a whole;

[0043] Step 3. On the damaged edge of the cleaned segment, paint high-density cement permeable crystalline material for waterproof treatment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com